Air conditioner waste heat and waste energy power generation device

A technology for power generation and waste energy, applied in air conditioning systems, space heating and ventilation, generators/motors, etc., can solve problems such as power consumption, reduce power consumption, improve power generation efficiency, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

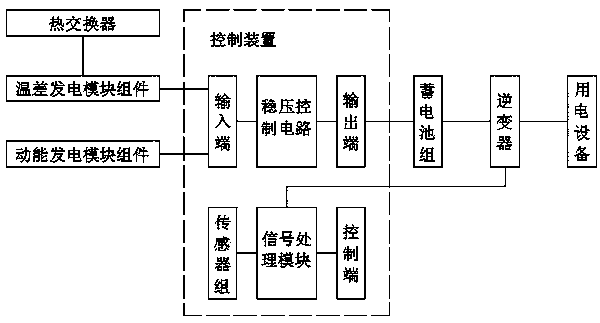

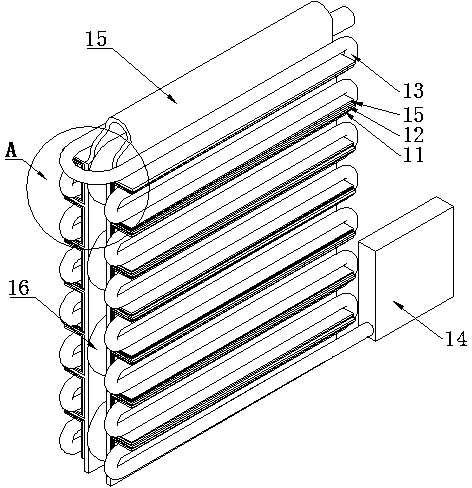

[0035] This embodiment is realized through the following technical solutions: including a heat exchanger, a thermoelectric power generation module assembly, a kinetic energy power generation module assembly and a control device; the heat exchanger includes a condensation pipe 16 and a finned cooling plate 15; The cross-section of the plate 15 is U-shaped, covering the outside of the condensation pipe 16 of the heat exchanger and clinging to the outer wall of the condensation pipe 16; And the cold medium storage 14; the cold medium storage 14 is internally connected to the cold medium circulation conduit 13, including a circulation pump and a coolant nozzle; the cold medium circulation conduit 13 is arranged in an S shape and embedded in the finned cooling plate 15 In the fin interval; the cold medium circulation conduit 13, the cold end conduction plate 12, the thermoelectric power generation module 11 and the fin cooling plate 15 are sequentially fastened and connected; the ki...

Embodiment 2

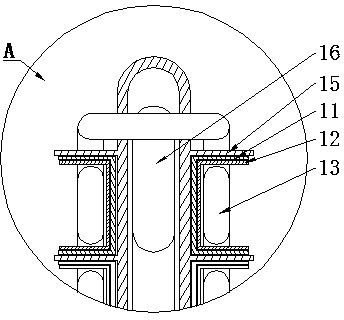

[0042] This embodiment is further optimized on the basis of the above embodiments. Further, the cross-section of the semiconductor thermoelectric power generation module 11 is U-shaped, and the cross-section of the cold end conduction plate 12 is U-shaped; the side wall of the cold medium circulation conduit 13 and the cold end The U-shaped inner surface of the conductive plate 12 is in close contact, the U-shaped outer surface of the cold-end conductive plate 12 is in close contact with the 11U-shaped inner surface of the semiconductor thermoelectric power generation module, and the 11U-shaped outer surface of the semiconductor thermoelectric power generation module is in close contact with the surface of the fin cooling plate 15 .

[0043] The U-shaped cold-end conduction plate 12 is tightly nested in the U-shaped thermoelectric power generation module 11, and the U-shaped inner surface of the U-shaped cold-end conduction plate 12 is in close contact with the conduit of the c...

Embodiment 3

[0045] This embodiment is further optimized on the basis of the above embodiments. Further, the sensor group includes a voltage sensor and a temperature sensor; the voltage sensor is connected to the battery pack; The temperature sensor A on the contact surface of the cooling plate 15 and the temperature sensor B provided on the contact surface of the thermoelectric power generation module 11 and the cold end conduction plate 12 .

[0046] The voltage sensor is used to collect voltage information at both ends of the battery pack. The temperature sensor is used to collect the temperature difference between the two ends of the thermoelectric power generation module 11; the temperature sensor A is used to collect the temperature of the contact surface between the thermoelectric power generation module 11 and the fin cooling plate 15; the temperature sensor B is used to collect the temperature difference The temperature of the contact surface between the power generation module 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com