Sludge desanding device, pretreatment device and method for municipal sewage plant

A pretreatment device and technology for urban sewage, applied in the direction of water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problem of poor sludge quality in cement plants, no effect, impure biogas, etc. problems, to achieve the effect of increasing the content of organic matter, facilitating biological treatment, and avoiding sediment deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

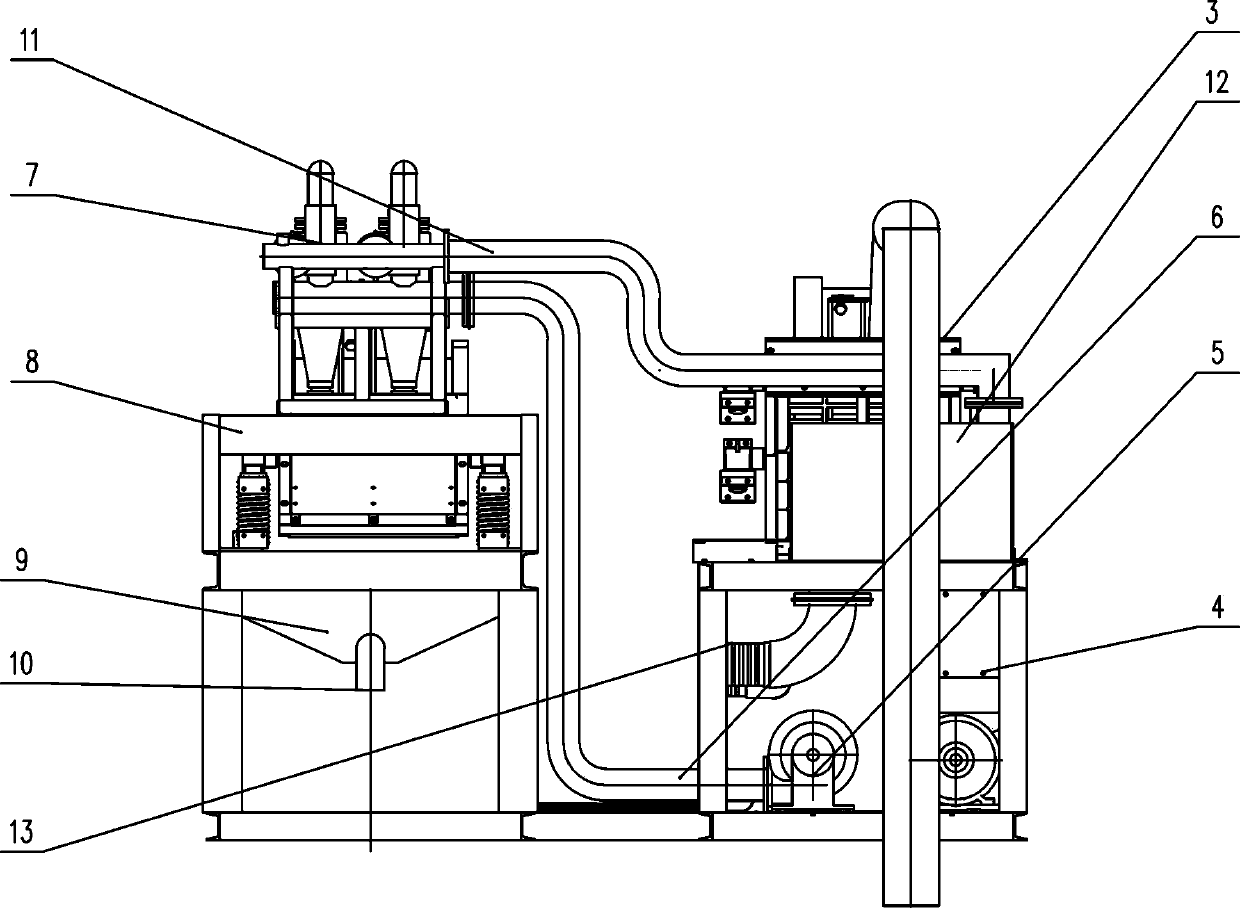

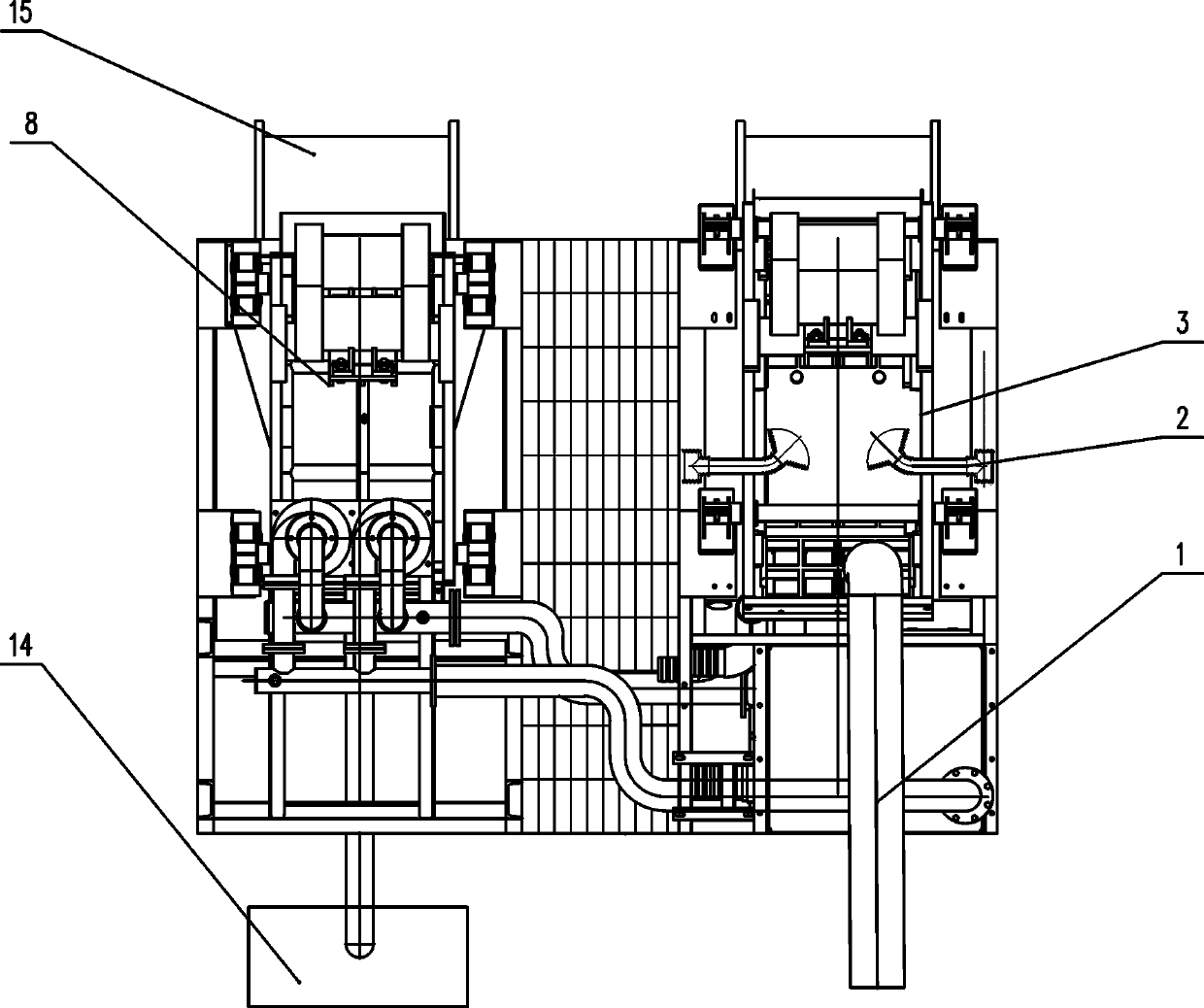

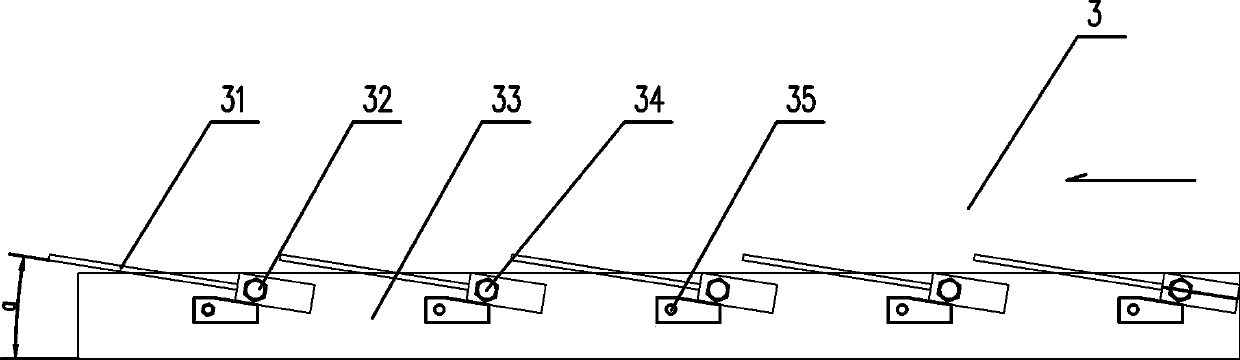

[0040] Such as Figure 1~5 Among them, a sludge removal device for urban sewage treatment plants, including a pretreatment device and a main separation device, the pretreatment device is a pre-screen 3, the top of the pre-screen 3 is provided with multiple rows of bar devices, and the bar devices are along the Arranged obliquely along the flow direction of the sludge, in the rod device, one end of a plurality of rods 31 is fixedly installed on the base 32, and the other end is a free end, and arranged along the flow direction of the sludge. Such as image 3 As shown in , the base 32 is positioned