Suspension accommodating type freeze drying device

A containment, freeze-drying technology, applied in drying, transportation and packaging, drying solid materials, etc., can solve the problems of enzymes, drug inactivation, product damage, dust generation, etc., to shorten production time, reduce dust generation, The effect of increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific embodiments adopted by the present invention will be further described by the following embodiments and attached drawings.

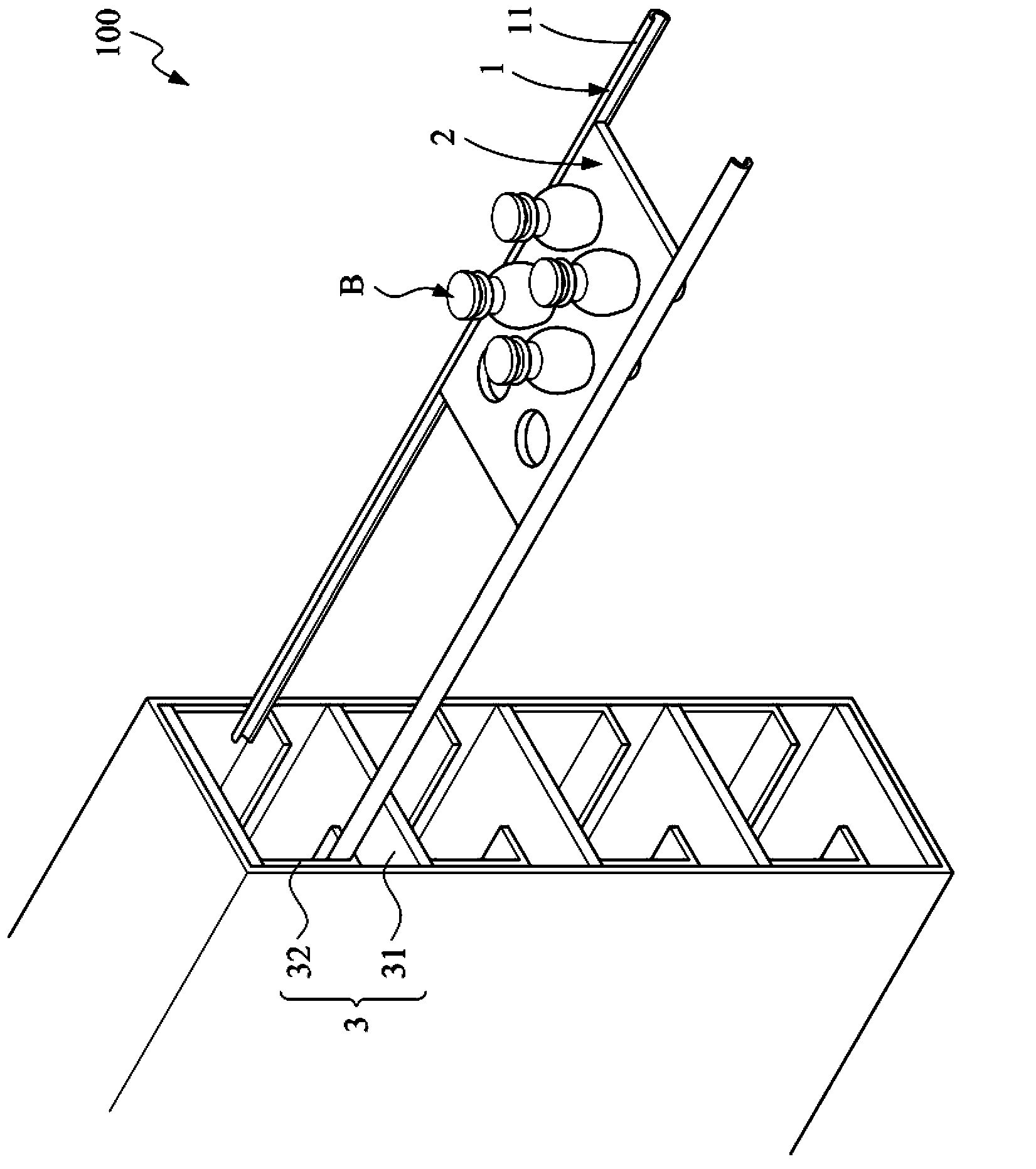

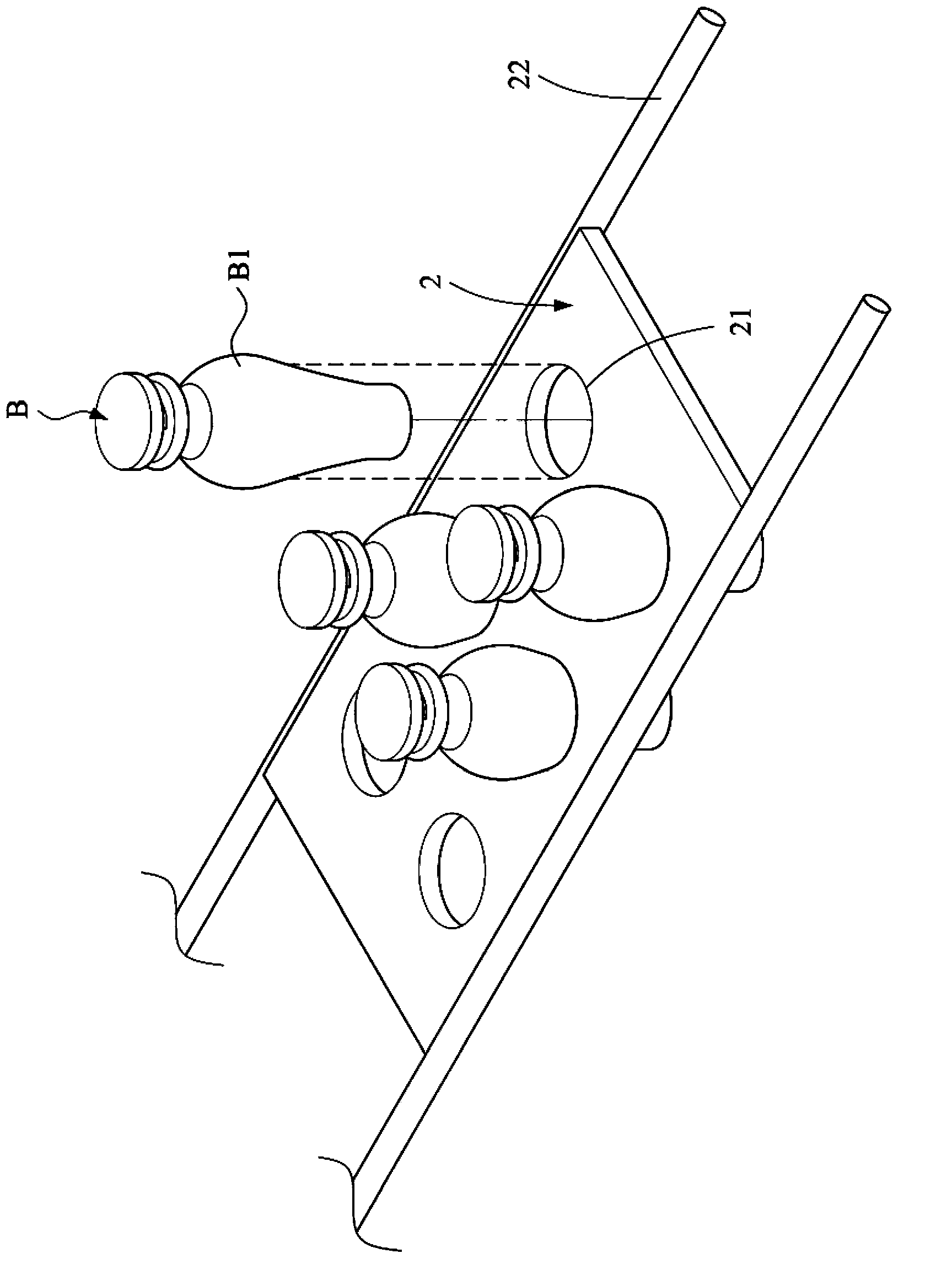

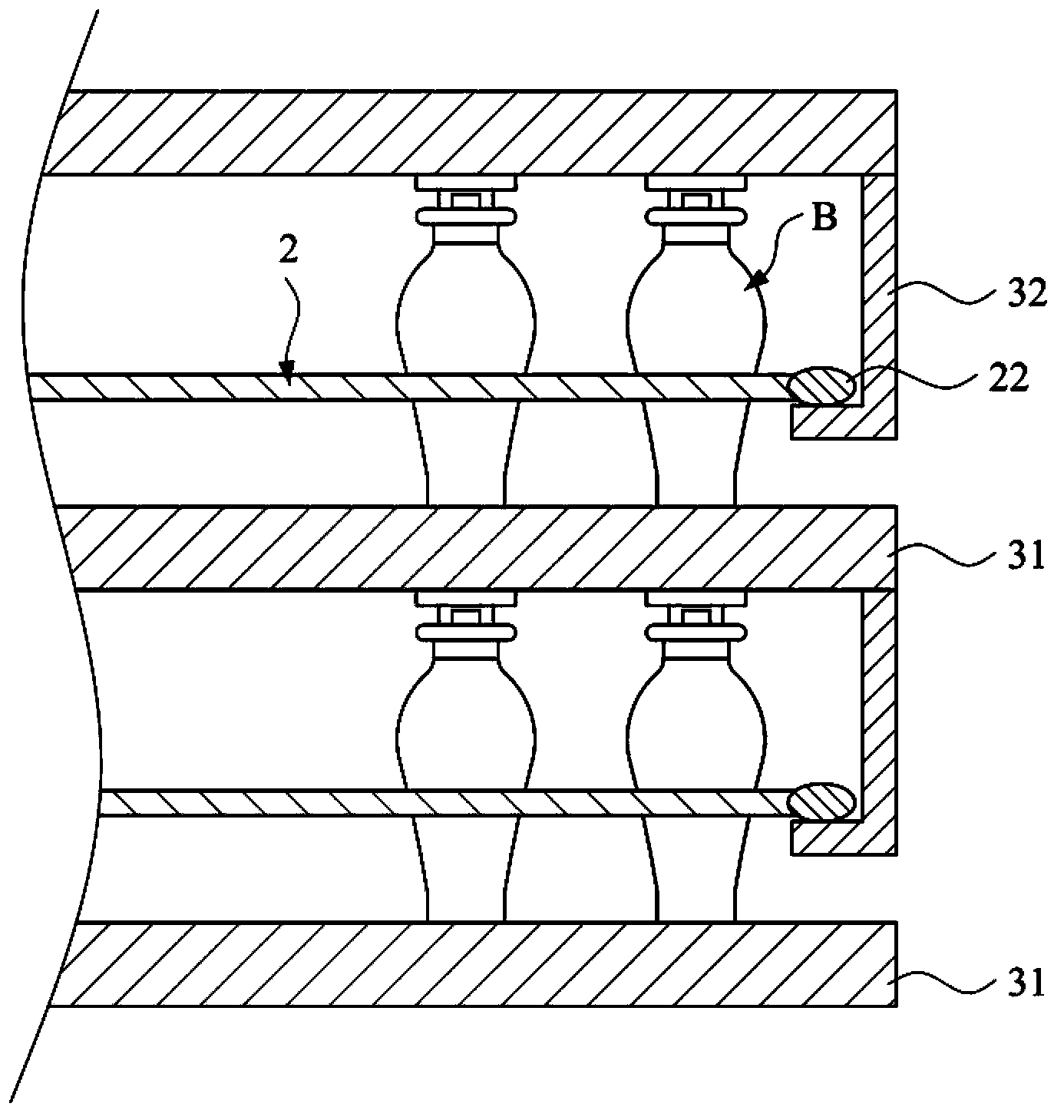

[0044] see Figure 1 to Figure 5 , according to the first embodiment of the present invention, a hanging and accommodating freeze-drying device 100 includes: a transmission and conveying mechanism 1 , a clamping member 2 , a plurality of stacking mechanisms 3 , and a stacking transmission mechanism 4 .

[0045] The transmission conveying mechanism 1 has a slide rail member 11 and a transmission conveying motor (not shown in the figure) for conveying the clamping member 2 . The track surface of the slide member 11 can be paved with quartz or other hard powder materials, which are less likely to generate dust during transportation. Preferably, the transmission and conveying motor is an AC servo motor, which has less vibration during operation, which can make dust less likely to be generated when the member 2 is clamped during conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com