High-efficiency energy-saving airflow crusher

An airflow pulverizer, high-efficiency and energy-saving technology, applied in the direction of grain processing, etc., can solve the problems of increasing airflow resistance, low critical speed, affecting classification accuracy, etc., and achieve the effect of improving classification accuracy, shortening length, and facilitating implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

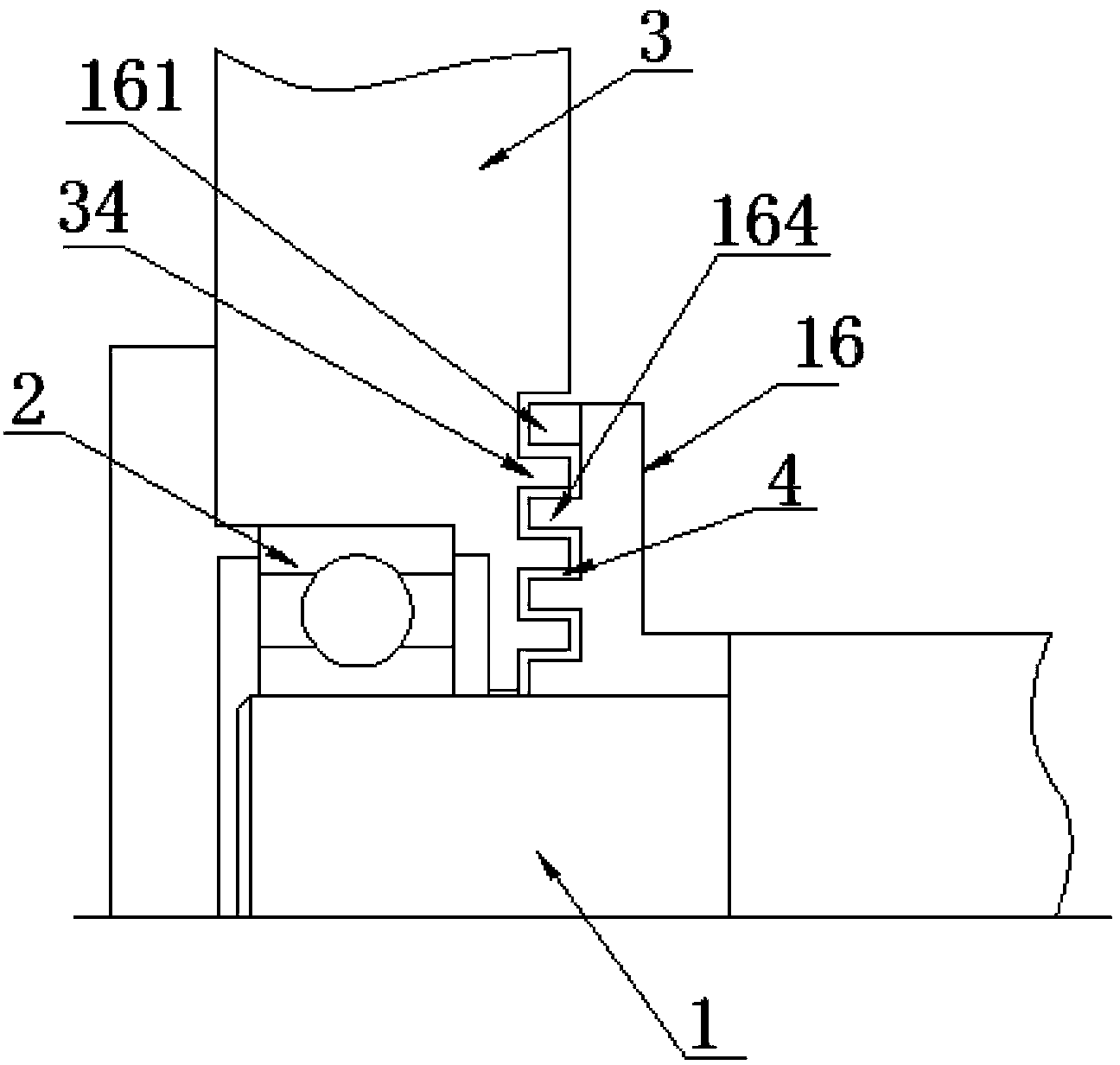

[0048] Embodiment: A high-efficiency and energy-saving jet mill, including a classifying wheel, a rotating shaft, a discharger, a nozzle and a gas distribution plate, also has the following structural features:

