Method for producing whiskey using waste yeast from beer production

A production process and a technology for discarding yeast, applied in the technical field of distilled wine, can solve the problems of high yield, unsatisfactory sensory evaluation, and reduced output, and achieve the effects of simple operation, crystal clear color, and dry taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

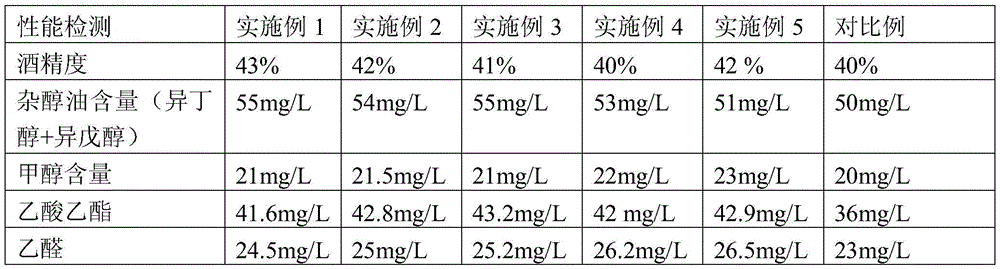

Examples

Embodiment 1

[0041] A method for producing whiskey with waste yeast in the beer production process, comprising the following steps:

[0042] (1) Collection and treatment of waste beer yeast sludge:

[0043] Collect the yeast sludge produced in the beer fermentation process from the beer with an alcohol content above 4%, use a small beer fermentation tank as a temporary storage tank, and directly connect the bottom valve with the bottom valve of the temporary storage tank when the fermentation tank discharges yeast, before operation Connecting pipes, staging tanks, and valves should be sterilized. To prevent the contamination of miscellaneous bacteria, miscellaneous bacteria will increase the bad flavor in beer. The collected yeast sludge is put into a temporary storage tank at 3°C for temporary storage. The collected yeast sludge is filtered through a cross-flow filter to remove waste yeast. Cross-flow The filter element of the filter has a filter diameter of 0.6-0.9 μm and a filtration a...

Embodiment 2

[0048] A method for producing whiskey with waste yeast in the beer production process, comprising the following steps:

[0049] (1) Collection and treatment of waste beer yeast sludge:

[0050] Collect the yeast sludge produced in the beer fermentation process from the beer fermented below 5% alcohol content, use a small beer fermentation tank as a temporary storage tank, and directly connect the bottom valve with the bottom valve of the temporary storage tank when the fermentation tank discharges yeast, before operation Connecting pipes, staging tanks, and valves should be sterilized. To prevent the contamination of miscellaneous bacteria, miscellaneous bacteria will increase the bad flavor in the beer. The collected yeast sludge is put into a temporary storage tank at 5°C for temporary storage. The collected yeast sludge is filtered by a centrifugal filter to remove yeast. The rotational speed of the centrifugal filter It is 3000r / min, and the centrifugation time is 15min, ...

Embodiment 3

[0056] A method for producing whiskey with waste yeast in the beer production process as described in Example 1, the difference is:

[0057] In step (3), the semi-finished product obtained in step (2) is aged with deep-roasted oak chips: take deep-roasted oak chips and put them into a stainless steel fermenter to seal. The dosage is: add 1 g of deep-roasted oak chips per liter of whiskey, Aging time of 2 months at 13°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com