Mixed refrigerant replacing HCFC-22 as well as preparation method and application thereof

A technology of mixing refrigerant and condensing temperature, applied to chemical instruments and methods, heat exchange materials, etc., to achieve great economic benefits, reduce energy consumption, and reduce charging volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

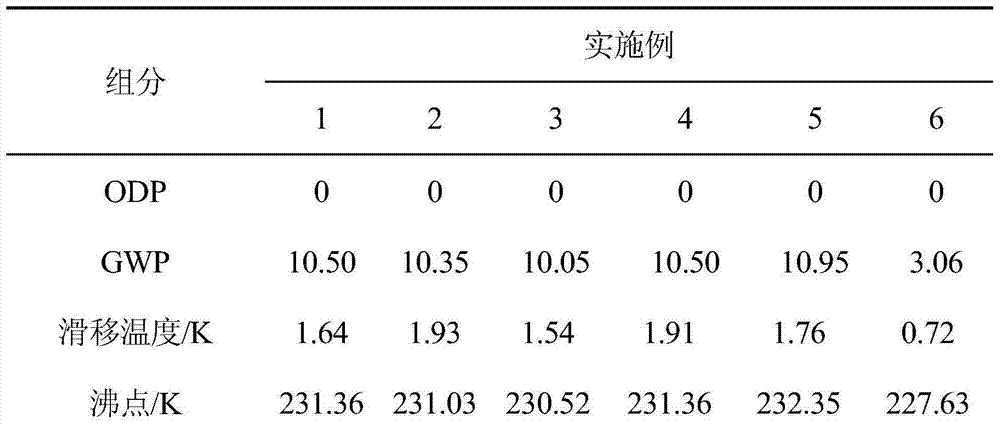

Embodiment 1

[0054] A mixed refrigerant that replaces HCFC-22 under high-temperature conditions, composed of the following three components by mass percentage: fluoroethane, 85%; propylene, 5%; propane, 10%.

[0055] When replacing HCFC-22 under high-temperature conditions, physically mix HFC-161, HC-1270, and HC-290 in a liquid phase at a mass percentage of 85:5:10 to obtain the above-mentioned mixed refrigerant.

Embodiment 2

[0057] A mixed refrigerant that replaces HCFC-22 under high-temperature conditions, composed of the following three components by mass percentage: fluoroethane, 85%; propylene, 10%; propane, 5%.

[0058] When replacing HCFC-22 under high-temperature conditions, physically mix HFC-161, HC-1270, and HC-290 in the liquid phase at a mass percentage of 85:10:5 to obtain the above-mentioned mixed refrigerant.

Embodiment 3

[0060] A mixed refrigerant that replaces HCFC-22 under high-temperature conditions, composed of the following three components by mass percentage: fluoroethane, 80%; propylene, 5%; propane, 15%.

[0061] When replacing HCFC-22 under high-temperature conditions, physically mix HFC-161, HC-1270, and HC-290 in a liquid phase at a mass percentage of 80:5:15 to obtain the above-mentioned mixed refrigerant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com