Automobile anti-freezing cooling liquid and preparation method thereof

An antifreeze coolant and automobile technology, applied in the field of coolant, can solve the problems of affecting the cooling and anticorrosion effect of the coolant, affecting the service life of the cooling system, and unsatisfactory anticorrosion effect, so as to improve the anticorrosion effect, low cost, and good anticorrosion The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

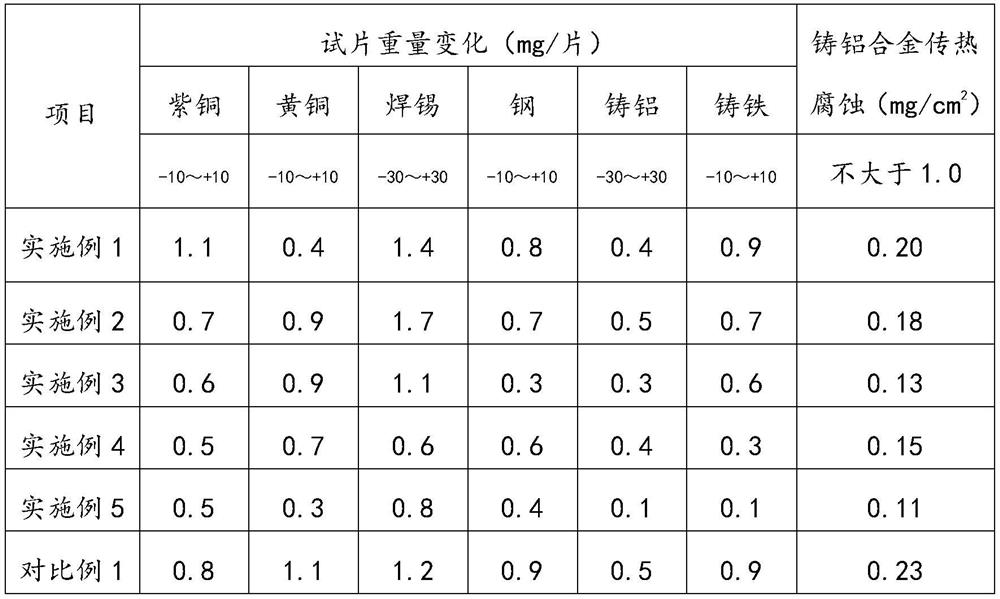

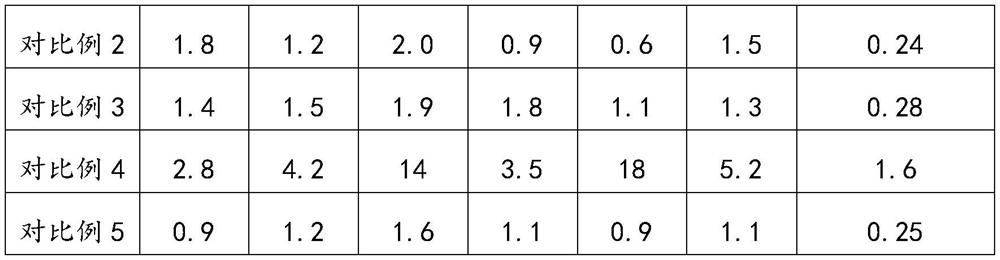

Examples

Embodiment 1

[0035] The preparation method of the automobile antifreeze coolant of the present embodiment includes the following steps:

[0036] S1. Mix 3.5kg of propylene glycol and 0.35kg of composite corrosion inhibitor, raise the temperature to 95°C, stir into a mixed liquid, and naturally cool to room temperature;

[0037] S2, heat 3.5kg of propylene glycol to 70°C, then add 1.5kg of PEG-200, stir and mix evenly, then add 80g of sodium polyaspartate and 2g of methyl blue in turn, stir for 10min, cool to room temperature, and then mix with step S1 The mixed liquids were mixed, and stirred for 5min to obtain a mixture;

[0038] S3. Add 1.048 kg of ionized water to the mixture in step S3, and after mixing evenly, add sodium hydroxide and stir to adjust the pH to 8.0, then add 200 g of glycerol polyoxypropylene ether, and stir evenly.

[0039] The above composite corrosion inhibitor is composed of 0.5kg of water-soluble polyaniline, 1.5kg of triazole silane compound, 0.5kg of capric acid...

Embodiment 2

[0046] The preparation method of the automobile antifreeze coolant of the present embodiment includes the following steps:

[0047] S1. Mix 4.0kg of propylene glycol and 0.43kg of composite corrosion inhibitor, raise the temperature to 100°C, stir into a mixed liquid, and naturally cool to room temperature;

[0048] S2, heat 4.0kg of propylene glycol to 75°C, then add 1.0kg of PEG-200, stir and mix evenly, then add 50g of sodium polyaspartate and 5g of methyl blue in turn, stir for 10min, cool to room temperature, and then mix with step S1 The mixed liquids were mixed, and stirred for 5min to obtain a mixture;

[0049] S3, add 0.505kg of ionized water to the mixture in step S3, after mixing evenly, add sodium hydroxide and stir to adjust the pH value to 8.0, then add 100g of polyoxyethylene polyoxypropylene pentaerythritol ether, and stir evenly.

[0050] The above-mentioned composite corrosion inhibitor is composed of 1kg of water-soluble polyaniline, 1kg of triazole silane ...

Embodiment 3

[0057] The preparation method of the automobile antifreeze coolant of the present embodiment includes the following steps:

[0058] S1. Mix 3.6kg of propylene glycol and 0.41kg of composite corrosion inhibitor, raise the temperature to 100°C, stir into a mixed liquid, and naturally cool to room temperature;

[0059] S2, heat 3.6kg of propylene glycol to 70°C, then add 1.45kg of PEG-200, stir and mix evenly, then add 65g of sodium polyaspartate and 5g of methyl blue in turn, stir for 10min, cool to room temperature, and then mix with step S1 The mixed liquid is mixed, and stirred for 10min to obtain a mixture;

[0060] S3. Add 0.852kg of ionized water to the mixture in step S3, and after mixing evenly, add sodium hydroxide and stir to adjust the pH to 8.0, then add 180g of glycerol polyoxypropylene ether, and stir evenly.

[0061] The above composite corrosion inhibitor is composed of 1kg of water-soluble polyaniline, 1.2kg of triazole silane compound, 0.7kg of capric acid, 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com