Composite flocculant used in spinning sewage treatment process

A composite flocculant and composite technology, applied in the textile field, can solve the problems of mutagenesis, carcinogenicity, adverse effects on human health and ecological environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

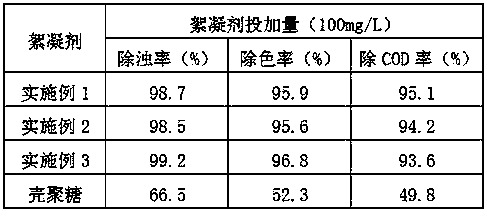

Embodiment 1

[0028] Example 1 A composite flocculant used in the textile sewage treatment process, the raw materials include 11 parts of composite flocculation bacteria F2 and F6, 15 parts of aluminum hydroxide gel, 4 parts of chitosan, wherein chitosan The degree of sugar deacetylation is ≥95%, and the weight ratio of F2 to F6 in the cells of composite flocculogens F2 and F6 is 1.5:1.

[0029] The culture conditions of the composite flocculogens F2 and F6 are as follows: the temperature is 30°C, the rotation speed of the shaker is 135r / min, the culture time is 22h, and the carbon source in the culture process is glucose.

Embodiment 2

[0030] Example 2 A composite flocculant used in textile sewage treatment process, the raw materials include 15 parts of composite flocculation bacteria F2 and F6, 17 parts of aluminum hydroxide gel, 7 parts of chitosan, wherein chitosan The degree of sugar deacetylation is ≥95%, and the weight ratio of F2 to F6 in the cells of composite flocculogens F2 and F6 is 2:1.

[0031] The culture conditions of the composite flocculogens F2 and F6 are as follows: the temperature is 30°C, the rotation speed of the shaker is 140r / min, the culture time is 24h, and the carbon source used in the culture process is glucose.

Embodiment 3

[0032] Example 3 A composite flocculant used in the textile sewage treatment process, the raw materials include 18 parts of composite flocculation bacteria F2 and F6, 19 parts of aluminum hydroxide gel, and 8 parts of chitosan, wherein chitosan The degree of sugar deacetylation is ≥95%, and the weight ratio of F2 to F6 in the cells of composite flocculogens F2 and F6 is 2:1.

[0033] The culture conditions of the composite flocculogens F2 and F6 are as follows: the culture temperature is 30°C, the rotation speed of the shaker is 140r / min, the culture time is 24h, and the carbon source during the culture process is glucose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com