A kind of high-strength quality steel plate q550ez35 with a thickness of 300mm and its production method

A technology of Q550EZ35 and production method, applied in the direction of improving process efficiency, etc., can solve the problem of high production cost, achieve the effect of low manufacturing cost, high internal flaw detection quality, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the implementation examples.

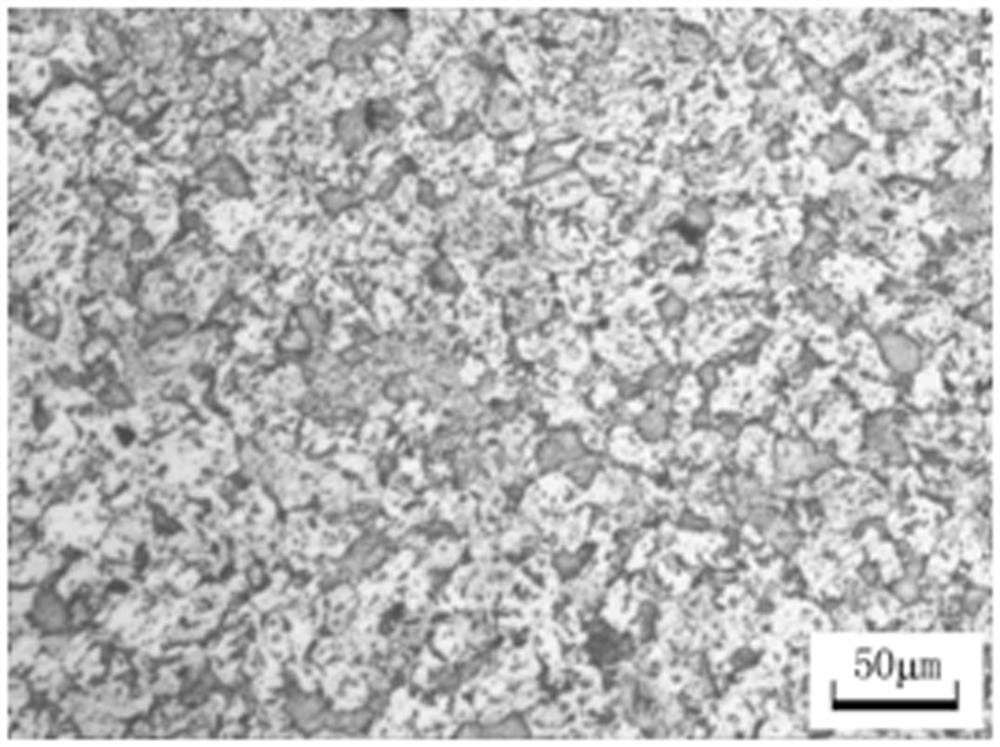

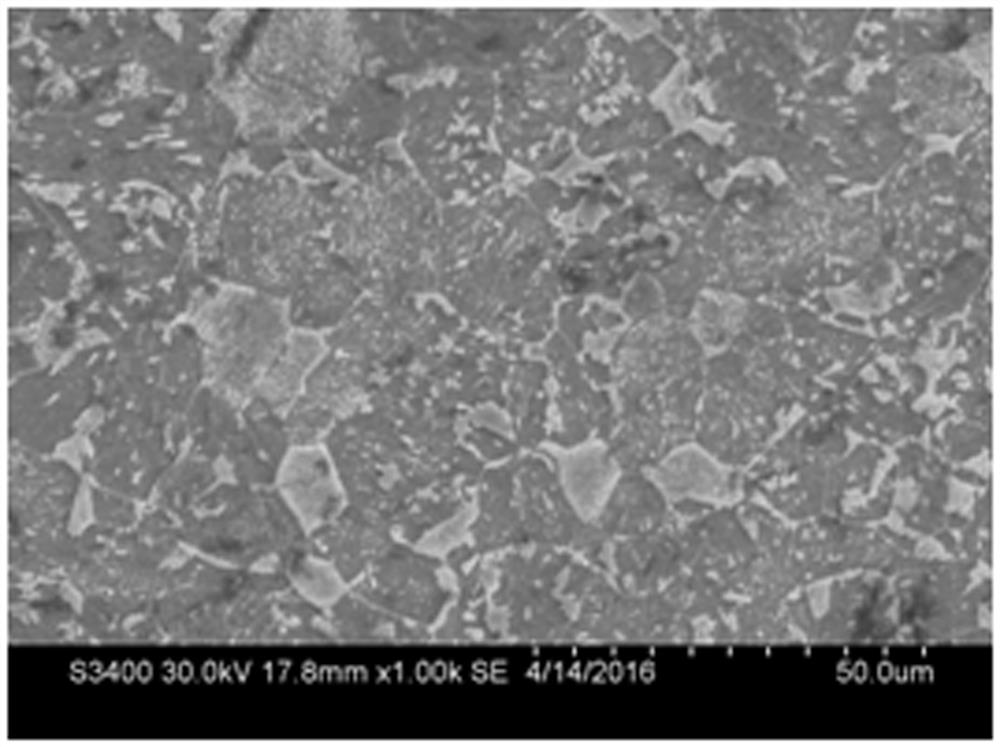

[0020] The grade of steel in this embodiment is Q550EZ35, the production thickness is 300mm, and the unit weight of the steel plate is 23.4t. It contains the following chemical composition: C: 0.12%, Si: 0.16%, Mn: 