Adhesive film for polarizing plate, polarizing plate and optical display

An adhesive film, polarizing plate technology, applied in the direction of film/sheet adhesive, adhesive type, ester copolymer adhesive, etc., can solve the problems of light leakage of polarizing plate, deterioration of polarizing plate durability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

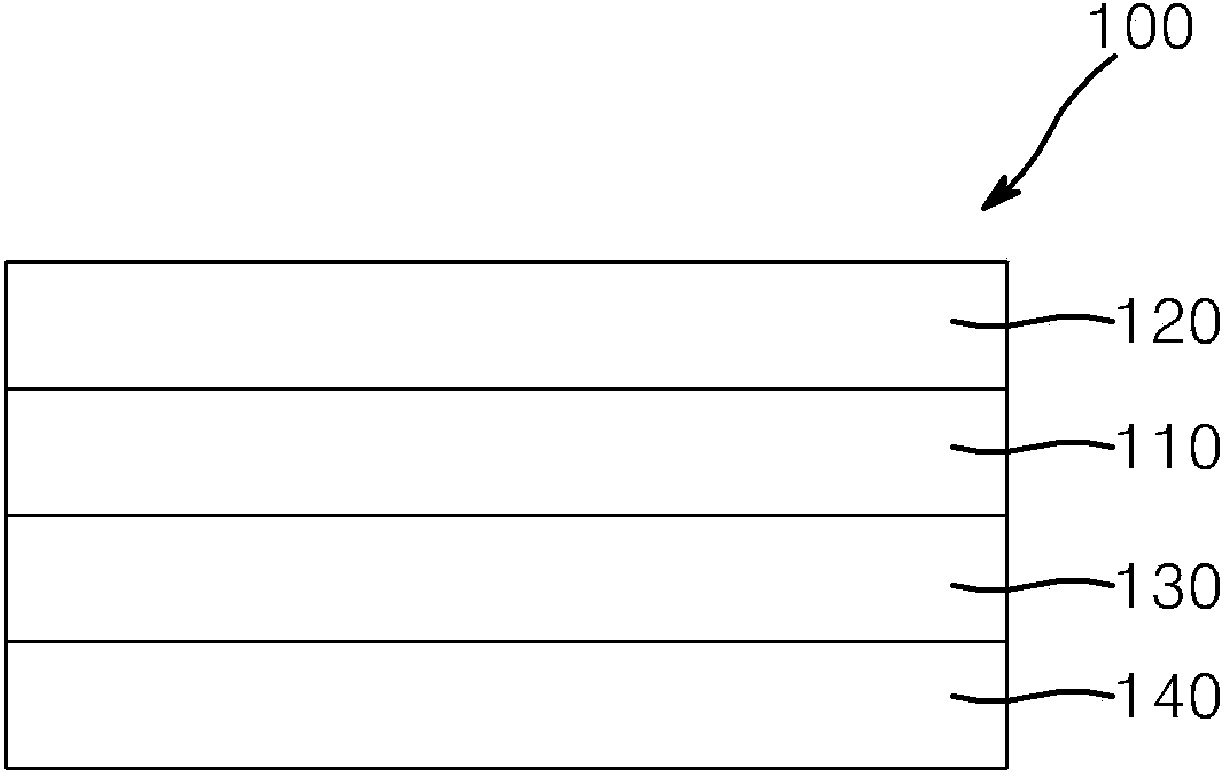

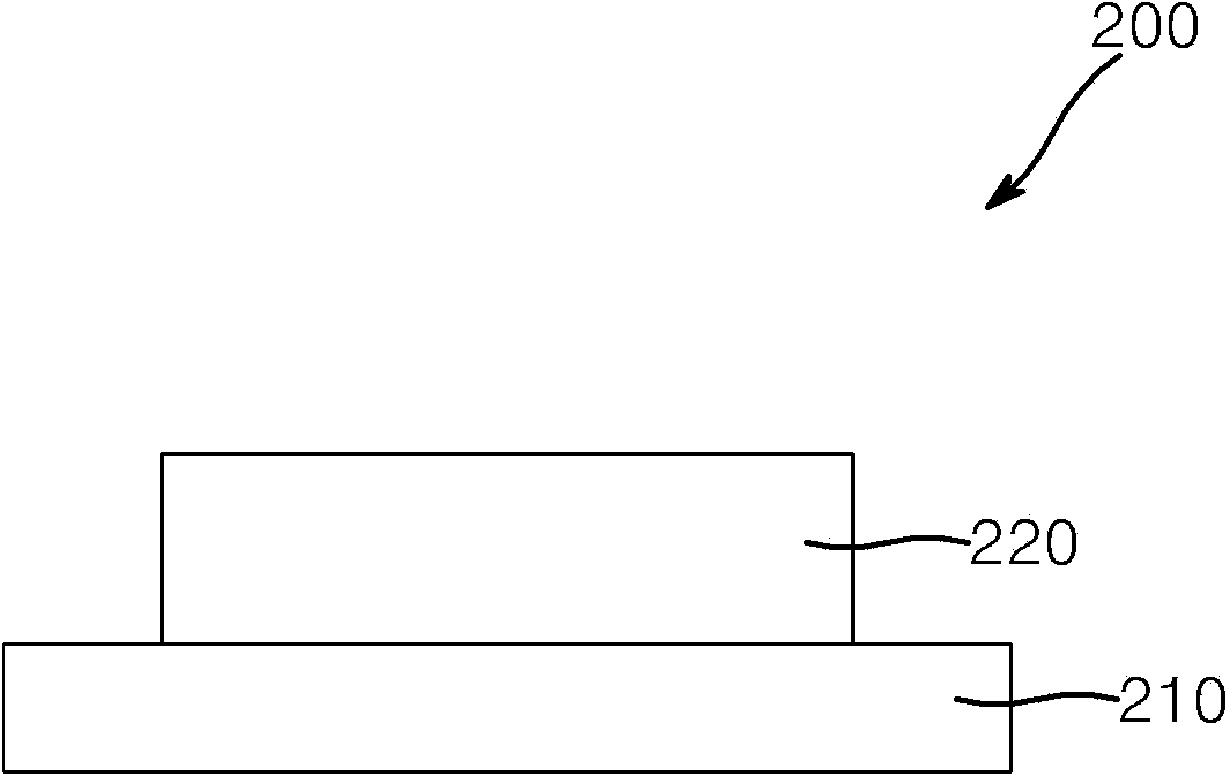

Image

Examples

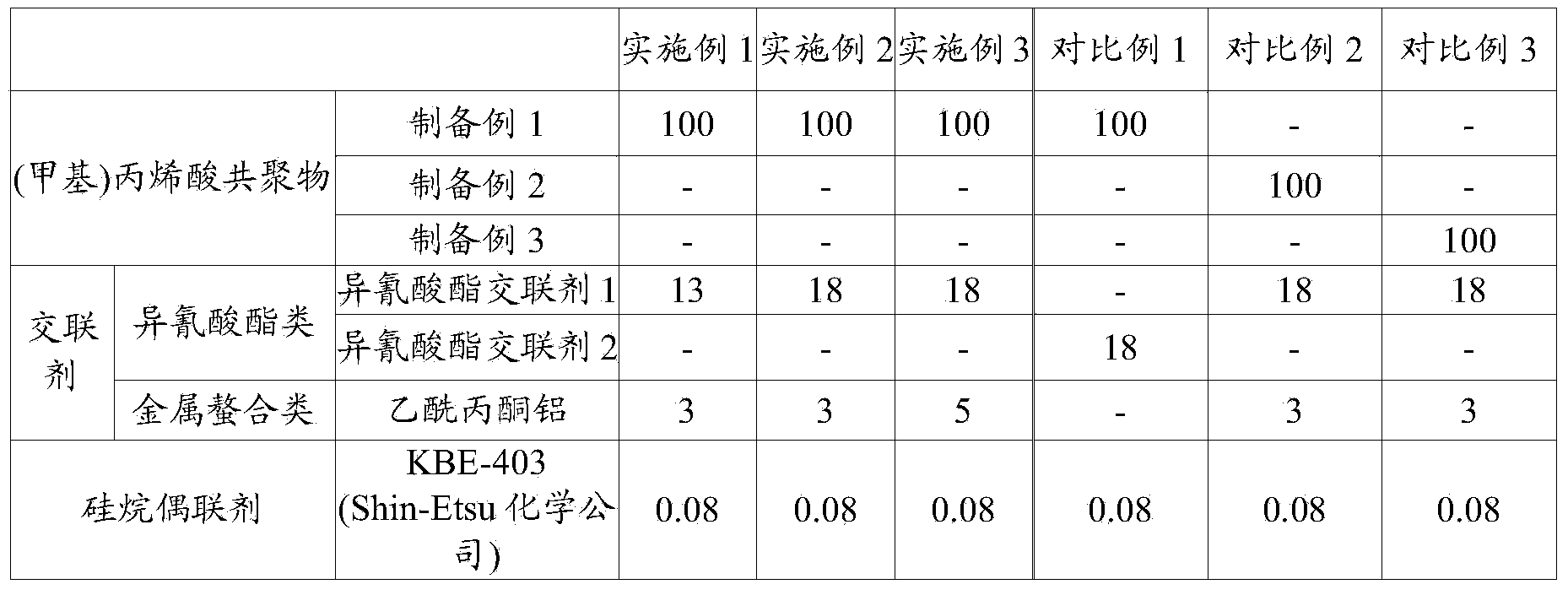

preparation example 1

[0085] In a 1L reactor with a thermometer, a reflux condenser and a stirrer, 97 parts by weight of n-butyl acrylate and a solvent (40 parts by weight of ethyl acetate and 45 parts by weight of methyl ethyl ketone) were placed, followed by heating at 65°C Nitrogen replacement was performed for 30 minutes. Next, 0.06 parts by weight of 2,2'-azobisisobutyronitrile as an initiator was diluted with 2 parts by weight of ethyl acetate, and then added to the reactor. Next, 2 parts by weight of acrylic acid and 1 part by weight of 2-hydroxyethyl methacrylate were dropped into the reactor, followed by reaction for 6 hours while the