Method and system for improving thermal efficiency of setting machine

A setting machine, thermal efficiency technology, applied in heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc. Effectiveness of utilization efficiency and thermal efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

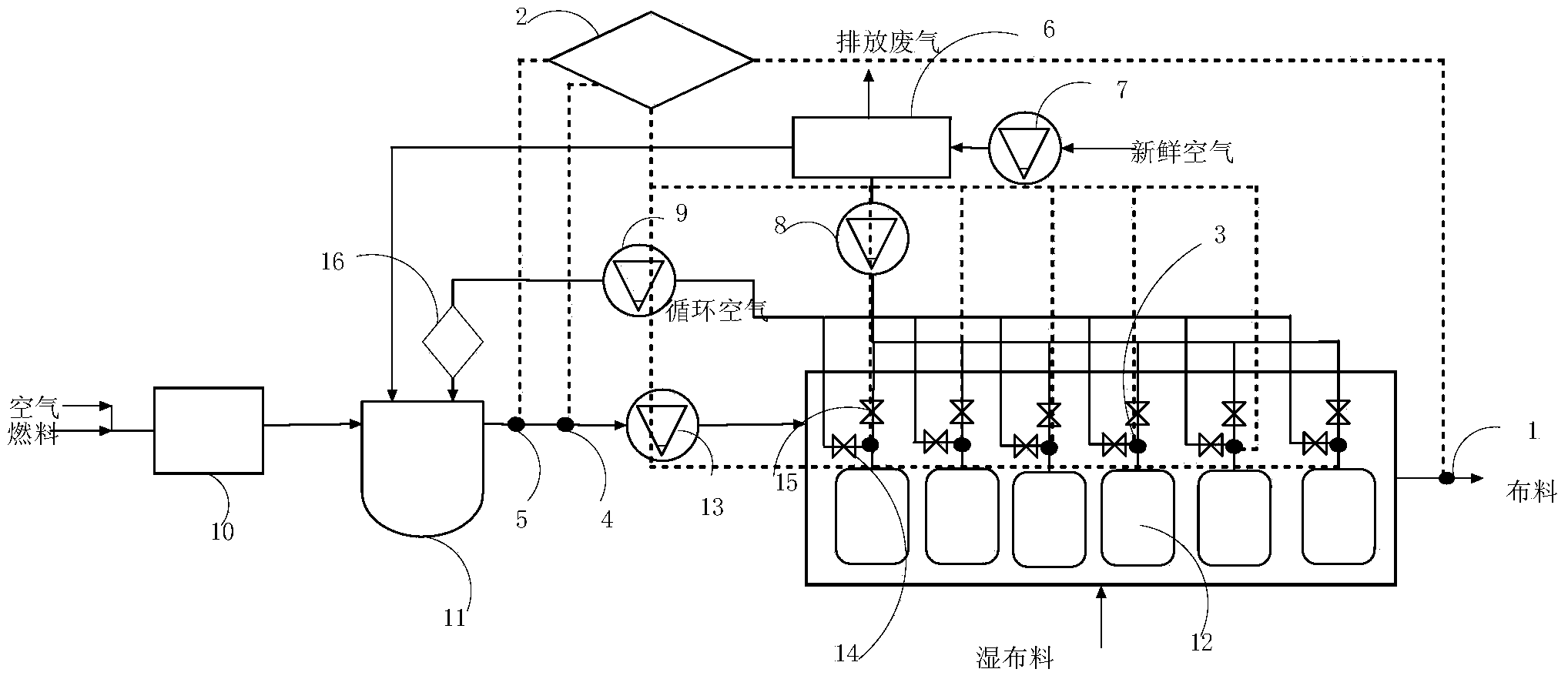

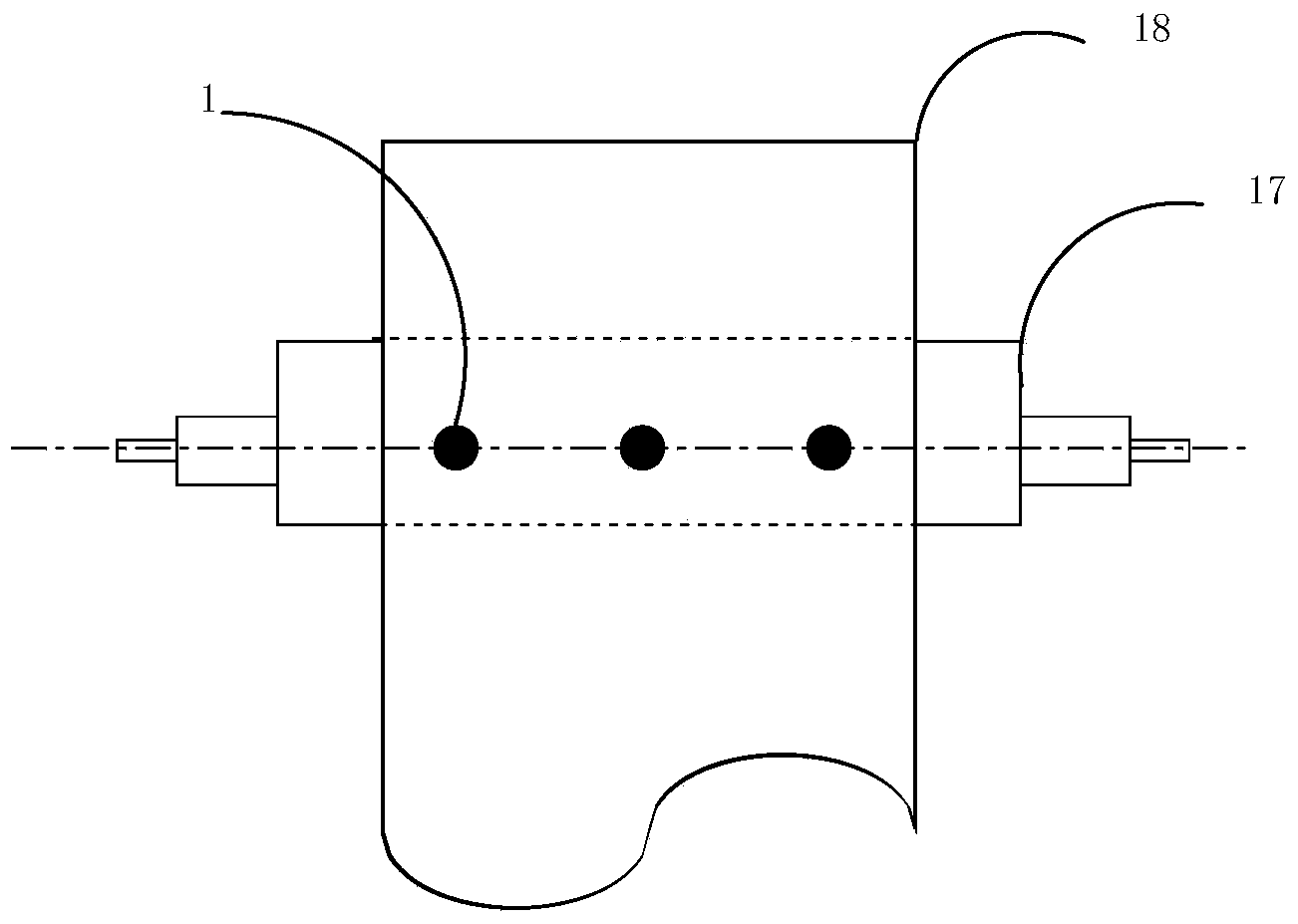

[0025] The present embodiment is the setting of cotton cloth: a kind of system that improves the thermal efficiency of the setting machine, it comprises the cloth guiding roller 17 that is located at the outlet of the shaping machine chain, the cloth 18 is laid on the cloth guiding roller 17, on the cloth guiding roller 17, The position below the cloth 18 is equipped with three cloth moisture content detection heads 1, which are respectively located on the left, middle and right of the cloth 18 plane; it also includes a burner 10 that provides heat to the dry air, and the input end of the burner 10 inputs fresh air and fuel , the output end of the burner 10 is connected to the mixer 11, and the input end of the mixer 11 is also respectively connected to a waste heat recovery heat exchanger 6 and a filter 16, and the input end of the waste heat recovery heat exchanger 6 is respectively connected to a fresh air induced draft fan 7 and exhaust blower 8, the input end of filter 16 ...

Embodiment 2

[0033]The present embodiment is the setting of cotton cloth: a kind of system that improves the thermal efficiency of the setting machine, it comprises the cloth guiding roller 17 that is located at the outlet of the shaping machine chain, the cloth 18 is laid on the cloth guiding roller 17, on the cloth guiding roller 17, The