Low-viscosity white oil

A low-viscosity, white oil technology, applied in the field of white oil without carbon deposits, low viscosity and no foam, to achieve the effect of reducing carbon deposits and improving oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The chemical principle and the technology of the preparation method of white oil of the present invention are analyzed below:

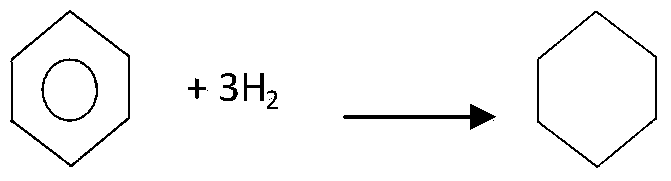

[0017] The hydrogenation reaction removes harmful impurities such as aromatics, sulfur, nitrogen, etc., and the reaction formula is as follows:

[0018] 1 Aromatic saturation

[0019]

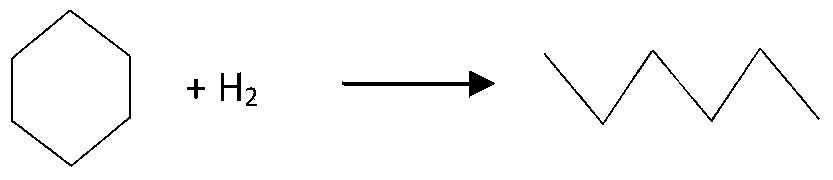

[0020] 2 cycloalkane saturated

[0021]

[0022] 3 nitrogen removal

[0023]

[0024] 4 sulfur removal

[0025]

[0026] After hydrogenation, it is separated by molecular sieves to remove isomeric components. Here is a purely physical process, no chemical reactions are involved. Splitting is to pursue the uniformity of material composition. The split tool is preferably 5A molecular sieve to ensure the quality of the product, and other zeolites with uniform pore size and size around 5A can also be used.

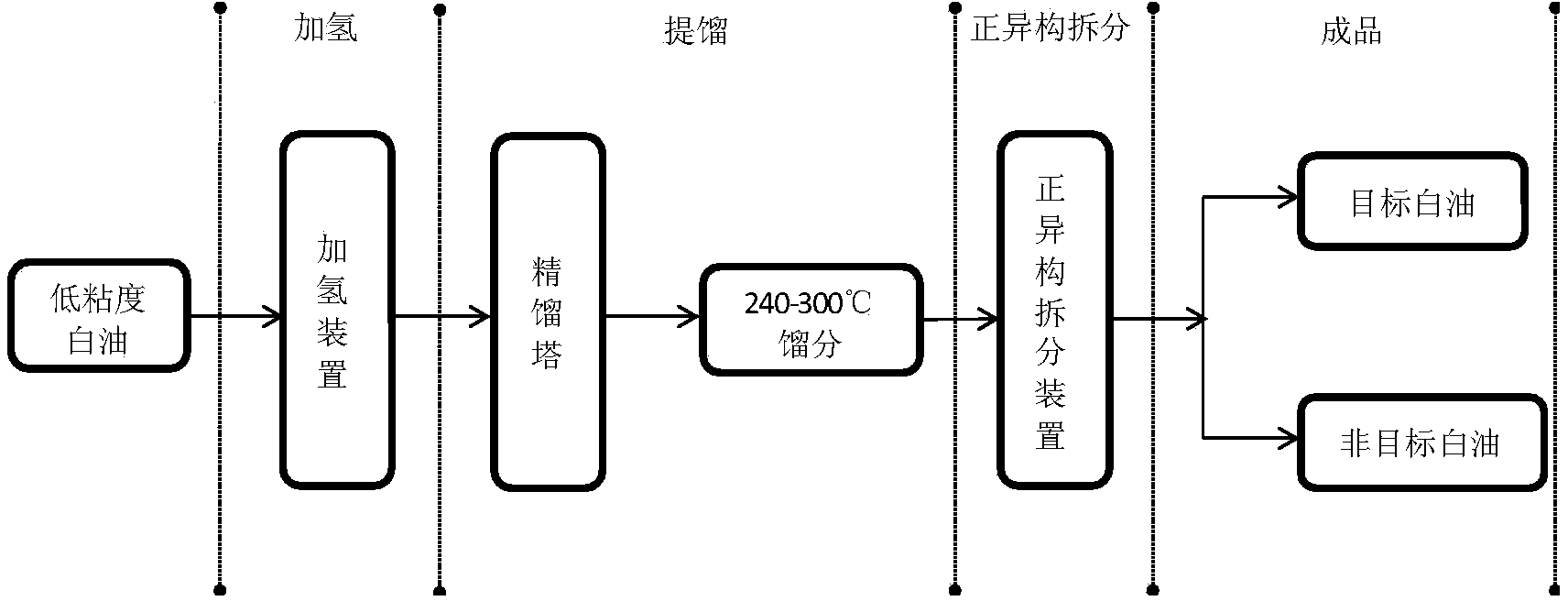

Embodiment 1

[0028] (a) Introduce the low-viscosity white oil into the hydrogenation unit, fully remove aromatics, S, N and other impurities in the white oil after fully reacting at a temperature of 200°C and 16 MPa; (b) pump the hydrogenated white oil Sent to the rectifying tower, the tower top operating pressure of the rectifying tower is normal pressure, and the tower top operating temperature is 240 ℃; Heating in the isomerization resolution device is used to split molecular normal isomers, and the separated target white oil is obtained at the top of the normal isomerization resolution device.

[0029] Described target white oil comprises following alkane component, is by weight percentage: C 13 and C 16 10%, C 14 80%, C 15 10%.

[0030] The normal mass content in the target white oil is ≥80%, and the product density is 0.770-0.780. The foam test shows that the foam disappears in less than 2 seconds, and there is no carbon deposit after burning for 48 hours.

Embodiment 2

[0032] (a) Introduce the low-viscosity white oil into the hydrogenation unit, fully remove the aromatics, S, N and other impurities in the white oil after fully reacting at a temperature of 210°C and 17MPa; (b) pump the hydrogenated white oil Sent to the rectifying tower, the tower top operating pressure of the rectifying tower is normal pressure, and the tower top operating temperature is 300 ℃; Heating in the isomerization resolution device is used to split molecular normal isomers, and the separated target white oil is obtained at the top of the normal isomerization resolution device.

[0033] Described target white oil comprises following alkane component, is by weight percentage: C 13 and C 16 5%, C 14 80%, C 15 15%.

[0034] The normal structure weight content in the target white oil is more than 85%, the product density is 0.770-0.780, the foam test is carried out, the foam disappears in less than 2 seconds, and there is no carbon deposit after burning for 48 hours....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com