Suspended cylinder type parallel flow heat storage double hearth kiln

A technology of double-chamber kiln and hanging cylinder is applied in the field of industrial furnace kiln and suspended-cylinder parallel-flow regenerative double-chamber kiln, which can solve problems such as influence on operation safety and service life, poor thermal shock stability of magnesia brick, large thermal expansion coefficient, etc. problems, to achieve the effect of improving cooling effect, improving operational safety, and reducing airflow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. The protection scope of the present invention is not limited to the embodiments, and any changes made by those skilled in the art within the scope defined in the claims also belong to the protection scope of the present invention.

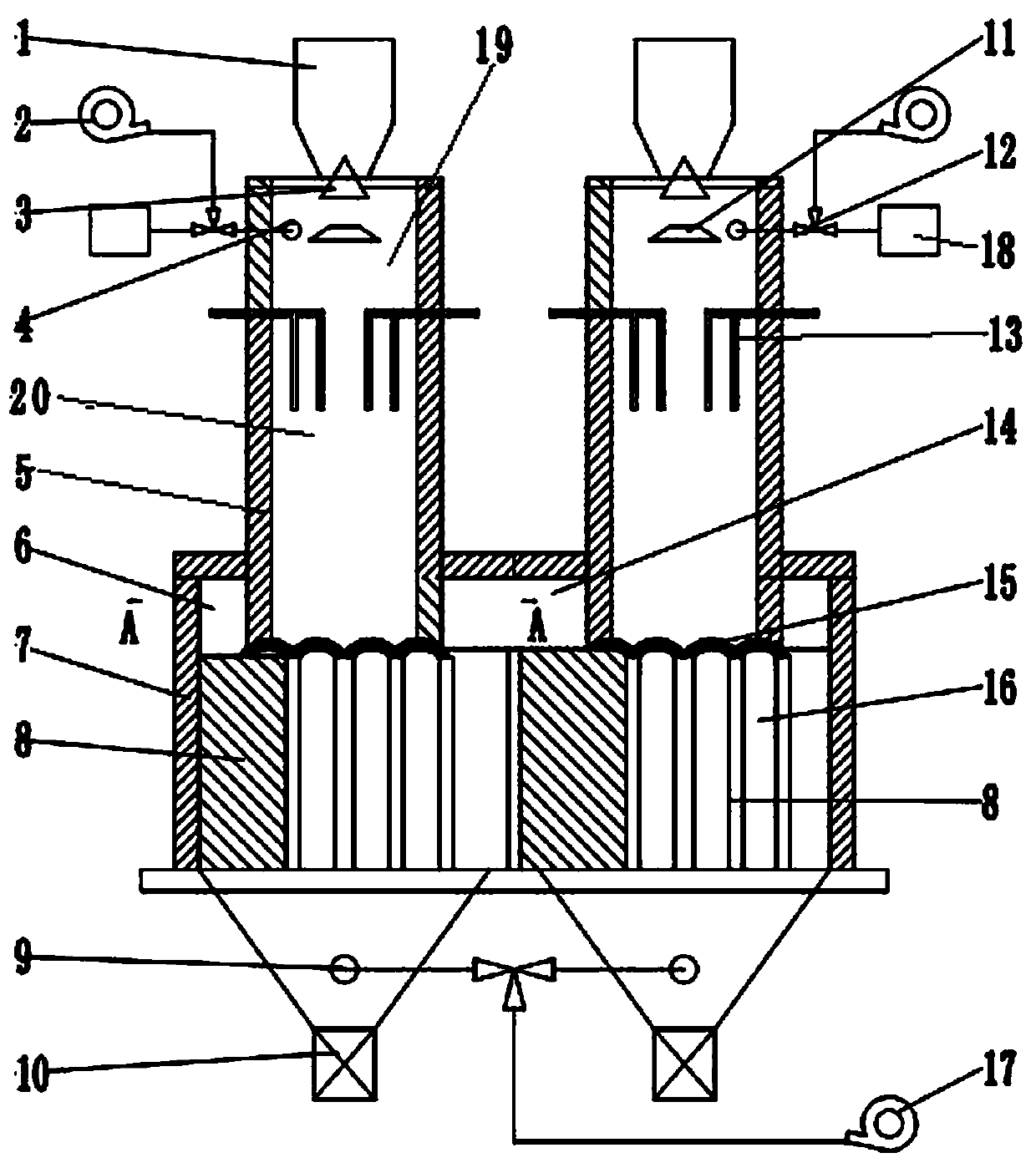

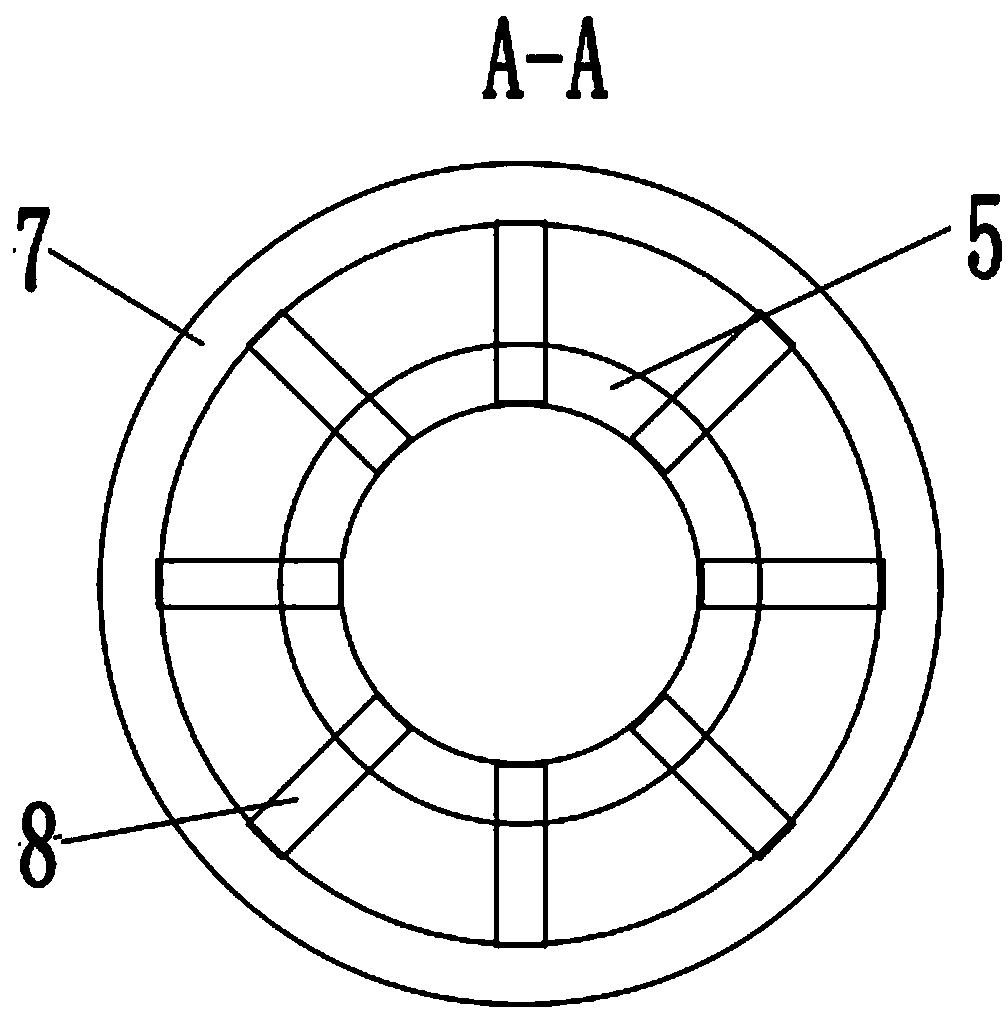

[0014] The hanging cylinder type parallel flow heat storage double chamber kiln of the present invention such as figure 1 As shown, it includes a double chamber kiln body, feeding equipment, discharging equipment, air supply system and exhaust gas discharge system 18. The feeding equipment includes a feeding hopper 1, a feeding lock 3, a distributor 11 and a feeder, and a discharging lock 10 is provided at the discharge port. Exhaust gas emission system includes dust collector, induced draft fan and chimney. The double-chamber kiln body is composed of an upper inner furnace wall 5 and a lower outer furnace wall 7, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com