Method for Cultivating Plants on Dolomite Slope Land

A technology for cultivating plants and cultivation methods, which is applied in the field of cultivating plants on dolomite slopes, can solve problems such as low fertility, poor water retention capacity, and difficulty in surviving, and achieve the effects of enhancing nutrient absorption capacity, solving technical problems, and ensuring growth and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 of the present invention: a kind of method of dolomite sloping cultivation plant, this cultivation method comprises the following steps:

[0023] A. First, use tools to dig a hole on the slope of the dolomite. After digging, the space of the hole is not less than 80cm*80cm*80cm;

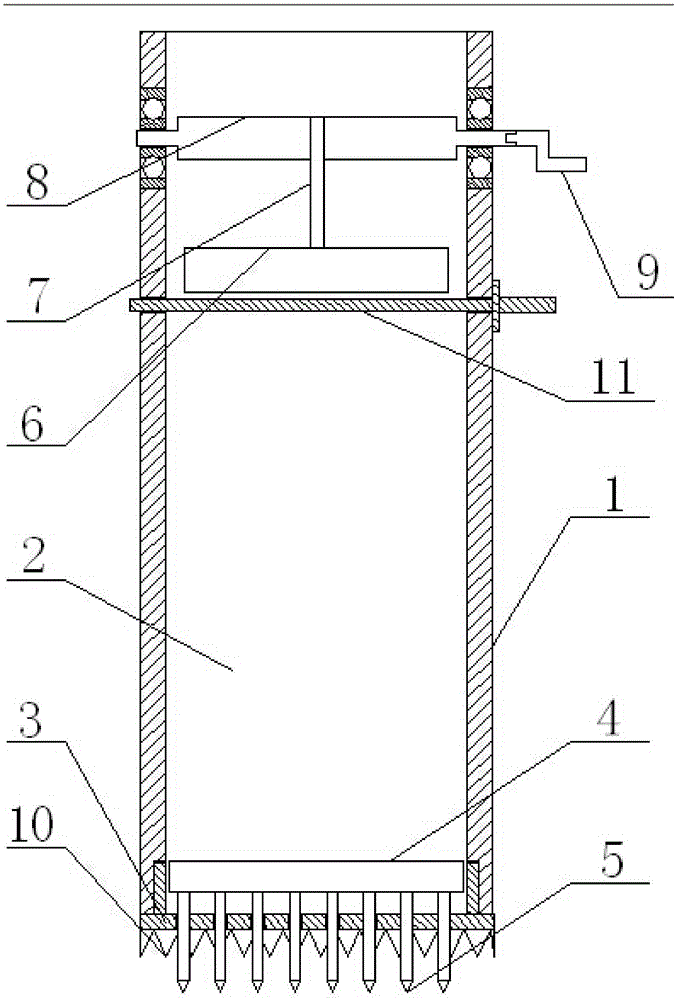

[0024] B. Put the rifter into the pit, and by operating the rifter, under the free-fall action of the heavy impact block 6 in the rifter, the chisel 5 below the rift head 4 hits the dolomite rock formation, causing the dolomite to be destroyed. create more and larger fissures;

[0025] C. Then put the water-retaining and fat-storing velvet cotton into the bottom of the dug pit;

[0026] D, plant is transplanted in the pit;

[0027] E. Finally, backfill the soil and pour enough water to set the root.

[0028] Using this method to cultivate plants has several advantages: First, more and larger cracks are dug in the dolomite rock formation through crackers, which expands the root ...

Embodiment 2

[0040] Embodiment 2 of the present invention: The difference between this embodiment 2 and embodiment 1 is that the production process of the water-retaining and fat-storage velvet cotton is slightly different. The manufacturing process of the water-retaining fat storage velvet cotton of present embodiment 2 comprises the following steps:

[0041] 1. Production of pure cotton knitted fabric velvet cotton: the shredded pure cotton knitted fabric is processed into velvet cotton through a popping machine, the finer the better. The pure cotton knitted fabric mainly uses discarded fabrics, which can save costs, and can turn waste into treasure, and when the plants survive, the lint cotton slowly rots, which not only provides nutrients for the plants, but also does not pollute the environment.

[0042] 2. Degreasing cotton knit fabric velvet: Tear off the finished cotton lint and pick out the impurities, such as small stones, undamaged fabrics, etc. Then wash the lint with water un...

Embodiment 3

[0046] Embodiment 3 of the present invention: The difference between this embodiment 3 and embodiment 1 is that the production process of the water-retaining and fat-storing velvet cotton is slightly different. The manufacturing process of the water-retaining fat storage velvet cotton of present embodiment 3 comprises the following steps:

[0047] 1. Production of pure cotton knitted fabric velvet cotton: the shredded pure cotton knitted fabric is processed into velvet cotton through a popping machine, the finer the better. The pure cotton knitted fabric mainly uses discarded fabrics, which can save costs, and can turn waste into treasure, and when the plants survive, the lint cotton slowly rots, which not only provides nutrients for the plants, but also does not pollute the environment.

[0048] 2. Degreasing cotton knit fabric velvet: Tear off the finished cotton lint and pick out the impurities, such as small stones, undamaged fabrics, etc. Then wash the lint with water un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com