Method of utilizing Tenax as simulant with GCMS (Gas Chromatography Mass Spectrometry) to determine transfer volume of aromatic amine in paper and paperboard

A technology of aromatic amines and migration, applied in the direction of measuring devices, instruments, scientific instruments, etc., to achieve the effect of accurate method, good recovery rate and feasible method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

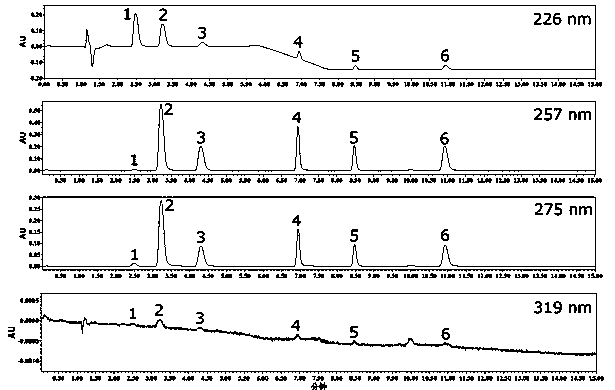

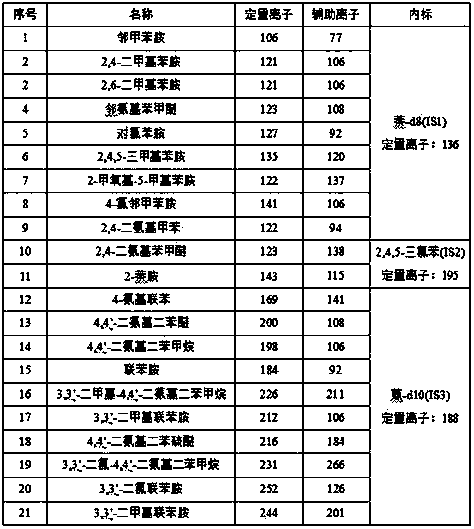

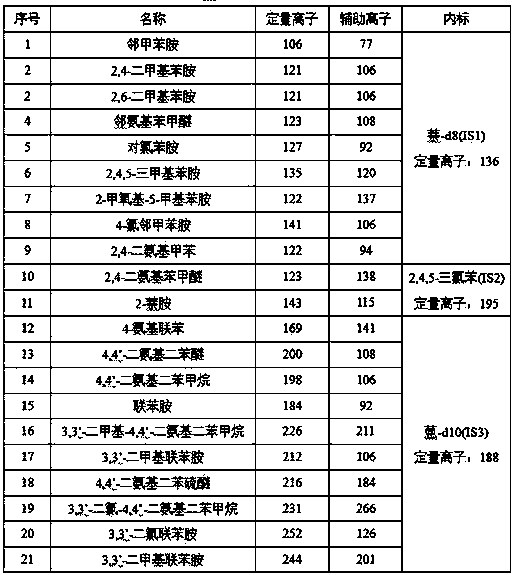

Method used

Image

Examples

Embodiment 1

[0039] (1) Cut the white cardboard to be tested to 0.6 dm 2 Take the sample to be tested, spread the sample to be tested on the bottom of the container, with the food contact surface facing up, spread 3 g of Tenax on the surface of the sample to be tested, and then place it at 150°C for 24 hours at a constant temperature , then cooled to room temperature; adopt the time conditions and temperature conditions of Table 1 and Table 2 to control:

[0040] Table 1 Test time conditions

[0041] Exposure time under the most severe foreseeable use conditions Test time t ≤5min 5 minutes 5 min≤ t ≤ 0.5 hours 0.5 h 0.5h≤ t ≤ 1 h 1 h 1h≤ t ≤ 2 hours 2 h 2h≤ t ≤ 4 hours 4 h 4h≤ t ≤ 24 hours 24 h t >24 h 240 h

[0042] Table 2 Temperature conditions of the test

[0043] Exposure temperature under the most severe foreseeable use conditions Test temperature T ≤5 ℃ 5 ℃ 5 ℃< T ≤20 ℃ 20 ℃ 20 ℃< T ≤40 ℃ 4...

Embodiment 2

[0060] (1) Cut the sulfuric acid paper to be tested to 1.0 dm 2 Take the sample to be tested, spread the sample to be tested on the bottom of the container, with the food contact surface facing up, spread 5 g of Tenax on the surface of the sample to be tested, and then place it at 20°C for 240 h , then cooled to room temperature; adopt the time condition and temperature condition of table 1 and table 2 to control;

[0061] (2) Take out 5.0 g of Tenax of the sample to be tested in step (1), put it in a stoppered Erlenmeyer flask, add 1:1 (v / v) ethyl acetate at a solid-to-liquid ratio (g / mL) of 1:10 The ester-tert-butyl methyl ether solution was shaken and extracted at room temperature for 0.5 h to obtain an extract, then the extract was concentrated to dryness at 35°C under nitrogen blowing, and 2.0 mL of tert-butyl methyl ether was added to dissolve to obtain a solution;

[0062] (3) Same as embodiment 1;

[0063] (4) Same as embodiment 1;

[0064] (5) According to the stan...

Embodiment 3

[0073] (1) Cut the paper or cardboard to be tested to 0.2 dm 2 Take the sample to be tested, spread the sample to be tested on the bottom of the container, with the food contact surface facing up, spread 1 g of Tenax on the surface of the sample to be tested, and then place it at 100°C for 5 minutes , then cooled to room temperature; adopt the time condition and temperature condition of table 1 and table 2 to control;

[0074] (2) Take out 1.0 g of Tenax of the sample to be tested in step (1), put it in a stoppered Erlenmeyer flask, add 1:1 (v / v) ethyl acetate at a solid-to-liquid ratio (g / mL) of 1:10 The ester-tert-butyl methyl ether solution was shaken and extracted at room temperature for 0.5 h to obtain an extract, then the extract was concentrated to dryness at 35°C under nitrogen blowing, and 2.0 mL of tert-butyl methyl ether was added to dissolve to obtain a solution;

[0075] (3) Same as embodiment 1;

[0076] (4) Same as embodiment 1;

[0077] (5) According to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com