Furnace roller surface anti-dross device of strip steel annealing furnace

An annealing furnace and anti-nodulation technology, used in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of increasing the consumption of spare parts, increasing the number of furnace openings, and replacing furnace rollers with high labor intensity, so as to improve the product yield and The effect of the unit operation rate, the reduction of spare parts costs and production costs, and the reduction of the number of roll changes in the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the embodiments.

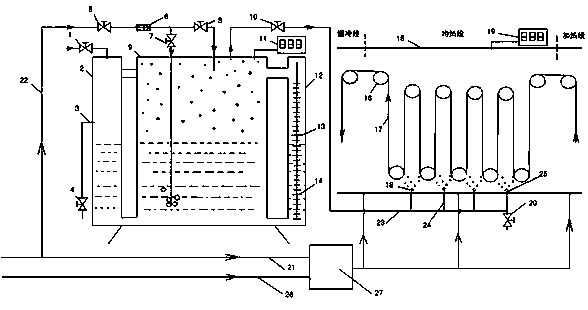

[0013] Depend on figure 1 It can be seen that an anti-nodulation device for the furnace roll surface of a strip steel annealing furnace comprises an annealing furnace 15, a furnace roll 16 is arranged in the annealing furnace, a furnace room dew point indicator 19 is arranged outside the top of the soaking section of the annealing furnace, and a nitrogen delivery pipe 21. The hydrogen delivery pipe 26 is respectively connected to the gas source and the gas mixing station 27, the gas mixing station supplies gas to the annealing furnace, the nitrogen delivery pipe is provided with an air intake pipeline 22, and the outlet end of the air intake pipeline is controlled by a nitrogen inlet valve 5, decompression Valve 6, moisture regulating valve 7, and dry gas regulating valve 8 are connected to the nitrogen humidification device, and the nitrogen humidification device is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com