at the upstream of the sludge flow, and the free end of the root bar 31 is positioned at the downstream of the sludge flow. Adopting this structure is convenient for cleaning soft fibrous substances such as hair entangled on the bar 31 .

[0041] The angle a between the bars 31 and the horizontal plane is 0-15 degrees, preferably 8-10 degrees in this example, and the distance between...

Embodiment 2

[0051] Such as Figure 3-5 Among them, a pretreatment device of a sludge desanding device in an urban sewage treatment plant, the top of the pre-screen 3 is provided with multiple rows of bar devices, and the bar devices are arranged obliquely along the flow direction of the sludge. Among the bar devices, there are multiple One end of the bar 31 is fixedly installed on the base 32, and the other end is a free end, and is arranged along the flow direction of the sludge.

[0052] The angle between the rods 31 and the horizontal plane is 0-15 degrees, and the distance between the rods 31 is 2-10 mm.

[0053] The base 32 is connected with the frame 33 of the pre-screen 3 through an adjustable inclination angle.

[0054] Both sides of the base 32 are connected to the frame 33 by adjusting bolts 34 , and a wedge 35 is arranged below the base 32 . This device is used as a core component in Embodiment 1, and the parts that are not described in detail are the same as those in Embodim...

Embodiment 3

[0056] A method for removing sand from urban sewage treatment plant sludge, comprising the following steps:

[0057] 1. Pretreatment

[0058] On the basis of the equipment in Examples 1 and 2, the primary sludge is removed through pre-screening 3 to remove soft fibrous matter and large-grained sand in the primary sludge, and the underflow under the pre-screening 3 screen enters the slurry storage tank 4; pre-screening 3 A flow meter is installed on the slurry inlet pipeline to measure the slurry.

[0059] The top of the pre-screen 3 is provided with multiple rows of rod devices, which are arranged obliquely along the flow direction of the sludge. In the rod device, one end of a plurality of rods 31 is fixedly installed on the base 32, and the other end is a free end. It is arranged along the flow direction of the sludge, and a hydraulic flushing device 2 is installed above the pre-screen 3 to cooperate with the flushing; the soft fiber materials such as hair and large particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com