Device and Control Method for Slow Cooling Section of Radiation Cooling System of Horizontal Annealing Furnace

A technology of radiation cooling and control method, which is applied in the field of metallurgical heat treatment and annealing, can solve the problems of easily moving atmosphere, increased investment in equipment structure, unfavorable maintenance and overhaul, etc., and achieves the effect of stable cooling rate, simple control method, uniform and slow cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Implementation control method of the present invention is:

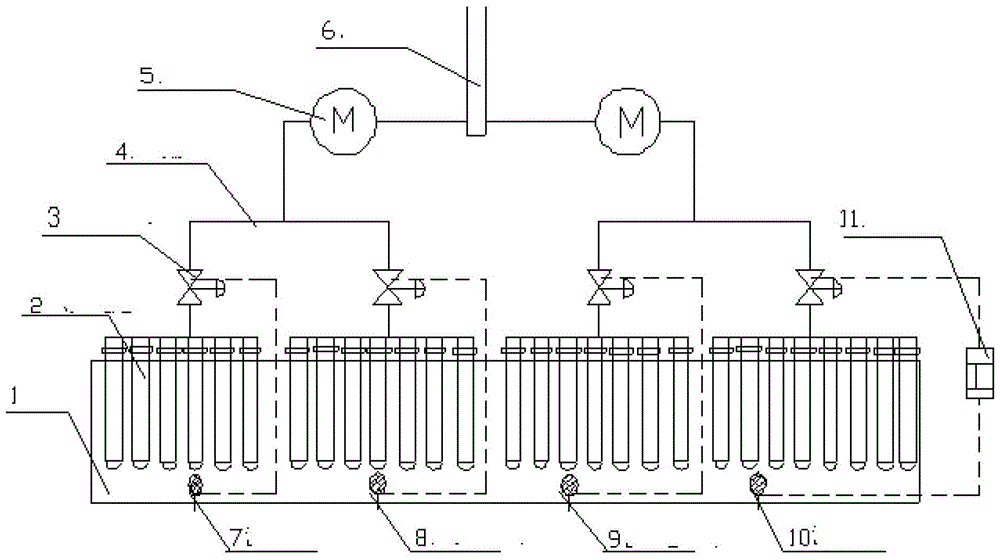

[0070] The entire slow cooling section can be divided into 4-8 sections, each section (or two sections) can be equipped with an exhaust fan, and fans with different power can be configured according to actual needs.

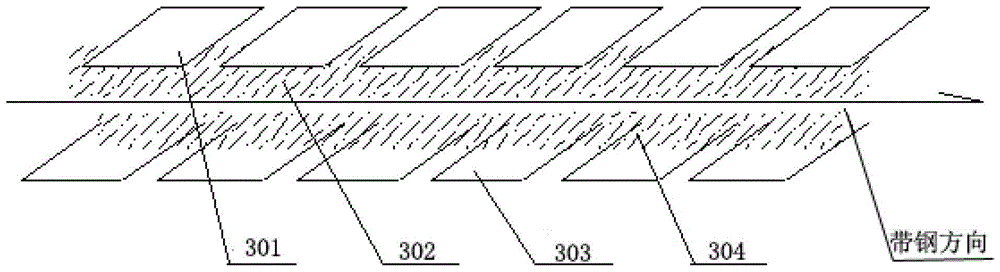

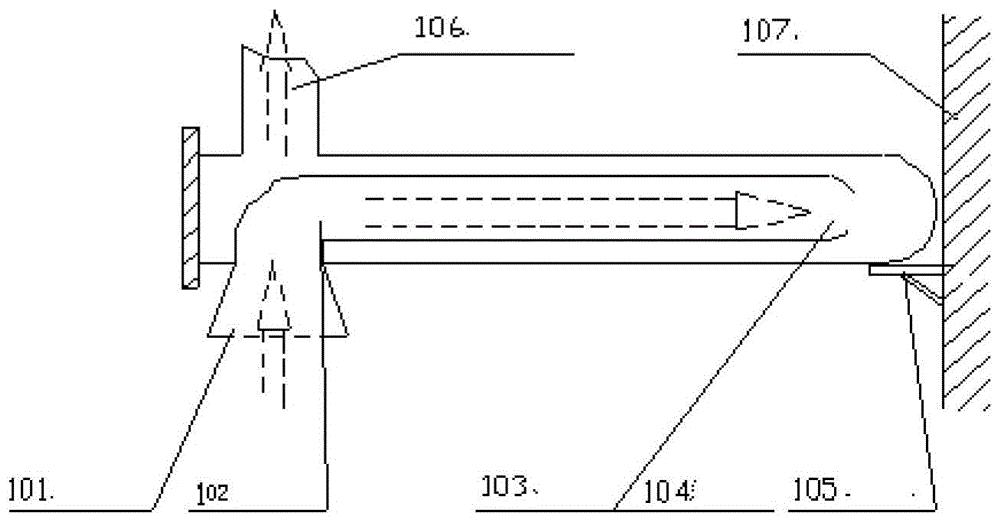

[0071] According to the cooling requirements, a certain number of radiation cooling jackets are arranged in each section, and the radiation cooling pipes are arranged crosswise on the upper and lower surfaces of the strip.

[0072] The distance between the upper and lower cooling radiant sleeves and the steel strip is controlled at 50mm--150mm.

[0073] A temperature detector is installed in each section, a flow regulating valve is installed on the air discharge pipe, and the air flow of the radiant tube is adjusted through the information feedback controller, so as to achieve the purpose of adjusting the temperature in the furnace.

[0074] The layout of the radiant tubes in the furnace is as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com