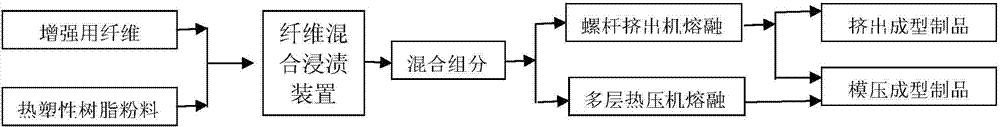

Preparation method of fiber-reinforced thermoplastic product

A fiber-reinforced and thermoplastic technology, which is applied in the field of fiber and recycled waste preparation, can solve the problems of less chance of contact with the rotary knife and the inability to disperse fiber bundles, etc., and achieve the effects of easy demoulding, easy dust cleaning and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

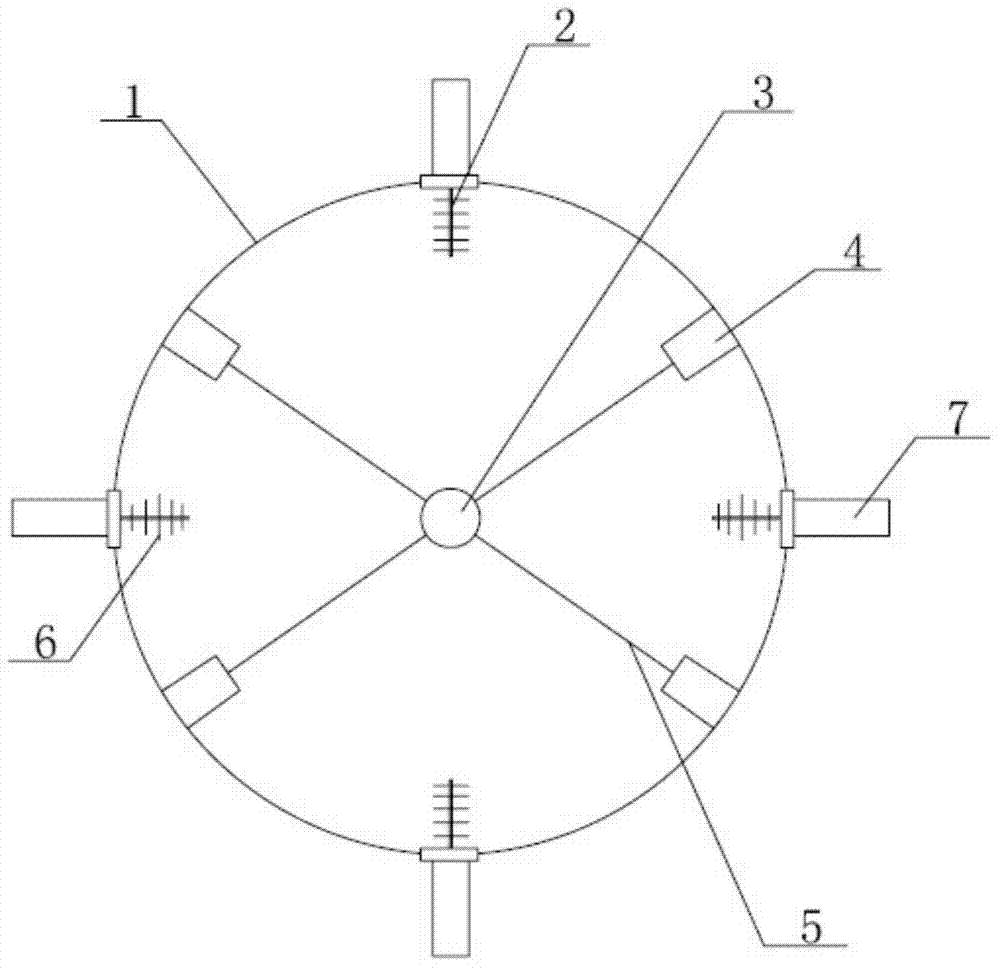

[0063] (1) Grind the thermoplastic resin into a 30-mesh powder with a pulverizer; then use a mixing and impregnating device (such as figure 2 As shown) the powder and 2cm of reinforcing fiber are mixed according to mass percentage 70%:30% to obtain a mixture; wherein the reinforcing fiber contains 30% glass fiber;

