Internal power pneumatic automatically-intermittent circulator

A pneumatic, internal power technology, applied in the direction of gas production bioreactors, biochemical instruments, biochemical equipment and methods, etc., can solve the problems of long production cycle, high production energy consumption, poor comprehensive benefits, etc., to reduce power The effect of consumption, shortening production cycle and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

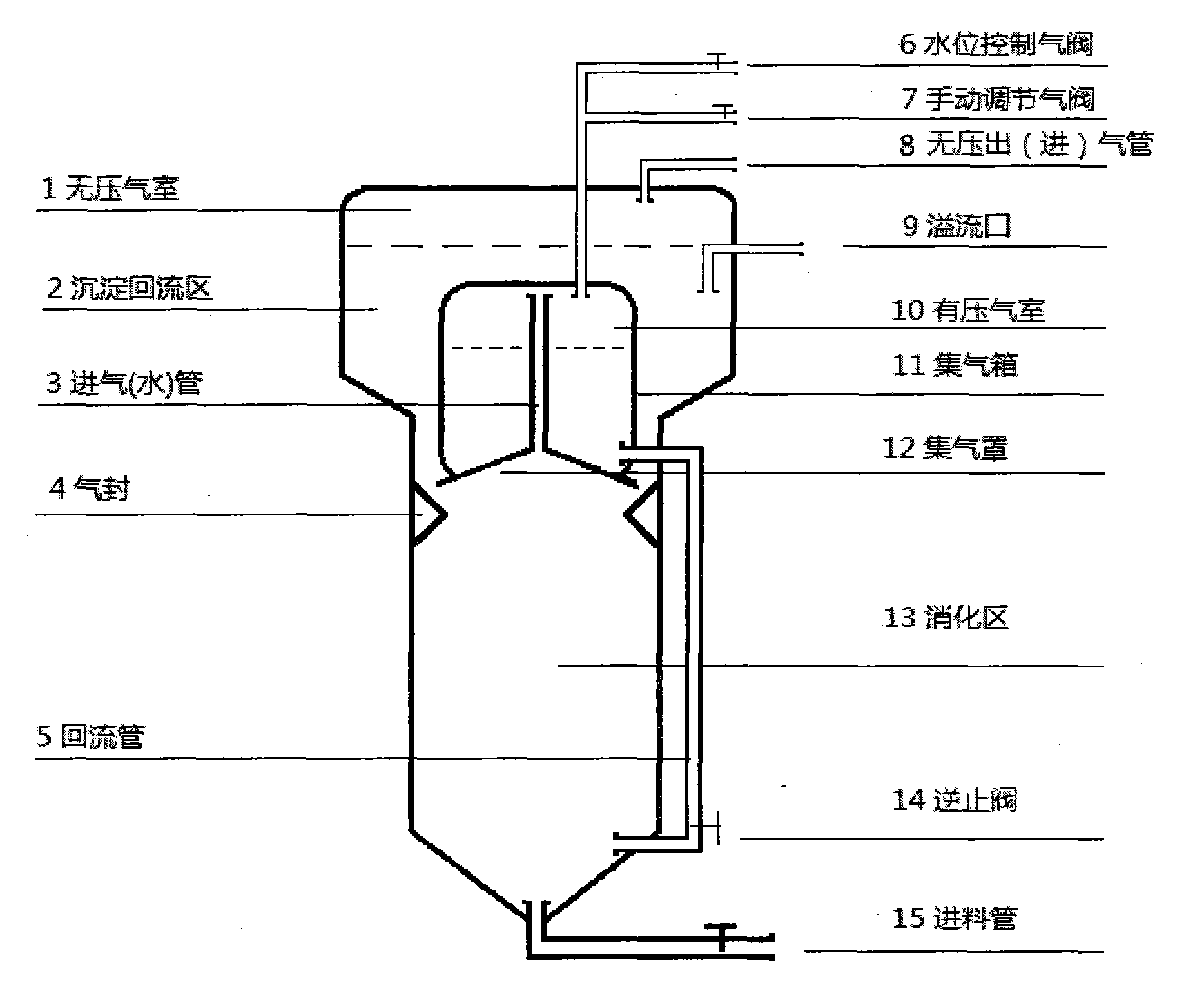

[0007] In the figure, the digestion zone 13 continuously produces biogas, and the biogas enters the gas collection box 11 continuously through the gas seal 4 and the gas collection hood 11 through the intake (water) pipe 3. At this time, the water level control gas installed on the top of the gas collection box 11 The valve 6 is in the closed state, and the pressure in the gas collection box 11 is constantly increasing to force the feed liquid to be continuously pressed into the bottom of the digestion zone 13 by the gas through the return pipe 5 and the check valve 14 installed at the bottom of the gas collection box 11. When the water level in the gas box 11 is pressed to the set low water level by the gas, the water level control valve 6 is automatically opened, and the gas in the gas collection box 11 is continuously discharged, because the water level in the sediment return area 2 is higher than that of the gas collection box 11 Yes, at this time, the feed liquid in the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com