Process for on-line heating and oxidation of desulfurized fly ash by virtue of flue gas from power generating boiler or sintering machine

A power generation boiler, heating and oxidation technology, applied in the direction of calcium/strontium/barium sulfate, energy input, etc., can solve the problems of limited admixture, failure to realize desulfurization ash resource utilization, large-scale utilization, etc., and achieve low operating costs , Change the effects of stockpiling land occupation and polluting water sources, protecting land and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

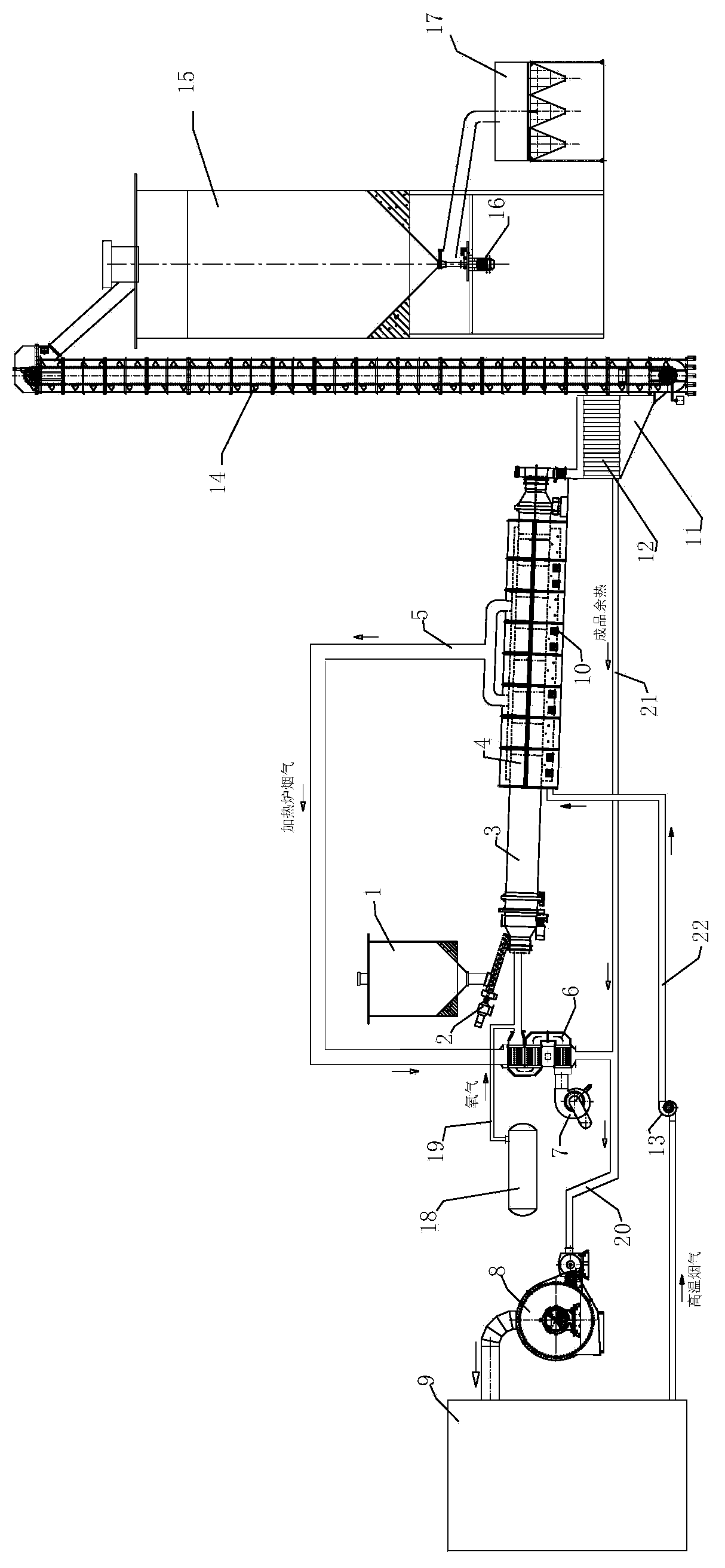

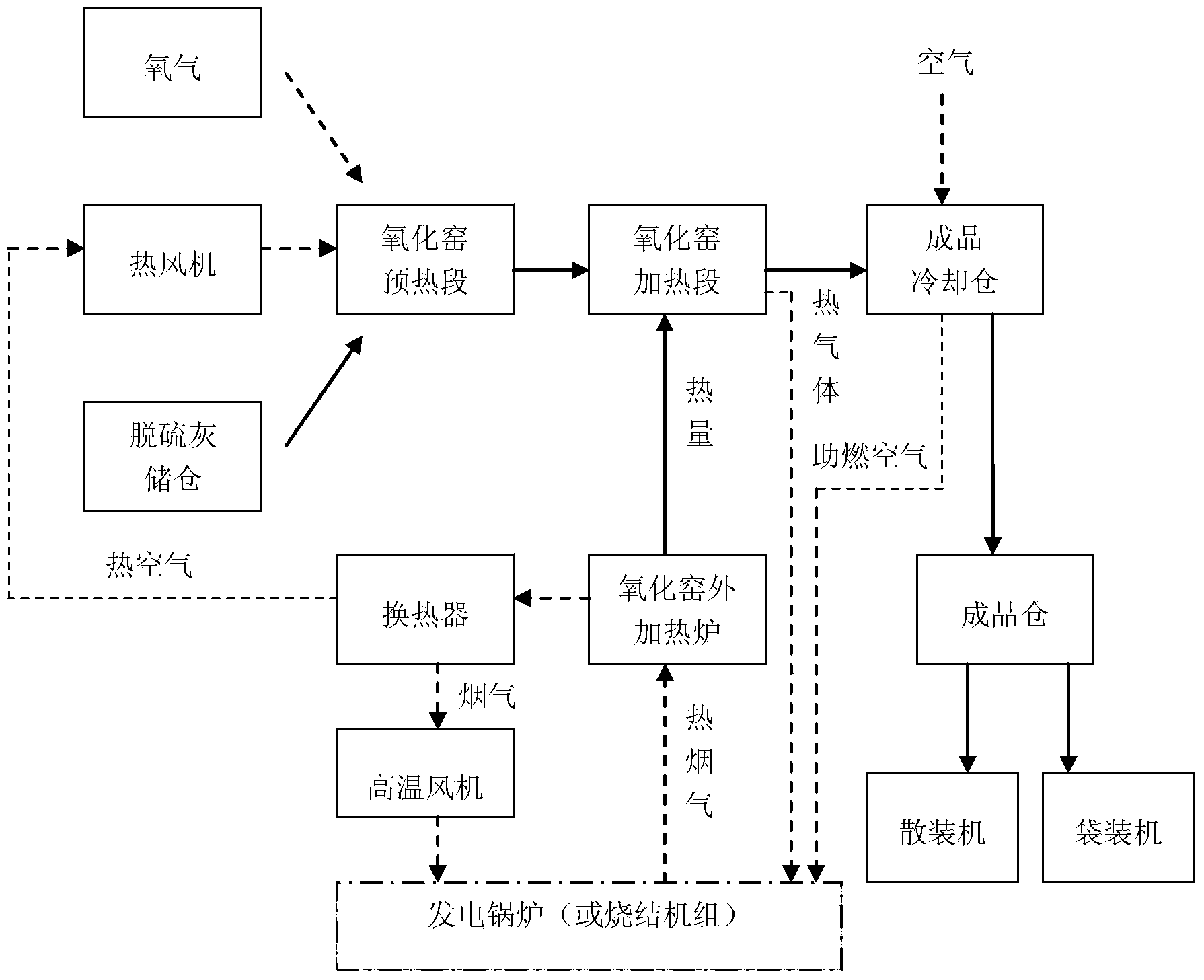

[0028] See figure 1 , is a process flow diagram of the present invention, see figure 2 , is a process flow diagram of the present invention. The present invention uses the flue gas of a power generation boiler or a sintering machine to heat the process of oxidizing and desulfurizing ash on-line, comprising the following steps:

[0029] 1) The 600-800°C high-temperature flue gas produced by the power generation boiler or sintering machine 9 is drawn out by the exhaust fan 13 through the outlet on the flue, and sent into the furnace 10 at the bottom of the heating furnace 4 through the high-temperature flue gas pipeline 22, and is located in the two-stage type The heating section at the rear of the rotary oxidation kiln 3 is externally heated;

[0030] 2) The temperature of the flue gas in the heating furnace 4 is 300°C to 350°C. It is extracted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com