Compound release agent for copper anode casting and preparation method of compound release agent

A release agent and copper anode technology, which is applied in casting molding equipment, molds, mold components, etc., can solve the damage of the release agent, the release agent is not easy to be separated from the white plate rate when the anode plate is quenched by water, and the release agent cannot be formed. Adhesion and other issues to achieve the effect of reducing adhesion, reducing sticking phenomenon, and improving physical specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a preparation method of a composite release agent for copper anode casting, which is characterized in that it comprises the following steps:

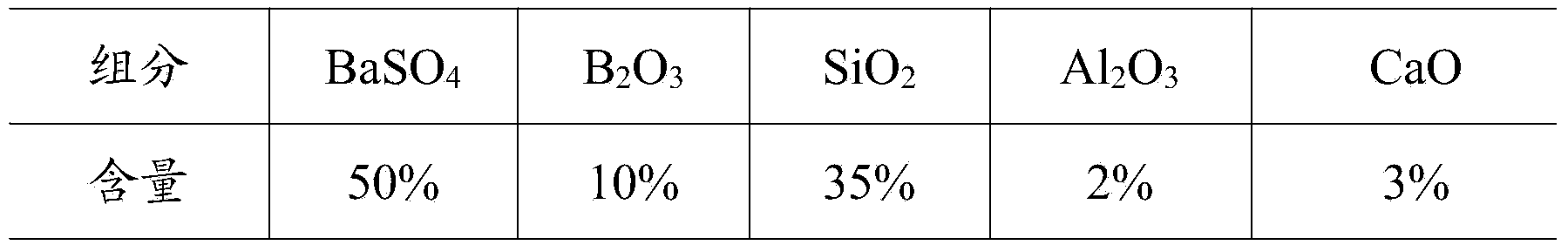

[0041] Prepare the composition of the composite release agent according to the following mass ratio:

[0042] BaSO 4 30%~70%

[0043] B 2 o 3 2.5%~15%

[0044] SiO 2 20%~45%

[0045] Al 2 o 3 1%~7%

[0046] CaO 1%~8%

[0047] where BaSO 4 The particle size is 1000-1200 mesh, B 2 o 3 , SiO 2 、Al 2 o 3 , The particle size of CaO is 150-200 mesh;

[0048] Add it to the mixer and mix it evenly before packing into bags for later use;

[0049] When in use, the prepared powdery composite release agent and water are mixed at a certain temperature to form an emulsion and stirred evenly.

[0050] The temperature is 65-85°C, preferably 80°C.

[0051] The ratio is a liquid-solid ratio of 1.8-2.2:1.

[0052] The present invention will be further described below in conjunction with ex...

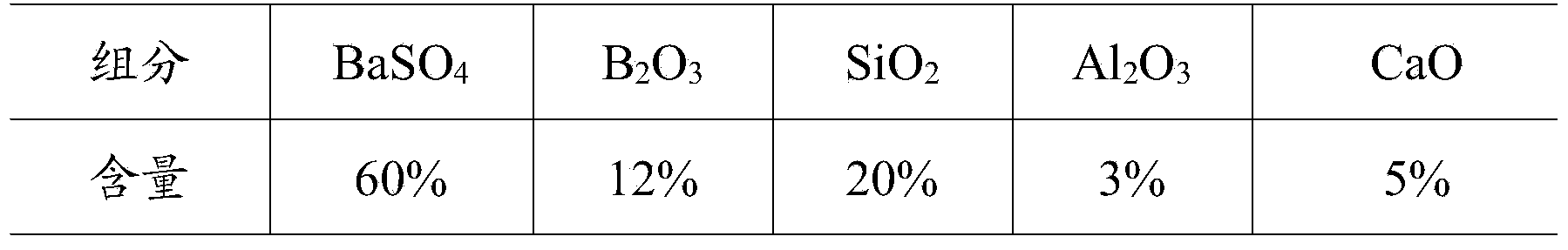

Embodiment 1

[0054] Using the composite release agent composed in Table 1, mix water and release agent according to the mass liquid-solid ratio of 1.8:1, the water temperature is 70°C, stir evenly, control the temperature of the copper mold on the disc casting machine at about 150°C, and then put the prepared A good release agent emulsion is connected to the spraying system to start the normal production order. When the copper mold on the casting machine is transferred to the spraying station of the spraying system, the console controls the direct spraying of the release agent emulsion. Each piece of copper The amount of emulsion sprayed on the mold surface is 2.23kg / m 2. When the copper mold sprayed with release agent arrives at the pouring station, the console controls copper water to pour into the copper mold. The casting temperature of copper water is 1180°C. When copper water is poured on the copper mold covered with release agent, the powder The release agent is sintered to form a s...

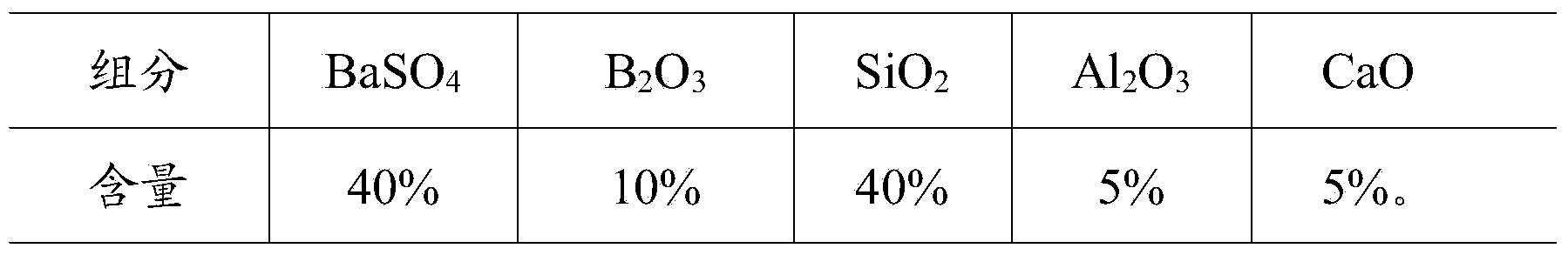

Embodiment 2

[0059] Using the compound release agent composed in Table 2, mix water and release agent according to the mass liquid-solid ratio of 2.2:1, the water temperature is 85°C, stir evenly, control the temperature of the copper mold on the disc casting machine at about 170°C, and then put the prepared A good release agent emulsion is connected to the spraying system to start the normal production order. When the copper mold on the casting machine is transferred to the spraying station of the spraying system, the console controls the direct spraying of the release agent emulsion. Each piece of copper The amount of emulsion sprayed on the mold surface is 1.98kg / m 2 . When the copper mold sprayed with release agent arrives at the pouring station, the console controls copper water to be poured into the copper mold. The casting temperature of copper water is 1240°C. When copper water is poured on the copper mold covered with release agent, the powder The release agent is sintered to for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com