1.14%, P: 0.009%, S: 0.003%, Als: 0.053%, V: 0.056%, Ti: 0.007%, Cr: 0.62% , Ni: 1.34%, Mo: 0.44%, Nb: 0.037%, Cu: 0.014%, B: 0.00017%, of which Cr+Mo+V=1.116%, Ni+Nb=1.377%, CEV=0.62, others are Fe and residual elements.

[0021] The production steps of Q550EZ35 high-strength steel plate Q550EZ35 with a thickness of 300 mm in this implementation example are as follows:

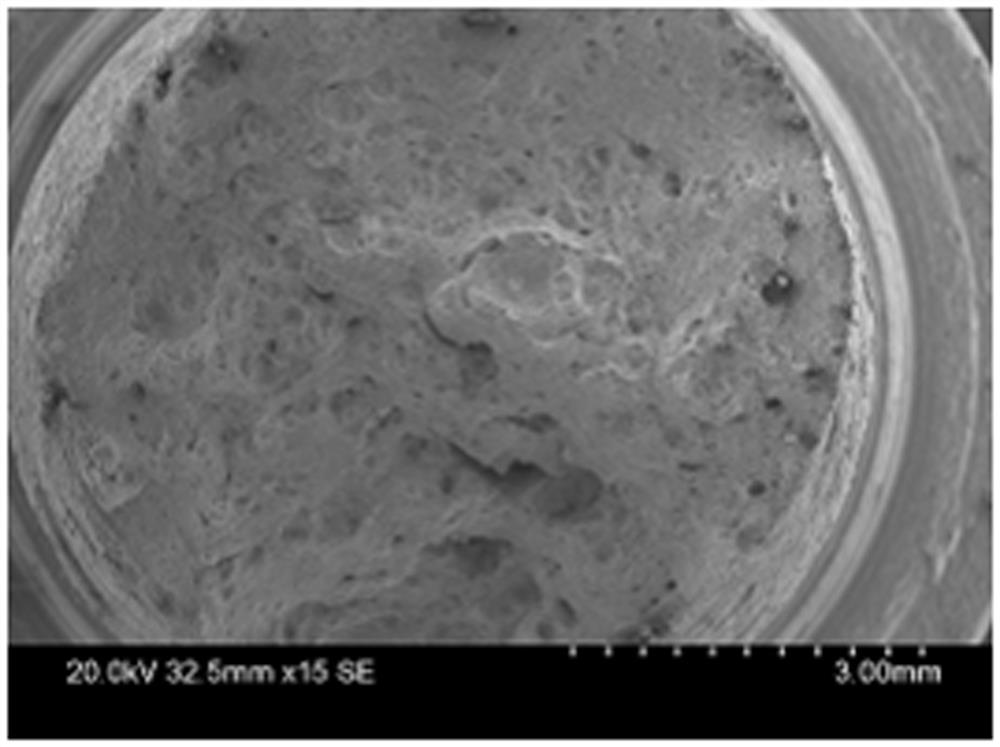

[0022] (1) Large steel ingot casting: water-cooled steel ingot thickness 700mm, compression ratio 2.7; after VD vacuum degassing treatment, hydrogen content 1.2PPm; casting temperature 1554 ℃, total casting time 23 minutes, of which the body casting time is 18 minutes, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com