position below the cloth 18 is equipped with three cloth moisture content detection heads 1, which are respectively located on the left, middle and right of the cloth 18 plane; it also includes a burner 10 that provides heat to the dry air, and the input end of the burner 10 inputs fresh air and fuel , the output end of the burner 10 is connected to the mixer 11, and the input end of the mixer 11 is also respectively connected to a waste heat recovery heat exchanger 6 and a filter 16, and the input end of the waste heat recovery heat exchanger 6 is respectively connected to a fresh air induced draft fan 7 and exhaust blower 8, the input end of filter 16 i...

Embodiment 3

[0041] The present embodiment is the setting of cotton cloth: a kind of system that improves the thermal efficiency of the setting machine, it comprises the cloth guiding roller 17 that is located at the outlet of the shaping machine chain, the cloth 18 is laid on the cloth guiding roller 17, on the cloth guiding roller 17, The position below the cloth 18 is equipped with three cloth moisture content detection heads 1, which are respectively located on the left, middle and right of the cloth 18 plane; it also includes a burner 10 that provides heat to the dry air, and the input end of the burner 10 inputs fresh air and fuel , the output end of the burner 10 is connected to the mixer 11, and the input end of the mixer 11 is also respectively connected to a waste heat recovery heat exchanger 6 and a filter 16, and the input end of the waste heat recovery heat exchanger 6 is respectively connected to a fresh air induced draft fan 7 and exhaust blower 8, the input end of filter 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com