Preparation method of acrylate emulsion for waterborne printing ink

An acrylate, water-based ink technology, applied in the field of ink, can solve the problems of low stability, poor water resistance, poor anti-adhesion, and achieve the effects of good stability, low water absorption, and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

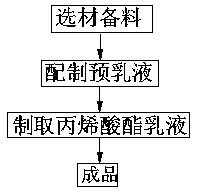

Image

Examples

Embodiment 1

[0015] The specific preparation process of the water-based ink acrylate emulsion mentioned in the present invention is as follows:

[0016] a) Material selection and preparation, the main components of the acrylate emulsion and their ratios are: 3 parts of compound emulsifier, 5 parts of glycidyl methacrylate, 86 parts of mixed monomer, 1 part of acrylic acid, 0.5 part of buffer, initiator 0.6 parts of deionized water and 0.6 parts of deionized water; among them, the composite emulsifier is prepared by mixing non-ionic polymerizable emulsifier ER-30 and anionic polymerizable emulsifier SE-10, and the mass ratio of the two is 2:1; The mixed monomer is obtained by fully mixing 28 parts of methyl methacrylate, 14 parts of styrene and 44 parts of butyl acrylate; the buffer is selected from sodium bicarbonate, and the initiator is selected from ammonium persulfate;

[0017] b) Prepare the pre-emulsion. The preparation process is as follows: First, according to the ratio of parts, d...

Embodiment 2

[0020] The specific preparation process of the water-based ink acrylate emulsion mentioned in the present invention is as follows:

[0021] a) Material selection and preparation, the main components of the acrylate emulsion and their ratios are: 4 parts of compound emulsifier, 6 parts of glycidyl methacrylate, 87 parts of mixed monomer, 2 parts of acrylic acid, 0.6 part of buffer, initiator 0.7 parts of deionized water and 0.7 parts of deionized water; among them, the composite emulsifier is prepared by mixing non-ionic polymerizable emulsifier ER-30 and anionic polymerizable emulsifier SE-10, and the mass ratio of the two is 2:1; The mixed monomer is obtained by fully mixing 28 parts of methyl methacrylate, 14 parts of styrene and 45 parts of butyl acrylate; the buffer is selected from sodium bicarbonate, and the initiator is selected from ammonium persulfate;

[0022] b) Prepare the pre-emulsion. The preparation process is as follows: First, according to the ratio of parts, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com