temperature of the reactor was maintained at 65°C. Next, the reactor was heated to 70° C., thereby performing a reaction for 2 hours. After the reaction was completed, the resulting mixture was diluted with 130 parts by weight of ethyl acetate, thereby obtaining an acrylic copolymer having a weight average molecular weight of 900,000 g / mol.

preparation example 2

[0087]In a 1 L reactor equipped with a thermometer, a reflux condenser, and a stirrer, 97 parts by weight of n-butyl acrylate and 85 parts by weight of ethyl acetate as a solvent were placed, followed by nitrogen substitution at 65° C. for 30 minutes. Next, 0.04 parts by weight of 2,2'-azobisisobutyronitrile as an initiator was diluted with 2 parts by weight of ethyl acetate, and then put into the reactor. Next, 2 parts by weight of acrylic acid and 1 part by weight of 2-hydroxyethyl methacrylate were dropped into the reactor, followed by reaction for 6 hours while the temperature of the reactor was maintained at 65°C. Next, the reactor was heated to 70° C., thereby performing a reaction for 2 hours. After the reaction was completed, the resulting mixture was diluted with 130 parts by weight of ethyl acetate, thereby obtaining an acrylic copolymer having a weight average molecular weight of 1,100,000 g / mol.

preparation example 3

[0089] In a 1L reactor with a thermometer, reflux condenser and stirrer, place 97 parts by weight of n-butyl acrylate, 2 parts by weight of acrylic acid, 1 part by weight of 2-hydroxyethyl methacrylate and 60 parts by weight of ethyl acetate and 25 parts by weight of methyl ethyl ketone as a solvent, followed by nitrogen replacement at 65° C. for 30 minutes. Next, 0.04 parts by weight of 2,2'-azobisisobutyronitrile as an initiator was diluted with 2 parts by weight of ethyl acetate, and then placed in a reactor. Next, the reaction was performed for 6 hours while the temperature of the reactor was maintained at 65° C., and then the reactor was heated to 70° C., thereby performing the reaction for 2 hours. After the reaction was completed, the resulting mixture was diluted with 130 parts by weight of ethyl acetate, thereby obtaining an acrylic copolymer having a weight average molecular weight of 1,000,000 g / mol.

[0090] The retention times of the acrylic copolymers of Prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com