Mask unit and substrate processing device

A substrate processing device and substrate technology, which is applied in the direction of exposure devices, electrical components, optics, etc. of photolithography, and can solve the problems such as the inability to obtain projection image adjustment functions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, refer to Figure 1 to Figure 7 Embodiments of the mask unit and the substrate processing apparatus of the present invention will be described.

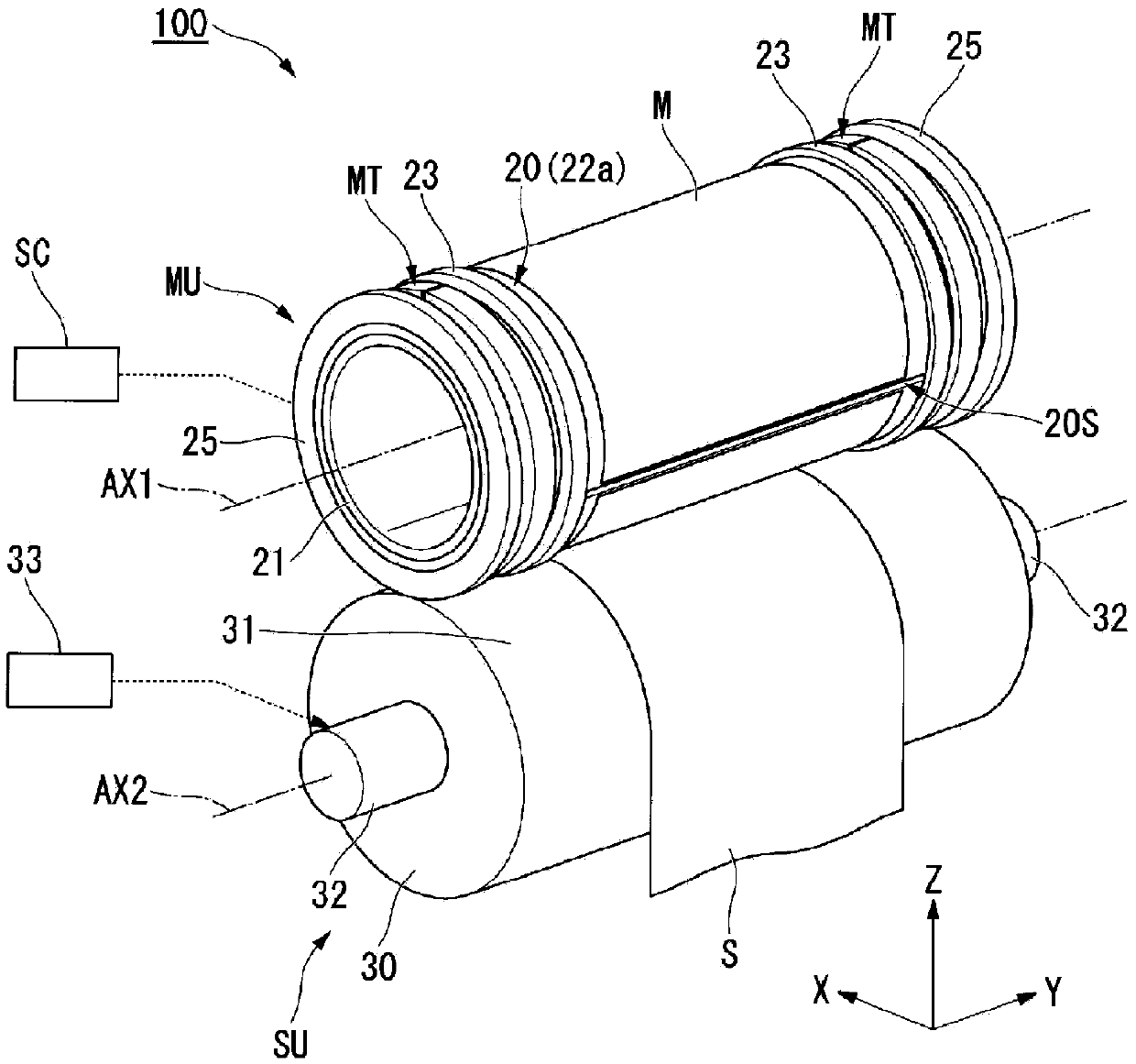

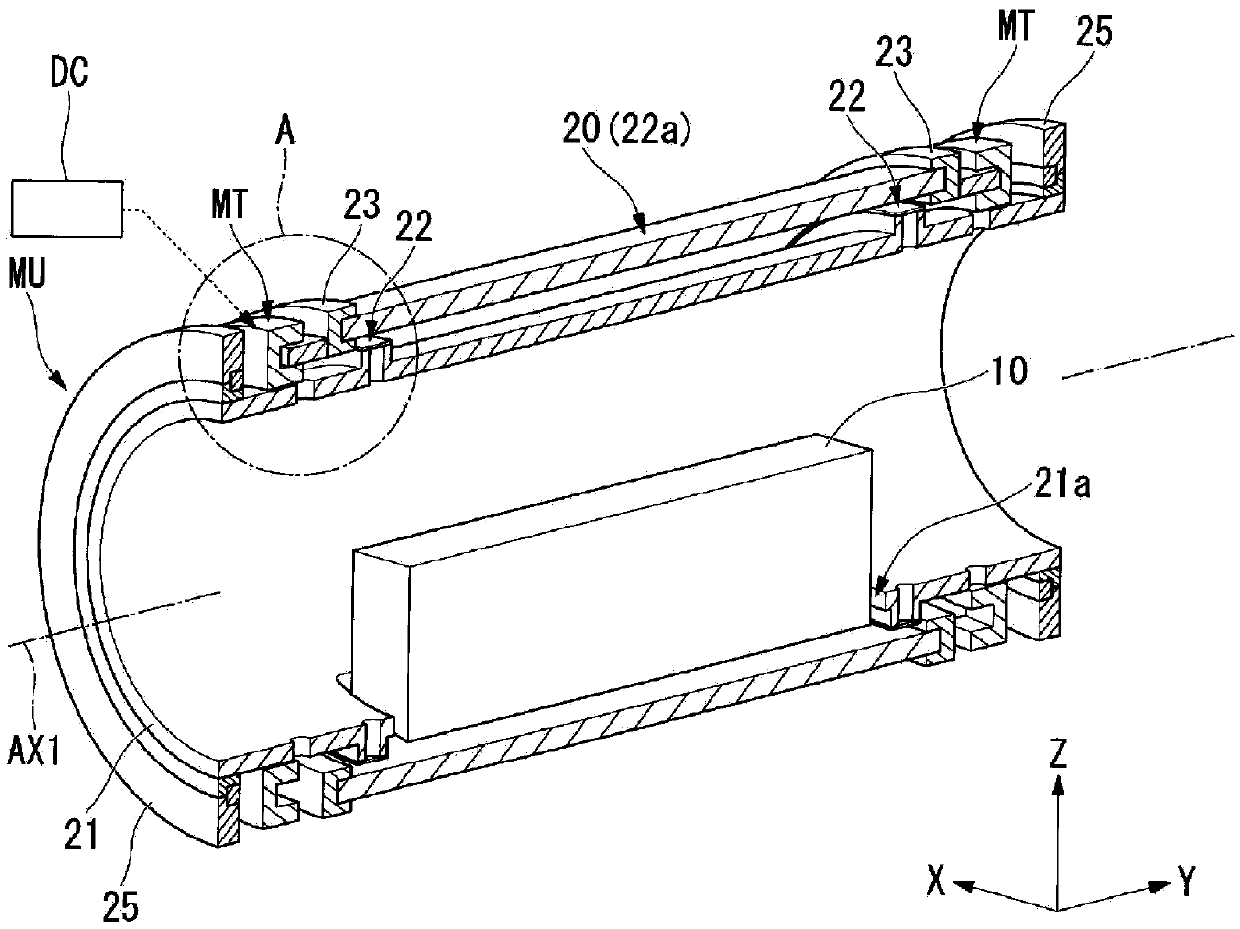

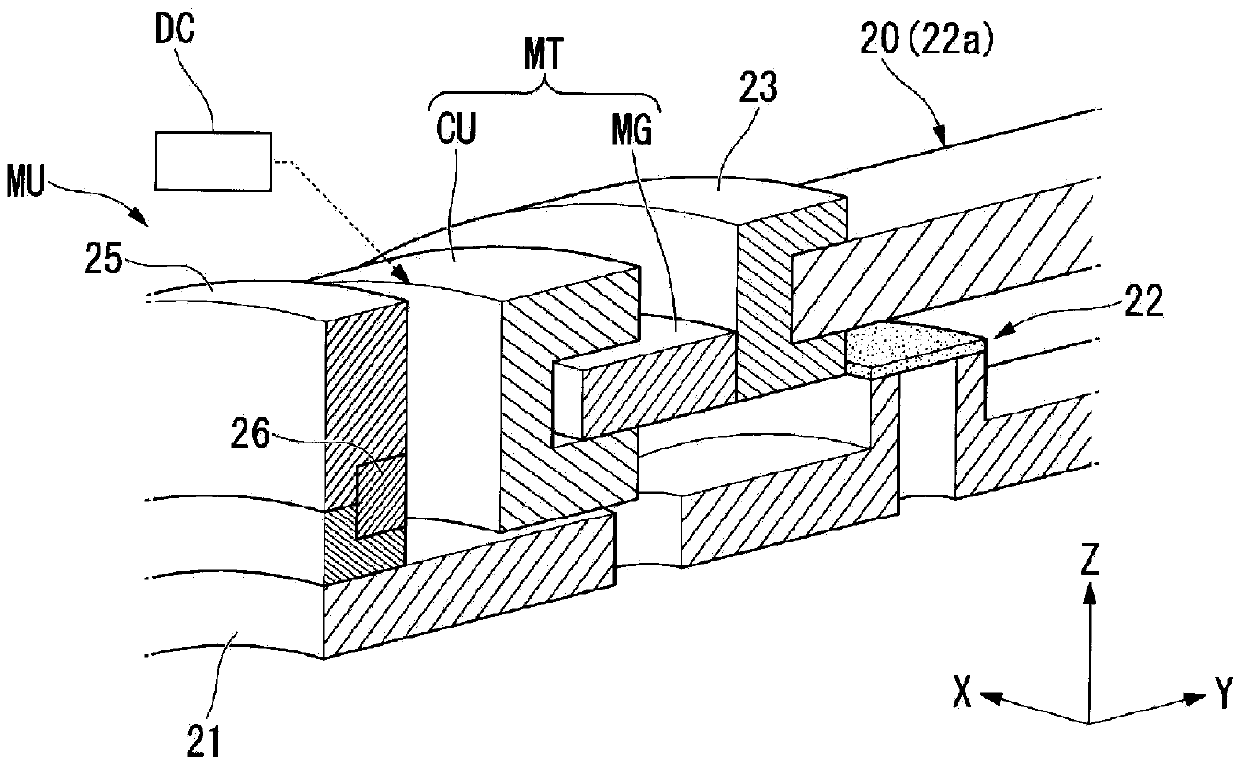

[0030] figure 1 It is a schematic external perspective view of a substrate processing apparatus 100 including a rotatable cylindrical mask unit MU and a sheet (substrate) S holding unit SU. figure 2 It is cut with the plane containing its axis of rotation AX1 figure 1 Cross-sectional view of the cylindrical mask unit MU in . image 3 is true figure 2 A magnified view of part A.

[0031] The substrate processing apparatus 100 is an apparatus for exposing a strip-shaped substrate (for example, a strip-shaped film member) S to a pattern of a flexible sheet-shaped mask M. The substrate processing apparatus 100 is mainly composed of an illumination unit 10 ( figure 1 not shown in the figure, refer to figure 2 ), a mask unit MU, a substrate holding unit SU, and a control unit (not shown).

[0032] In this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com