High-pressure-resistant high-strength all-ceramic heat-resistant vessel and preparation method thereof

A high-strength, high-pressure-resistant technology, used in clay products, other household appliances, household appliances, etc., can solve the problems of high water absorption, high pressure resistance, and dull color of ordinary heat-resistant clay.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A high-pressure-resistant high-strength all-ceramic electric pressure cooker liner, the weight percentage composition of its blank and glaze formula is as follows:

[0029] Billet: 12% lithium china clay, 20% cooked quartz, 25% kaolin, 11% ball clay, 11% talc washing mud, 16% cooked alumina, 1.5% zinc oxide, 3.5% zirconia;

[0030] Among the above components, cooked quartz is a medium particle of 10-30um, cooked alumina is a particle powder of 1-3um, and zirconia is a fine material of 3-5um;

[0031] Glaze: Quartz 16%, cooked clay 21%, fine aluminum powder 6%, talc 4%, calcite 26%, kaolin 11%, boric acid 16%.

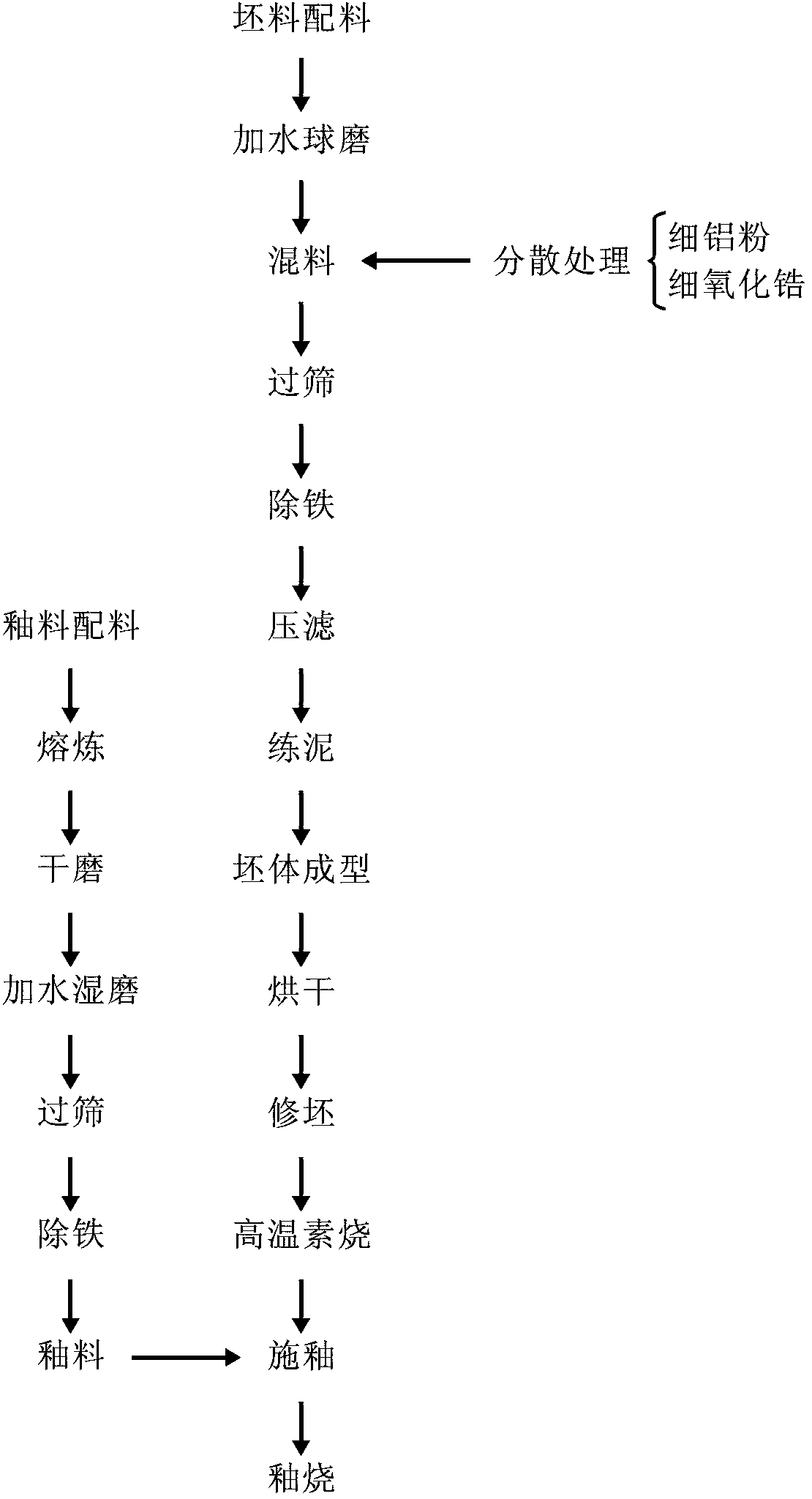

[0032] The preparation method of the above-mentioned high-pressure-resistant high-strength all-ceramic electric pressure cooker liner includes:

[0033] (1) Billet preparation: According to the above-mentioned billet formula and ingredients, carry out wet ball milling with lithium china clay, smelted quartz, kaolin, ball clay, talc washing mud, zinc oxide and wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com