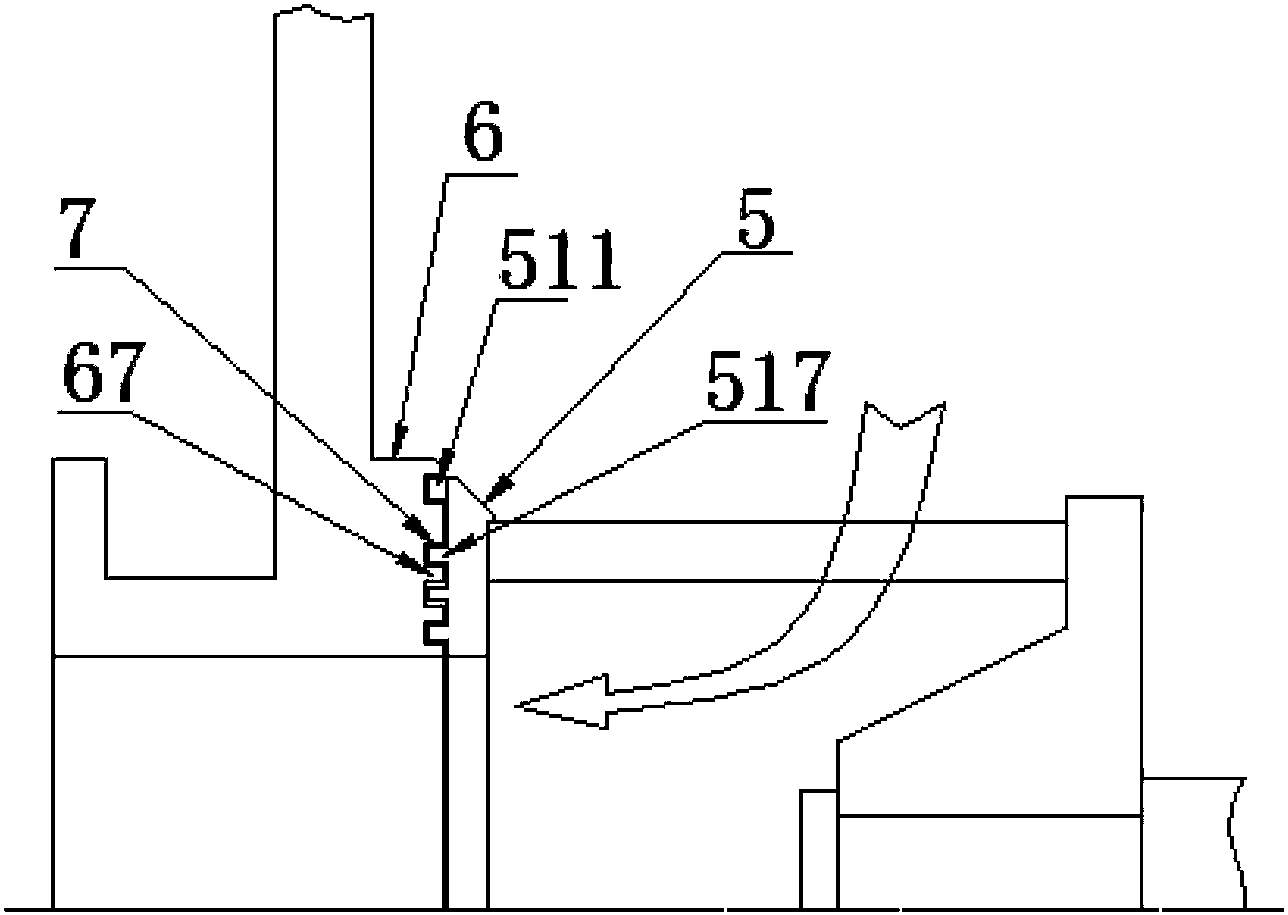

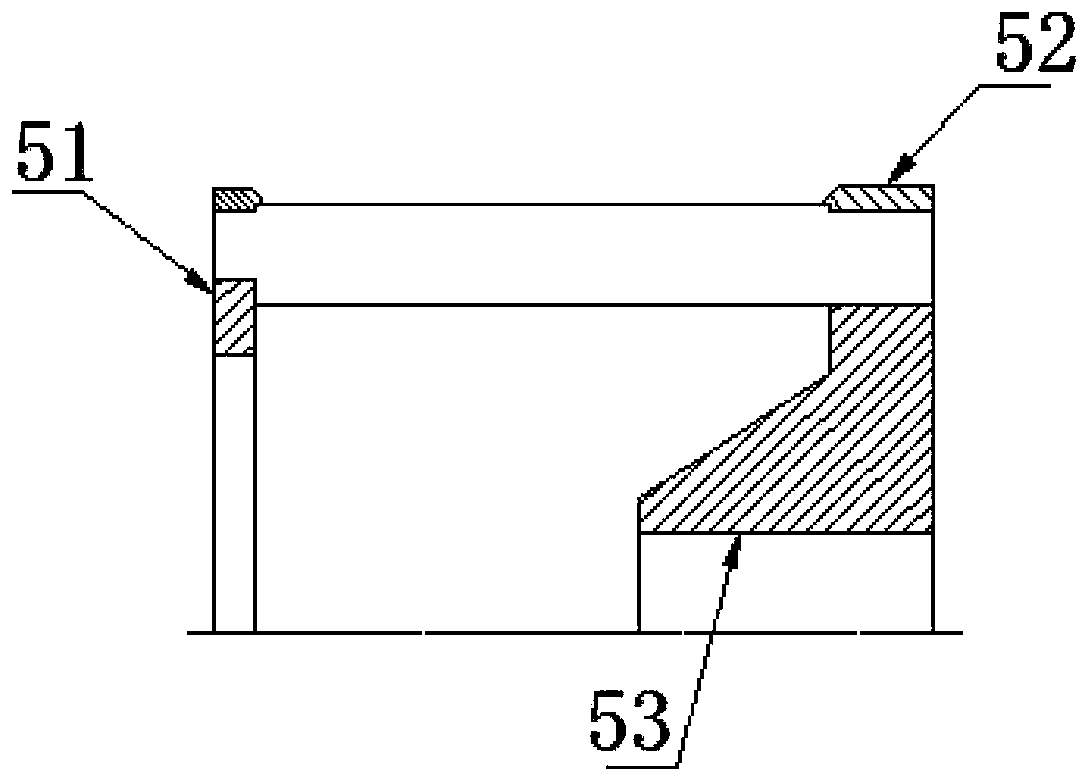

[0049] Such as figure 2 with Figure 8 As shown, the classification wheel 5 is fixedly connected to the rotating shaft 1 at the center, and the front of the classification wheel 5 has a discharge device 6, and the feed end of the discharge device is opposite to the discharge end of the classification wheel. The feed port of the feeder is communicated with the discharge port of the classification wheel, the discharge port 61 of the discharge device is in the same direction as the discharge port of the classification wheel, and the discharge device 6 is connected to the discharge port of the classification wheel. There is a gap between the 5, the first labyrinth seal 7 is provided at the gap between the discharger and the classifying wheel, one end of the rotating sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com