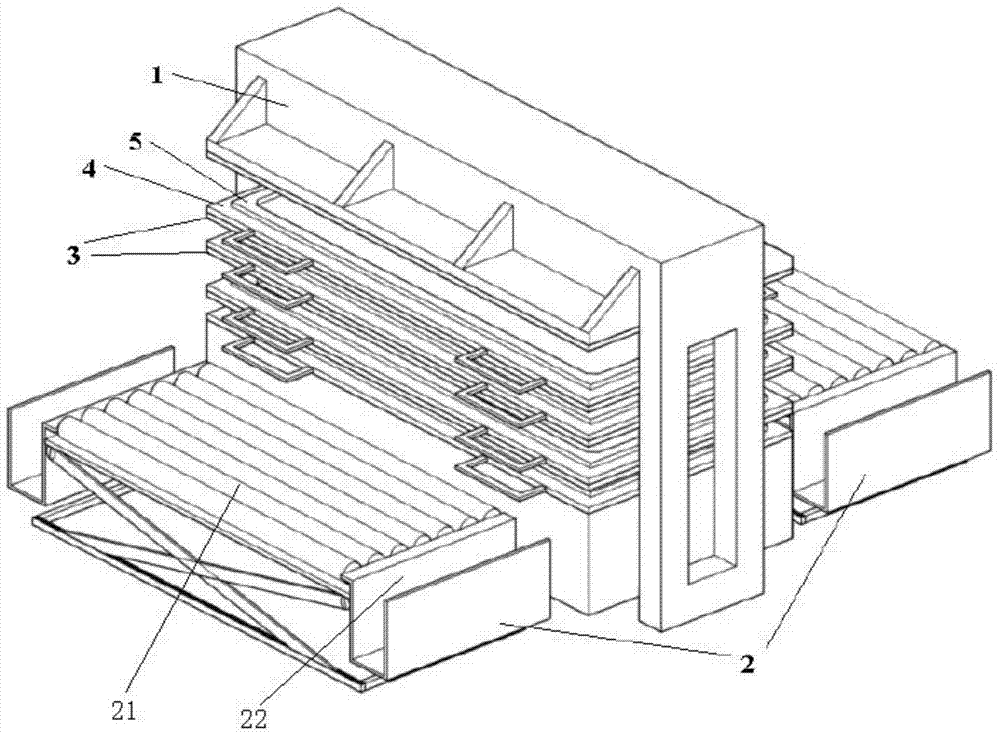

[0064] (2) Weigh 17.5 kg of the mixed material and spread it evenly on the molding die (lower plate: 3mm stainless steel plate; lower release cloth: 0.65mm thick Teflon cloth; iron frame: length 1900mm*width 800*height 8mm ; Upper release cloth: 0.65mm thick Teflon cloth), such as image 3 and 4 shown.

[0065] (3) Put the mold into the heating and melting multi-layer molding device (such as image 3 shown) for about 10 minutes to make the material temperature reach 220°C, turn on the heating press, uncover the upper and lower release cloths, remove the mold, fold the heated and melted material inwards until it is smaller than the size of the mold, and then put...

Embodiment 2

[0068] (1) Grinding the thermoplastic resin into a 20-mesh powder with a mill; then using a fiber mixing and impregnating device to mix the powder and 1.5 cm of reinforcing fibers at a mass percentage of 60%:40% to obtain a mixture; wherein, The reinforcing fiber contains 30% glass fiber;

[0069] (2) Get 100% of the above compound into the extrusion screw (such as Figure 8 Shown) to extrude the molten material;

[0070] (3) making molten material extrude width through die is 400mm, and height is 12.5 kilograms of molten material of 40mm;

[0071] (4) Put 12.5 kilograms of molten material into the mold of the molding machine, press and mold the closed molding machine, cool and set the shape, and obtain the brick machine pallet.

[0072]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com