Manufacturing method of blind-hole compressor impeller

A manufacturing method and impeller technology, which is applied in the field of compressor impeller processing, can solve problems such as difficulty in ensuring precision requirements, low equipment aging precision, and low production efficiency, and achieve the effects of shortening the processing procedure, reducing processing equipment, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

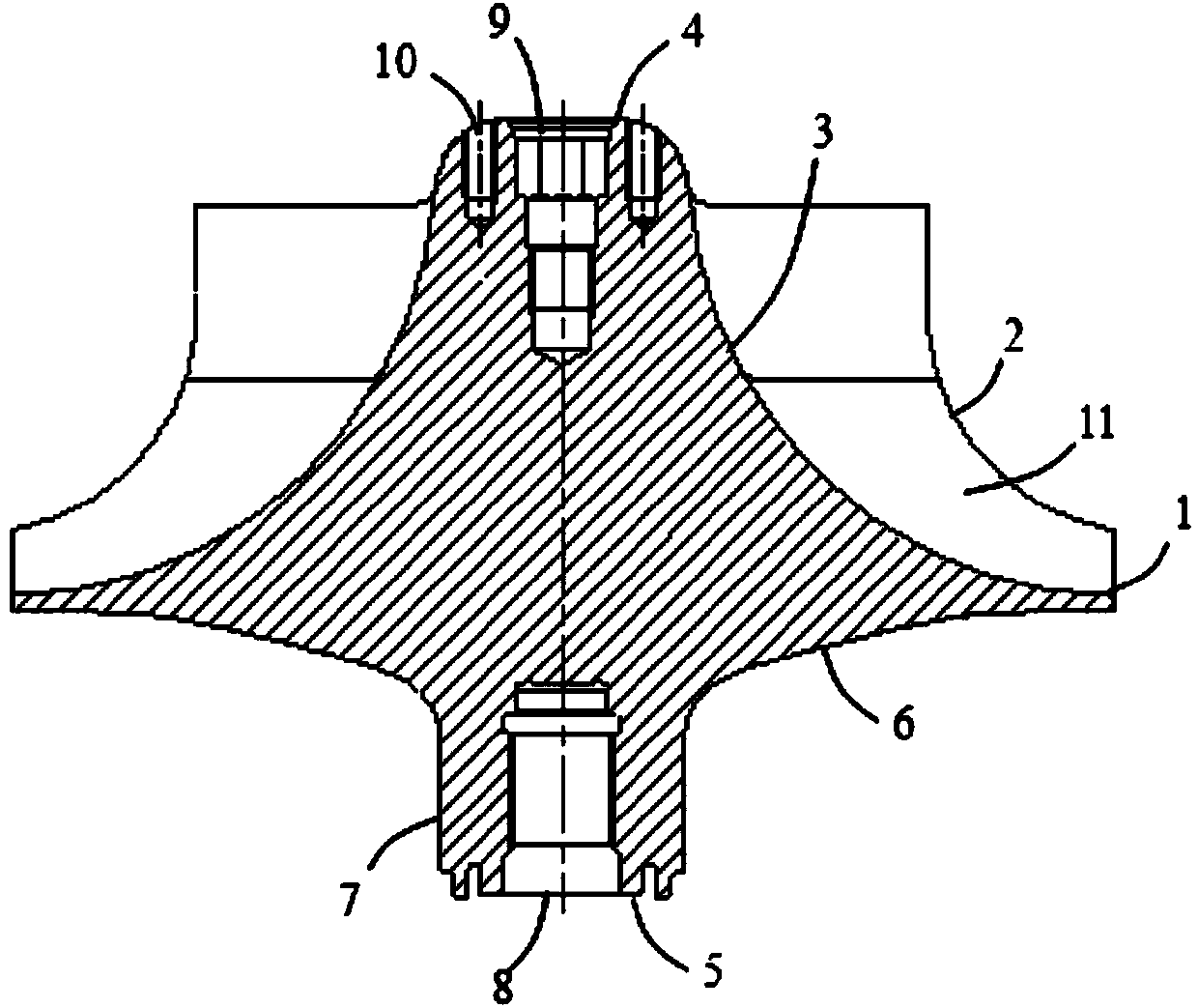

[0013] The manufacturing method of the blind-hole compressor impeller of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0014] see figure 1 , the manufacture method of blind hole compressor impeller of the present invention, comprises the following steps:

[0015] Step 1, clamp the impeller blank on the CNC vertical lathe, turn and process the bottom end face 5, the bottom outer circle 7, the back arc 6 and the large outer circle 1, and process the blind hole 8 with a reamer. The impeller blank is an integral forging die For parts, turning is finishing machining, and the reamer can be a high-precision reamer to ensure machining accuracy. The turning process of the bottom end face 5, the bottom outer circle 7, the back arc 6 and the large outer circle 1 is completed by using the same turning tool to ensure the machining accuracy. After the impeller blank is processed in the first step, it can be detected by a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com