System and method for treating gases containing VOC

A treatment system and treatment method technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as low treatment efficiency, increased burden on enterprises, and high treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

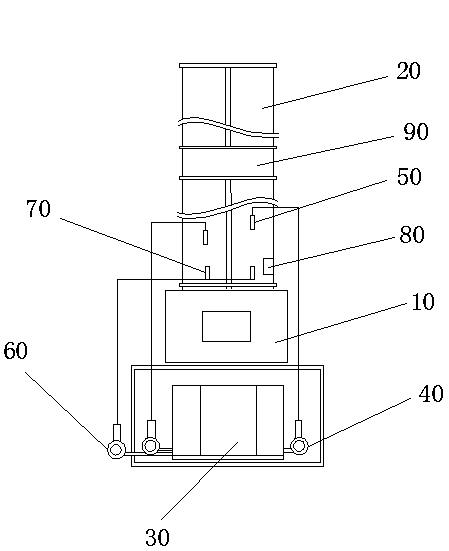

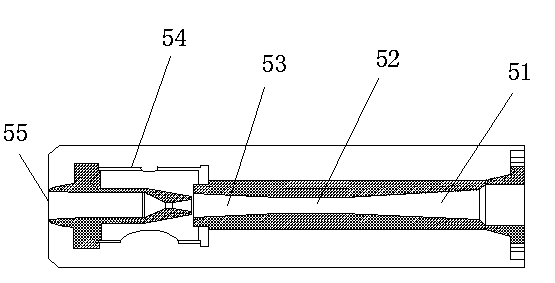

[0025] Such as figure 1 , figure 2 As shown, the treatment system containing VOC gas of the present embodiment includes the induced draft cabinet 10, the reaction tower 20, the circulating water device 30 and the nano-bubble device, and the nano-bubble device includes a nano-bubble booster pump 40 and a nano-bubble generator. device 50, the nano-bubble generator is connected to the circulating water device 30 through the nano-bubble booster pump 40, and the nano-bubble generator 50 is sequentially provided with a water flow tapered inlet 51, a booster pipe 52 for accelerating water flow, A tapered diffuser 53 for slow water flow, a turbulent flow tube 54 designed with holes on the tube wall, and a nano-bubble nozzle 55 for spraying nano-sized water bubbles. The nano-bubble nozzle ejects water bubbles with a diameter of 50-500 nanometers.

[0026] When carrying out the processing of the gas containing VOC, at first the gas containing VOC is introduced into the reaction tower...

Embodiment 2

[0034] Such as figure 1 , figure 2 As shown, this embodiment is a further improvement on Embodiment 1, requiring the nano-bubble nozzle 55 to spray nano-sized water bubbles to cover the entire cross-section of the reaction tower. This improvement enables the nano-scale water bubbles to fully mix with the gas containing VOC, reducing the VOC content in the gas to the greatest extent.

Embodiment 3

[0036] Such as figure 1 , figure 2 As shown, this embodiment is a further improvement on Embodiment 2, and the direction of the nanobubble nozzle 55 is opposite to the gas flow direction of the VOC-containing gas. This improvement makes the VOC-containing gas collide with nano-scale water bubbles, slows down the gas flow velocity containing VOC gas, prolongs the contact time between nano-scale water bubbles and VOC, makes the reaction time more sufficient, and improves the reaction efficiency. At the same time, the collision makes nano-scale water bubbles A vortex is formed between the gas containing VOC, which increases the success rate of combining nano-sized water bubbles with VOC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com