Continuous preparation method of amine-terminated polyether

A technology of amino-terminated polyether and polyether polyol, which is applied in the field of polymer chemistry, can solve the problems of polluting polyether polyol and polyether amine with many side reactions and difficult gasification, and achieve high primary amine selectivity and operation The effect of continuous process and solution to the decline of conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

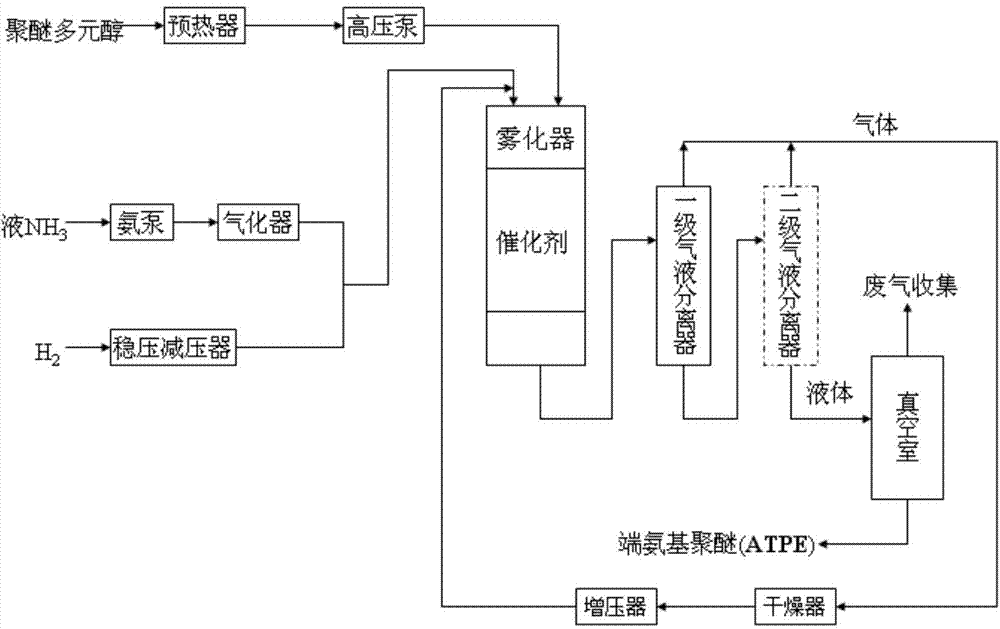

Method used

Image

Examples

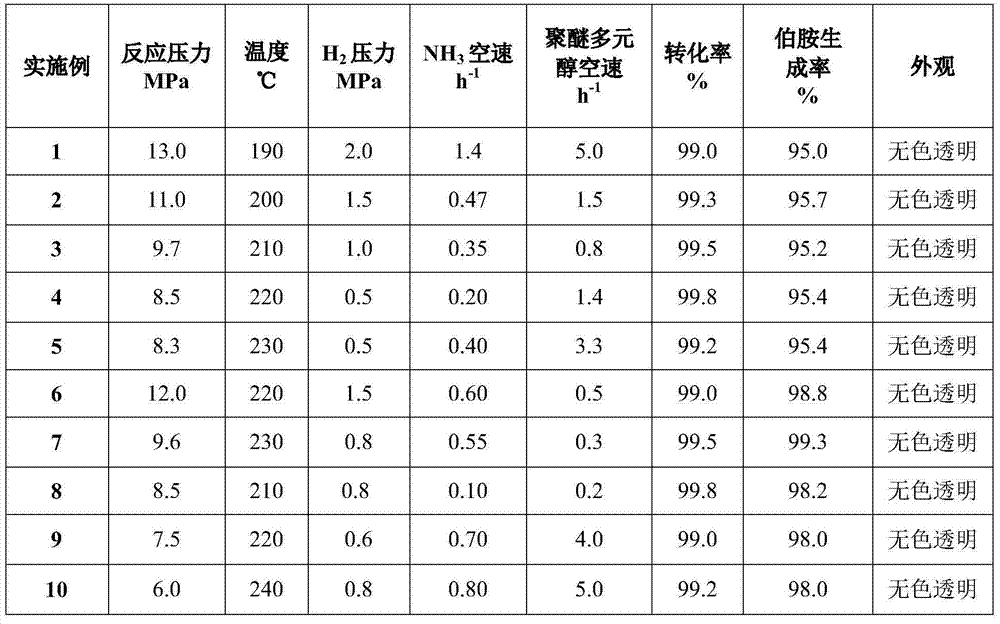

Embodiment 1

[0036] 10mL of hydroamination catalyst (containing Ni 92%, Co 3%, Cr 3%, Mo 2%) was filled in In a fixed-bed reactor (20 mm in diameter, 320 mm in height, and about 100 ml in volume), the raw material polyether polyol is preheated to 50° C. Continuously press 2.0MPa constant pressure H into the reactor at a flow rate of 30L / h 2 , the volume space velocity is 1.4h-1 NH 3 and a volumetric space velocity of 5.0h -1 , molecular weight 230, functionality of 2 raw material polyether polyol (NH 3 The ratio of the number of moles to the number of moles of hydroxyl groups in polyether polyol molecules is 1:1; H 2 The ratio of the number of moles to the number of moles of hydroxyl groups in the polyether polyol molecule is about 3:1); polyether, NH 3 and H 2 After being atomized by the atomizer at the top of the reactor, it contacts with the hydroammination catalyst filled in the middle of the reactor, and the hydroammination reaction occurs at 190°C and 13.0MPa, and the product p...

Embodiment 2

[0039] 30mL of hydroamination catalyst (containing 91% Ni, 4% Co, 3.5% Cr, 1.5% Mo) was filled in the above-mentioned fixed-bed reactor, and the raw material polyether polyol was preheated to 60°C. Continuously press 1.5MPa constant pressure H into the reactor at a flow rate of 25L / h 2 , the volume space velocity is 0.47h -1 NH 3 and a volumetric space velocity of 1.5h -1 , a raw material polyether polyol with a molecular weight of 400 and a functionality of 2 (NH 3 The ratio of the number of moles to the number of moles of hydroxyl groups in polyether polyol molecules is 2:1; H 2 The ratio of the number of moles to the number of moles of hydroxyl groups in the polyether polyol molecule is about 4:1). Polyether, NH 3 and H 2 After being atomized by the atomizer at the top of the reactor, it contacts with the hydroammination catalyst filled in the middle of the reactor, and the hydroammination reaction occurs at 200°C and 11.0MPa, and the product is separated at 130°C by ...

Embodiment 3

[0042] 50mL of hydroamination catalyst (containing Ni 92%, Co 2%, Cr 5%, Mo 1%) was filled in the above-mentioned fixed-bed reactor, and the raw material polyether polyol was preheated to 110°C. Continuously pressurize 1.0MPa constant pressure H into the reactor at a flow rate of 15L / h 2 , the volume space velocity is 0.35h -1 NH 3 and a volumetric space velocity of 0.8h -1 , the molecular weight is 1000, the raw material polyether polyol (NH 3 The ratio of the number of moles to the number of moles of hydroxyl groups in polyether polyol molecules is 7:1; H 2 The ratio of the number of moles to the number of moles of hydroxyl groups in the polyether polyol molecule is about 6:1). Polyether, NH 3 and H 2 After being atomized by the atomizer at the top of the reactor, it contacts with the hydroammination catalyst filled in the middle of the reactor, and the hydroammination reaction occurs at 210°C and 9.7MPa, and the product passes through the primary and secondary gas-liq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com