Cold-resistant type one-step process silane crosslinked polyolefin cable material and preparation method thereof

A cross-linked polyolefin and silane cross-linked technology, which is applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve problems such as sheath cracking, high energy consumption, and troubles for customers, and achieve good low temperature resistance. Simple production process, excellent corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

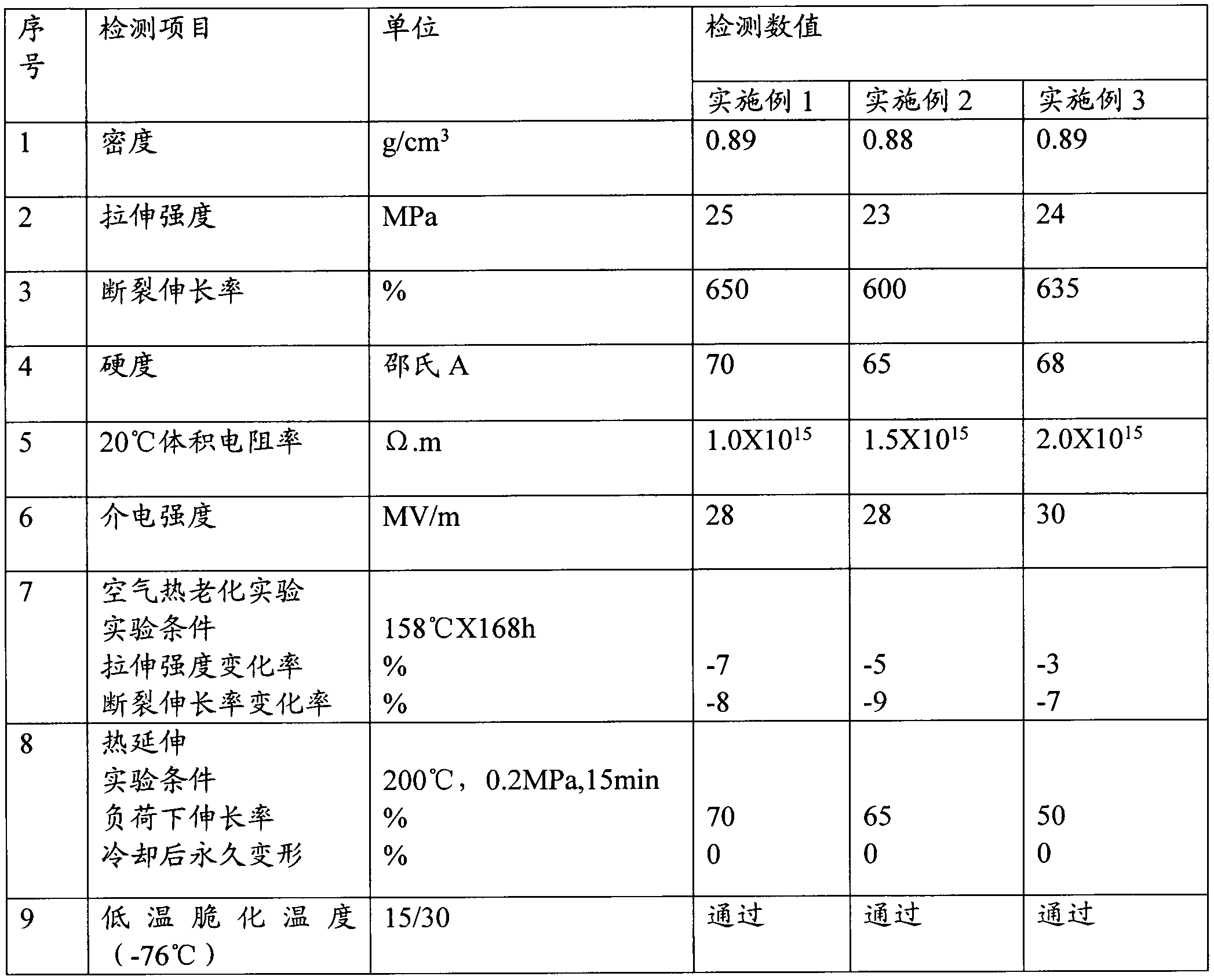

Examples

Embodiment 1

[0047] Cold-resistant one-step silane crosslinked polyolefin cable compound and its preparation method:

[0048] The preparation of a base material

[0049] Weighing: 75 parts of linear low-density polyethylene (LLDPE), 15 parts of ultra-low-density polyethylene (VLDPE), 5 parts of metallocene polyethylene, and 5 parts of polyolefin elastomer are mixed evenly to obtain the base material.

[0050] Preparation of two catalyst master batches

[0051] Weighing: 35 parts of linear low-density polyethylene (LLDPE), 60 parts of ultra-low-density polyethylene (VLDPE), 1 part of antioxidant, 1 part of anti-copper agent, 1 part of catalyst, 2 parts of processing aid, respectively passed double Extrude with a screw extruder, granulate, and dry to obtain the catalyst masterbatch.

[0052] Preparation of trisilane crosslinking mixture

[0053] Weighing: 70 parts of silane crosslinking agent, 1 part of initiator, prepared in a closed stainless steel container, and mixed evenly.

[0054]...

Embodiment 2

[0057] Cold-resistant one-step silane crosslinked polyolefin cable compound and its preparation method:

[0058] The preparation of a base material

[0059] Weighing: 40 parts of linear low-density polyethylene (LLDPE), 30 parts of ultra-low-density polyethylene (VLDPE), 10 parts of metallocene polyethylene, and 20 parts of polyolefin elastomer are mixed evenly to obtain the base material.

[0060] Preparation of two catalyst master batches

[0061] Weighing: 35 parts of linear low-density polyethylene (LLDPE), 60 parts of ultra-low-density polyethylene (VLDPE), 1 part of antioxidant, 1 part of anti-copper agent, 1 part of catalyst, 2 parts of processing aid, respectively passed double Extrude with a screw extruder, granulate, and dry to obtain the catalyst masterbatch.

[0062] Preparation of trisilane crosslinking mixture

[0063] Weighing: 90 parts of silane crosslinking agent, 5 parts of initiator, prepared in a closed stainless steel container, and mixed evenly.

[00...

Embodiment 3

[0067] Cold-resistant one-step silane crosslinked polyolefin cable compound and its preparation method:

[0068] The preparation of a base material

[0069] Weighing: 55 parts of linear low-density polyethylene (LLDPE), 20 parts of ultra-low-density polyethylene (VLDPE), 6 parts of metallocene polyethylene, and 19 parts of polyolefin elastomer were mixed evenly to obtain the base material.

[0070] Preparation of two catalyst master batches

[0071] Weighing: 45 parts of linear low-density polyethylene (LLDPE), 39 parts of ultra-low-density polyethylene (VLDPE), 3 parts of antioxidant, 1 part of anti-copper agent, 2 parts of catalyst, 10 parts of processing aid, respectively passed double Extrude with a screw extruder, granulate, and dry to obtain the catalyst masterbatch.

[0072] Preparation of trisilane crosslinking mixture

[0073] Weighing: 80 parts of silane crosslinking agent, 2 parts of initiator, prepared in a closed stainless steel container, and mixed evenly.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melt flow index | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com