Method for preparing cadmium telluride thin-film solar cell

A technology of solar cells and cadmium telluride, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as waste of raw materials, poor repeatability and discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

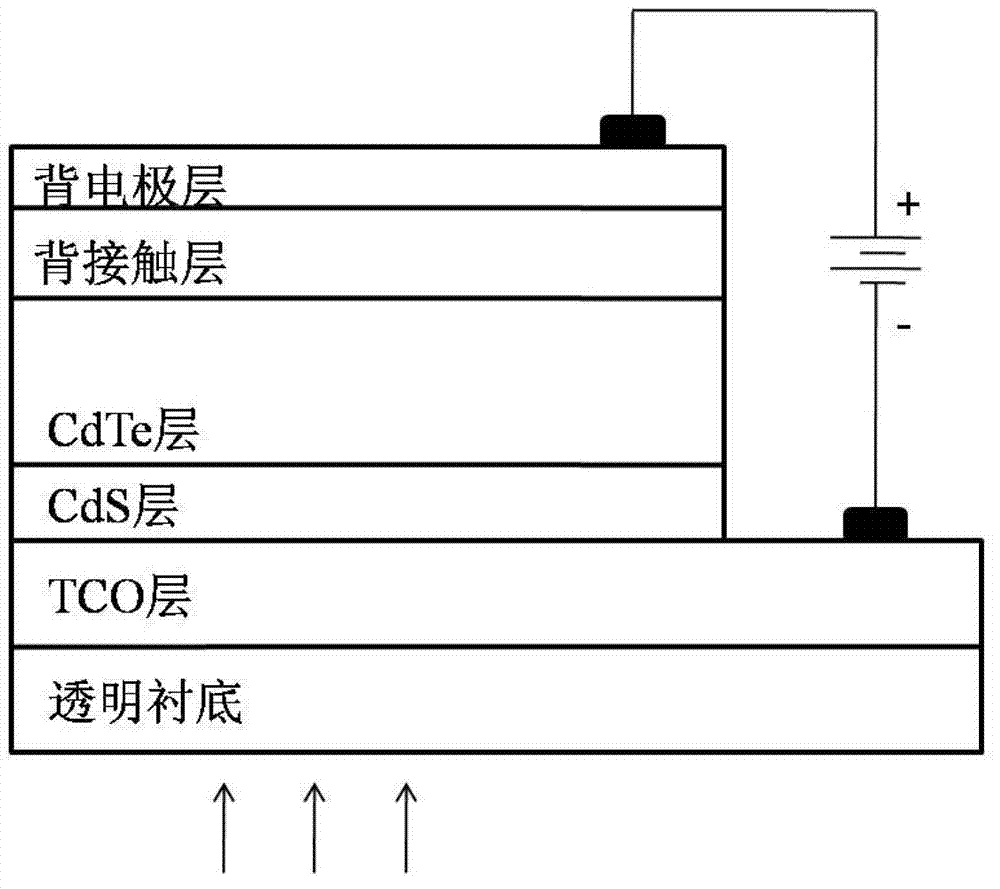

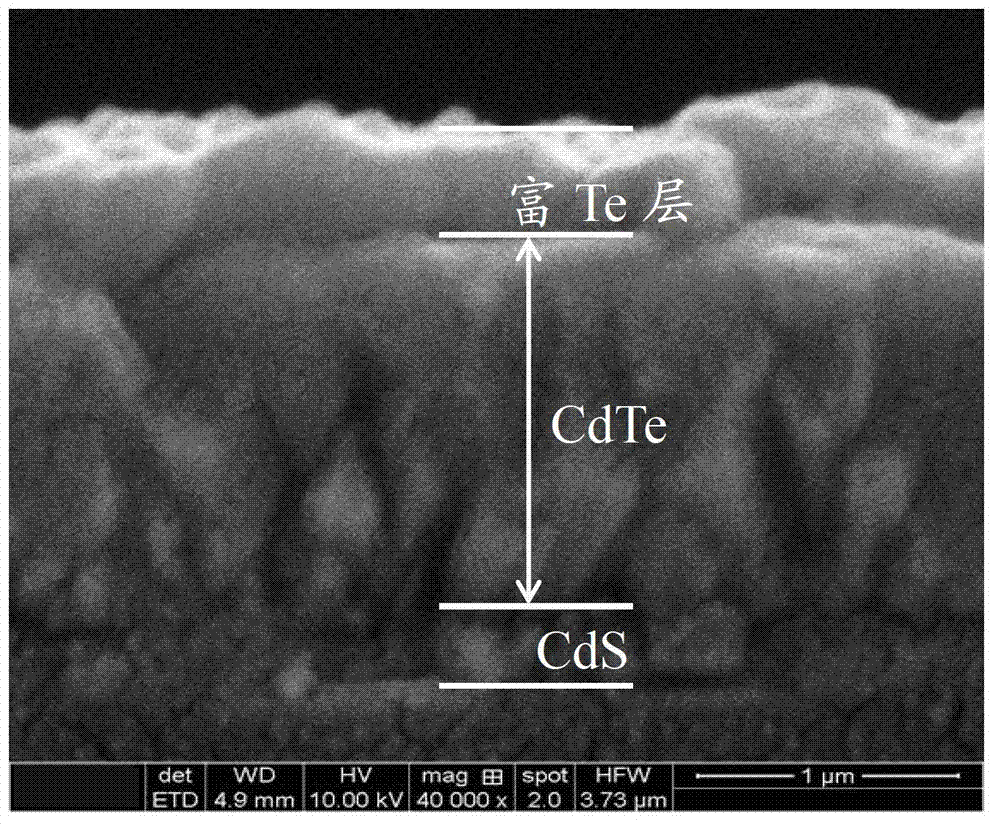

[0038] A method for preparing a cadmium telluride thin-film solar cell described in this embodiment comprises using glass as a transparent substrate, sequentially preparing a TCO layer, a CdS layer, a CdTe layer on the transparent substrate, and preparing a Te-rich layer on the CdTe layer. , preparing a back contact layer and a back electrode layer sequentially on the Te-rich layer.

