Preparation method of porous composite isolating membrane

A technology of isolation film and base film, which is applied to household components, applications, electrical components, etc., can solve the problems of unfavorable cost control of electrochemical devices, increase the cost of isolation film, etc., so as to improve uneven tension, improve force, and improve quality products. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

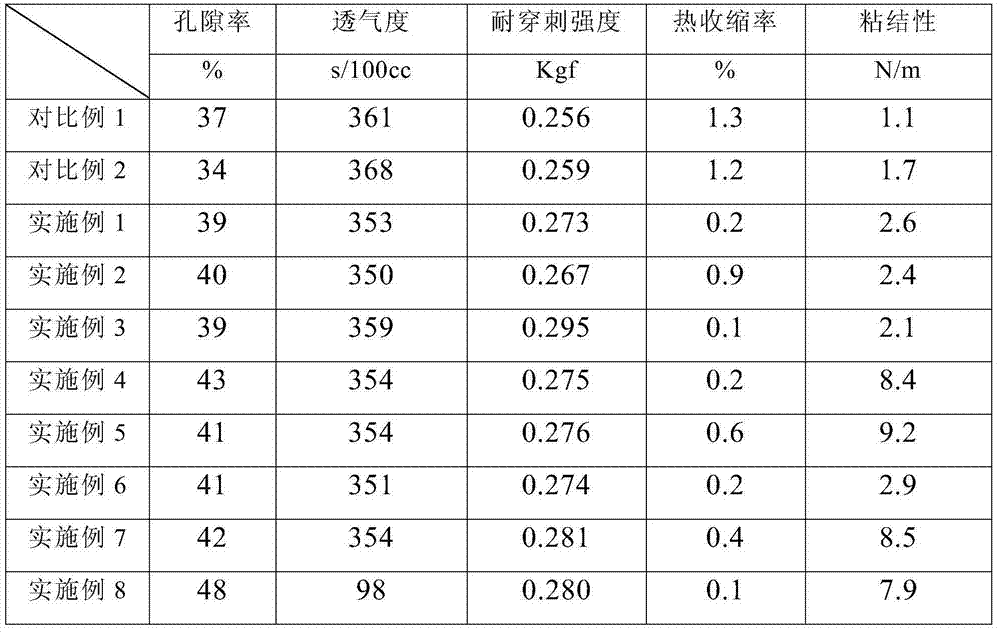

Examples

preparation example Construction

[0011] Firstly, the preparation method of the porous composite separator according to the present invention is described, including the steps: (1) forming process of the porous separator substrate: using organic particles as raw material to prepare the porous separator substrate; (2) functional material coating Coating process: coating the functional material coating on at least one surface of the obtained porous isolation membrane substrate to obtain a porous isolation membrane substrate with a functional material coating; (3) heat treatment process: coating the functional material The layer is dried, and the porous separator substrate and the functional material coating on the surface are heat-treated to obtain a porous composite separator.

[0012] In the preparation method of the porous composite isolation membrane according to the present invention, the coating process of the functional material coating is integrated into the traditional preparation process of the porous i...

Embodiment 1

[0039] (1) The molding process of the porous isolation film base material: the organic particle polyethylene, the plasticizer paraffin oil, and the solvent acetone are mixed in a weight ratio of 50:10:40, and then extruded through a twin-screw extruder, and the process is carried out horizontally and then vertically Stretching to form a base film, wherein the stretched base film has a transverse stretch rate of 900%, a longitudinal stretch rate of 700%, a thickness of 11 μm, and a width of 2.2 meters; then the stretched base film Immersed in the extractant dichloroethane to form a porous isolation membrane substrate.

[0040] (2) Coating process of functional material coating: Utilize the dipping coating method to apply aluminum oxide slurry (particle size is 0.6 μ m) on the two surfaces of the porous isolation membrane substrate after extraction to obtain wet membrane.

[0041] (3) Heat treatment process: The wet film is heat-set in a three-stage oven (the temperature of eac...

Embodiment 2

[0043] (1) The molding process of the porous isolation membrane base material: the organic particle polypropylene, the plasticizer dioctyl phthalate, the solvent N-methylpyrrolidone, and the filler calcium carbonate are mixed in a weight ratio of 45:8:30:17 After mixing, it is extruded by a single-screw extruder, and stretched longitudinally and then transversely to form a base film, wherein the transverse stretch rate of the stretched base film is 50%, the longitudinal stretch rate is 50%, and the thickness is 45 μm, and the width is 2.1 meters; after that, the stretched base film is immersed in the extractant n-hexane to form a porous isolation film substrate.

[0044] (2) Coating process of functional material coating: apply silica slurry (with a particle size of 0.01 μm) to one of the surfaces of the extracted porous isolation membrane substrate by spray coating method to obtain a wet film .

[0045] (3) Heat treatment process: The wet film is heat-set in a three-stage ov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com