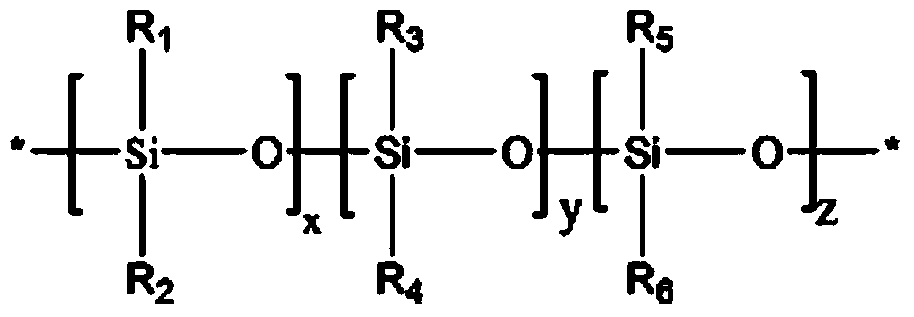

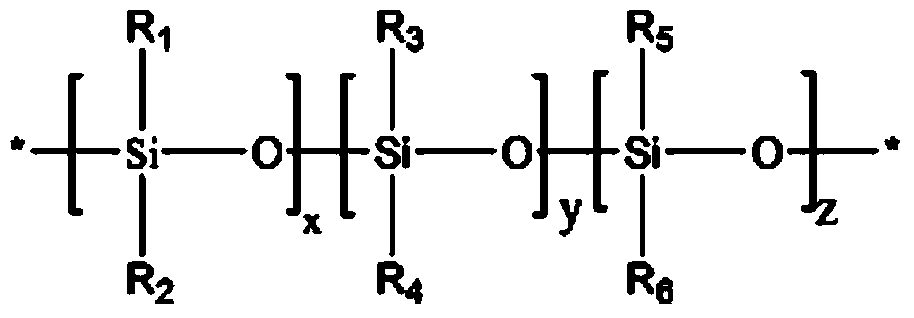

Polycarbonate composition of sulfur and nitrogen contained organic silicon flame retardant and preparation method

A polycarbonate and silicone technology, applied in the field of engineering plastics, can solve ecological problems and other problems, and achieve the effects of small optical performance, resource saving and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

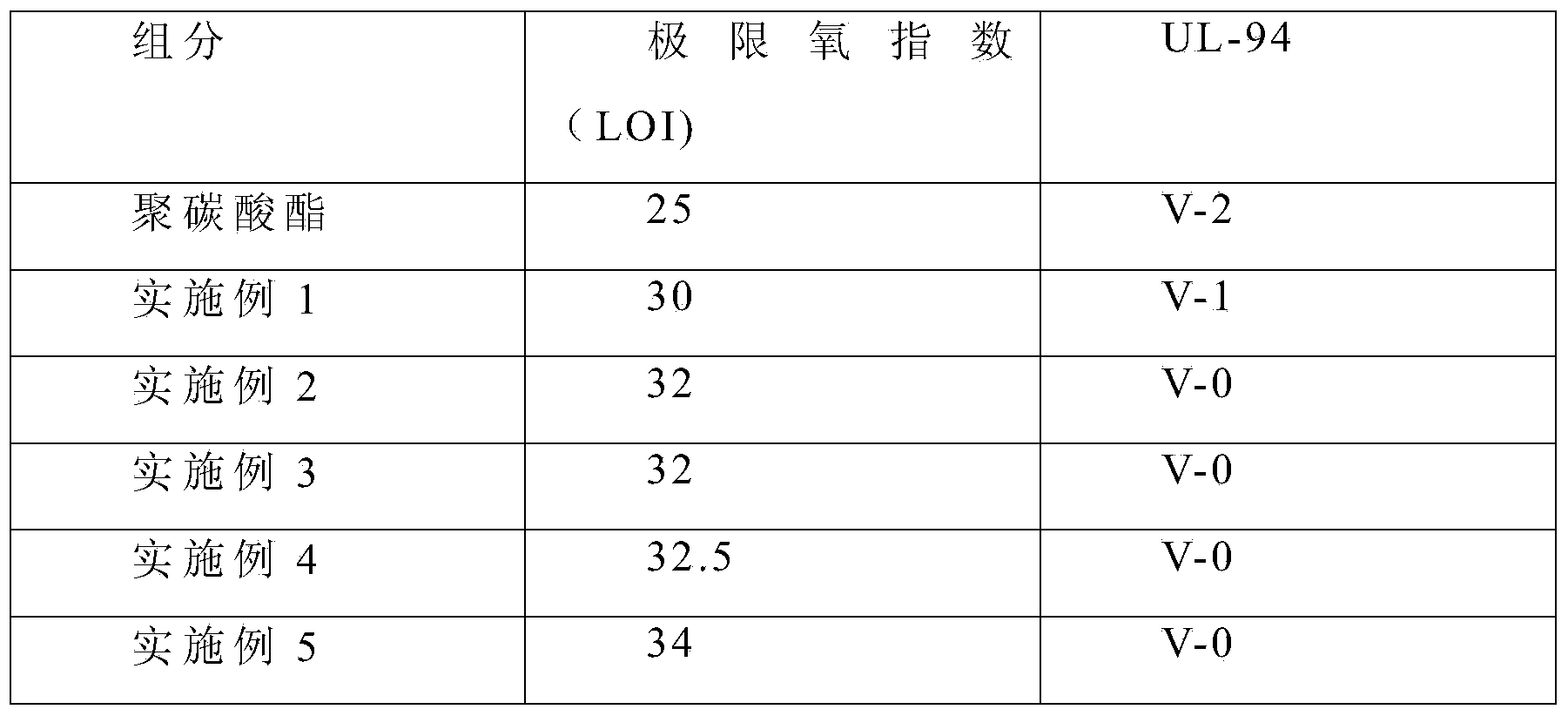

Embodiment 1

[0024] Get 0.5 part of the above-mentioned organosilicon flame retardant, 0.3 part of antioxidant 1010 and 99.2 parts of polycarbonate resin (LG Dow 201-22) in the extruder and mix and granulate for use (the temperature of each section is respectively set to: 200 °C, 240 °C, 245 °C, 220 °C, the rotation speed is 90rpm), molded at 230 °C to prepare samples to test the flame retardancy, measure the limiting oxygen index according to the national standard GB / T2406-93, and measure according to the national standard GB4609-84 Burn vertically.

Embodiment 2

[0026] Take 1 part of the above-mentioned silicone flame retardant, 0.3 part of antioxidant 1010 and 98.7 parts of polycarbonate (LG Dow 201-22) in the extruder and mix and granulate for use (the temperature of each section is set to 200 ° C , 240°C, 245°C, 220°C, the speed is 90rpm), molded at 230°C, the limiting oxygen index is measured according to the national standard GB / T2406-93, and the vertical combustion is measured according to the national standard GB4609-84.

Embodiment 3

[0028] Take 1.5 parts of the above-mentioned organosilicon flame retardant, 0.3 parts of antioxidant 1010 and 98.2 parts of polycarbonate in the extruder and mix and granulate them for later use (the temperature of each section is respectively set as: 200°C, 240°C, 245°C, 220°C, rotating speed 90rpm), molded at 230°C, the limiting oxygen index is measured according to the national standard GB / T2406-93, and the vertical combustion is measured according to the national standard GB4609-84.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com