Reactive printing method of polyester imitation silk fabric

A reactive printing, imitating silk technology, applied in the direction of dyeing, plant fiber, textile and paper making, etc., to achieve the effect of low enzyme treatment temperature, improved utilization rate and less energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) fabric enzyme pretreatment: put the polyester-cotton imitation silk fabric fabric after the degumming tenter into the enzyme solution for pretreatment;

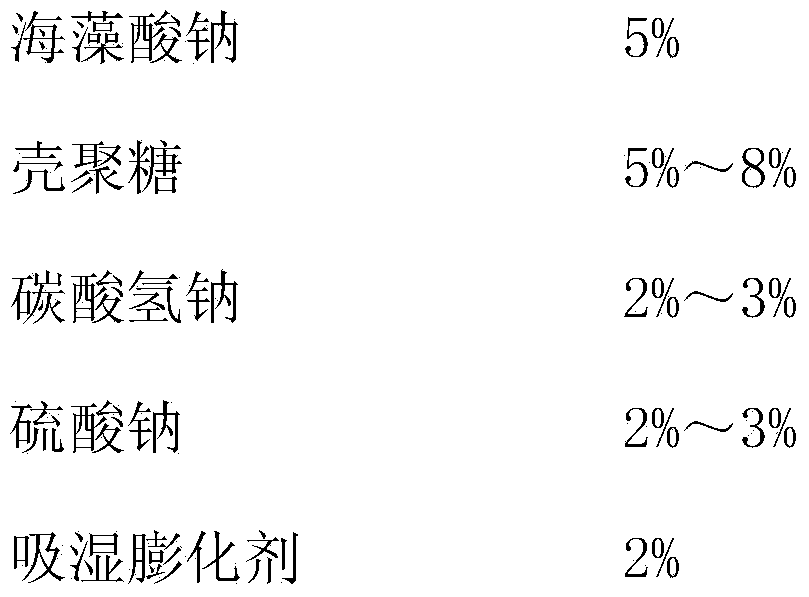

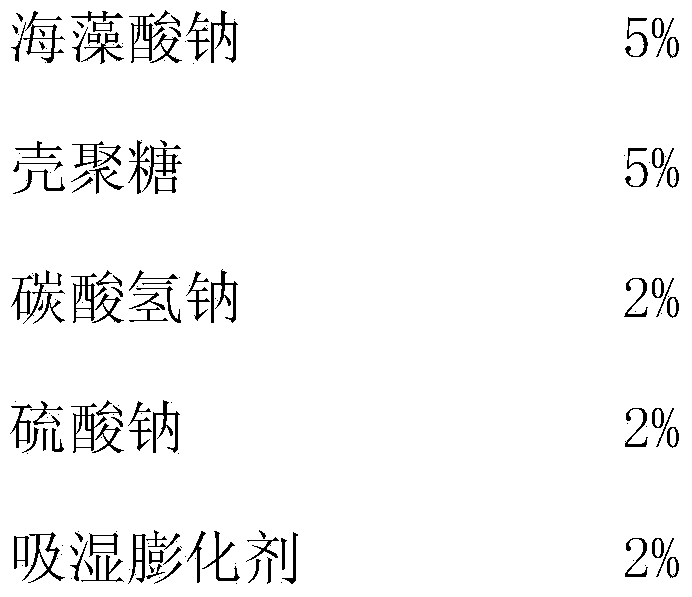

[0032] (2) Sizing: The polyester-cotton silk-like fabric after enzyme pretreatment is sizing on a sizing machine for one side,

[0033] (3) Drying: Infrared drying equipment is used, the drying temperature is 120°C, and the drying time is 5 minutes;

[0034] (4) Making documents: the jet printing is generated by the color card software, the printing conditions are: printing accuracy 360×2160dpi, 360×21606passCMYK, the ink used for jet printing is regenerative reactive dye ink;

[0035] (5) Jet printing: D-2200 digital inkjet printing machine for jet printing;

[0036] (6) steam drying;

[0037] (7) Water washing: after cold water washing, soaping is carried out, and cold water washing is carried out again, and described soaping is 20min under the condition of 120 ℃, and soaping agent is modified tea saponin 2~10g...

Embodiment 2

[0053] (1) fabric enzyme pretreatment: put the polyester-cotton imitation silk fabric fabric after the degumming tenter into the enzyme solution for pretreatment;

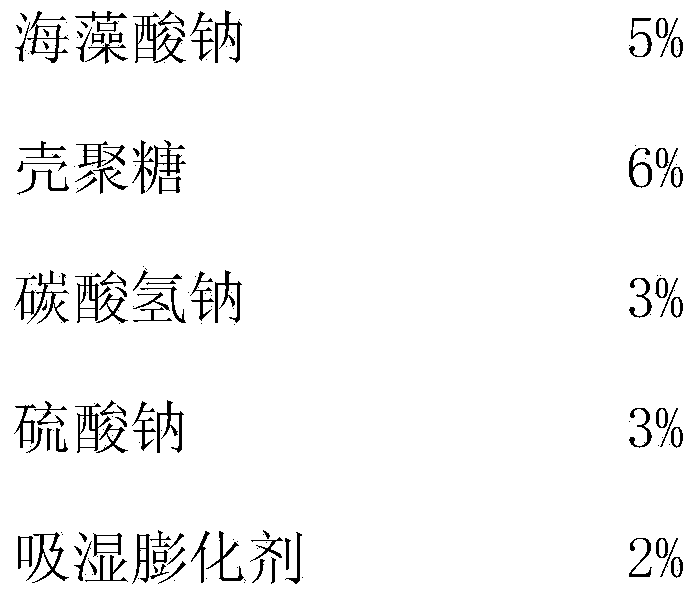

[0054] (2) Sizing: The polyester-cotton silk-like fabric after enzyme pretreatment is sizing on a sizing machine for one side,

[0055] (3) Drying: Infrared drying equipment is used, the drying temperature is 120°C, and the drying time is 5 minutes;

[0056] (4) Making documents: the jet printing is generated by the color card software, the printing conditions are: printing accuracy 360×2160dpi, 360×21606passCMYK, the ink used for jet printing is regenerative reactive dye ink;

[0057] (5) Jet printing: D-2200 digital inkjet printing machine for jet printing;

[0058] (6) steam drying;

[0059] (7) Water washing: after cold water washing, soaping is carried out, and cold water washing is carried out again, and described soaping is 20min under the condition of 120 ℃, and soaping agent is modified tea saponin 2~10g...

Embodiment 3

[0075] (1) fabric enzyme pretreatment: put the polyester-cotton imitation silk fabric fabric after the degumming tenter into the enzyme solution for pretreatment;

[0076] (2) Sizing: The polyester-cotton silk-like fabric after enzyme pretreatment is sizing on a sizing machine for one side,

[0077] (3) Drying: Infrared drying equipment is used, the drying temperature is 120°C, and the drying time is 5 minutes;

[0078] (4) Making documents: the jet printing is generated by the color card software, the printing conditions are: printing accuracy 360×2160dpi, 360×21606passCMYK, the ink used for jet printing is regenerative reactive dye ink;

[0079] (5) Jet printing: D-2200 digital inkjet printing machine for jet printing;

[0080] (6) steam drying;

[0081] (7) Water washing: after cold water washing, soaping is carried out, and cold water washing is carried out again, and described soaping is 20min under the condition of 120 ℃, and soaping agent is modified tea saponin 2~10g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com