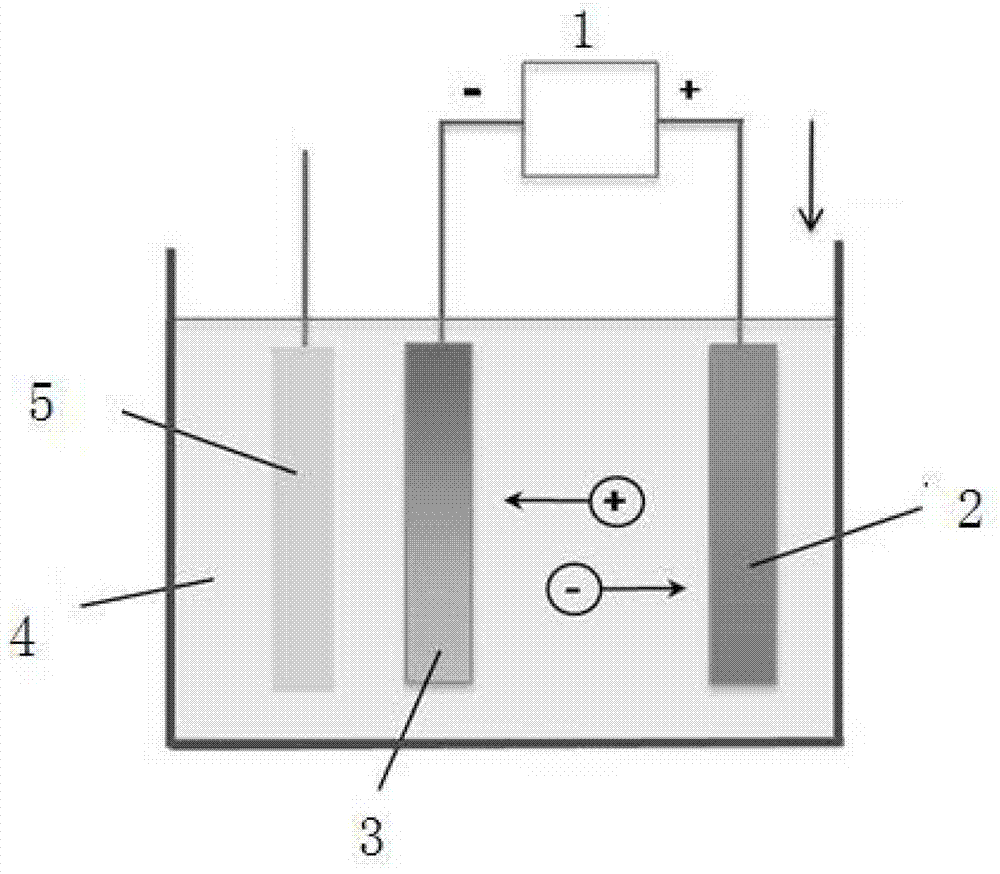

[0039] Wherein, the preparation method of the TCO layer, the CdS layer, the CdTe layer, the back contact layer and the back electrode layer refers to the prior art, which can be obtained by physical vapor deposition, closed space sublimation, and vapor transport deposition. , sputtering method, electrolytic deposition method, spray deposition method, organic metal chemical vapor deposition method, screen printing deposition method, chemical bath deposition method and other methods, the preferred embodiment of the present invention is specifically:

[0040] S1. Deposit the transparent conductive l...

Embodiment 2

[0045] A method for preparing a cadmium telluride thin-film solar cell described in this embodiment comprises using glass as a transparent substrate, sequentially preparing a TCO layer, a CdS layer, a CdTe layer on the transparent substrate, and preparing a Te-rich layer on the CdTe layer. , preparing a back contact layer and a back electrode layer sequentially on the Te-rich layer.

[0046] Wherein, the preparation method of the TCO layer, the CdS layer, the CdTe layer, the back contact layer and the back electrode layer refers to the prior art, which can be obtained by physical vapor deposition, closed space sublimation, and vapor transport deposition. , sputtering method, electrolytic deposition method, spray deposition method, organic metal chemical vapor deposition method, screen printing deposition method, chemical bath deposition method and other methods, the preferred embodiment of the present invention is specifically:

[0047] S1. Prepare a TCO layer and a CdTe layer...

Embodiment 3

[0052] A method for preparing a cadmium telluride thin-film solar cell described in this embodiment comprises using glass as a transparent substrate, sequentially preparing a TCO layer, a CdS layer, a CdTe layer on the transparent substrate, and preparing a Te-rich layer on the CdTe layer. , preparing a back contact layer and a back electrode layer sequentially on the Te-rich layer.

[0053] Wherein, the preparation method of the TCO layer, the CdS layer, the CdTe layer, the back contact layer and the back electrode layer refers to the prior art, which can be obtained by physical vapor deposition, closed space sublimation, and vapor transport deposition. , sputtering method, electrolytic deposition method, spray deposition method, organic metal chemical vapor deposition method, screen printing deposition method, chemical bath deposition method and other methods, the preferred embodiment of the present invention is specifically:

[0054] S1. Prepare a TCO layer and a CdTe layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com