Injection molding insole, method for manufacturing injection molding insole and injection mold of injection molding insole

A technology of injection mold and surface layer, which is applied in the direction of shoe soles, household utensils, and other household utensils, etc., can solve the problems of great damage to human body, labor-intensive, easy to pollute the environment, etc., to save the procedure of brushing and bonding cardboard layers, The effect of avoiding physical damage and easy operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

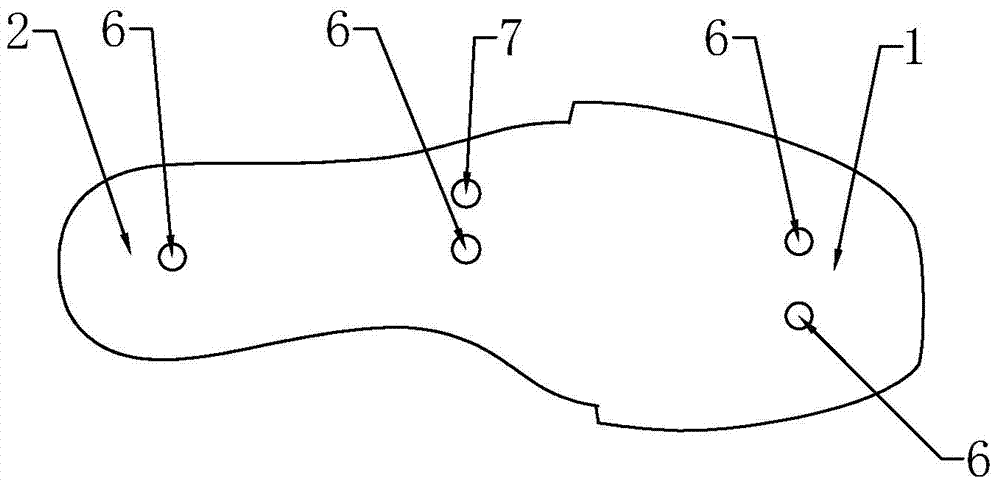

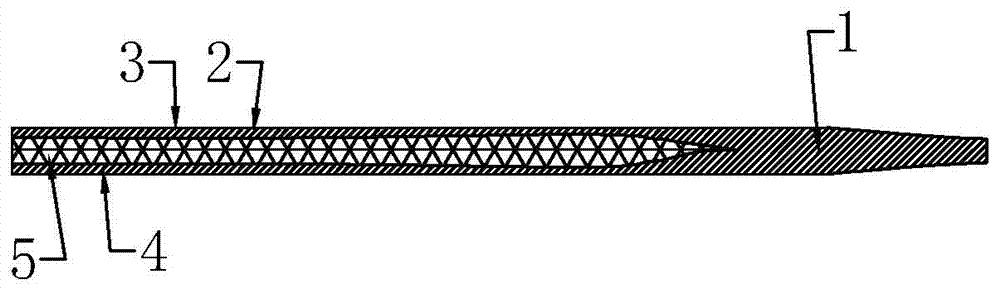

[0013] Such as figure 1 , figure 2 As shown, the injection molding midsole provided by the present invention includes a forefoot portion 1 and a heel portion 2, and the midsole also includes an upper surface layer 3 and a lower surface layer 4, and both the upper surface layer 3 and the lower surface layer 4 are cardboard layers or fiberboard layers or The needle-pricked cotton layer, because the injection molding material is not easy to bond, the upper surface layer 3 and the lower surface layer 4 mainly play the role of bonding with other parts of the sole, so materials with rough surfaces, easy bonding and easy splitting are selected. The upper surface layer 3 and the lower surface layer 4 of the part 2 are separated from each other, and at least part of the upper surface layer 3 and the lower surface layer 4 of the forefoot part 1 are bonded to each other, and a plastic layer 5 is injected between the upper surface layer 3 and the lower surface layer 4. Polypropylene is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com