Measurement method for transverse vibration measurement system of axial movement rope

A technology of lateral vibration and measurement system, which is applied in the direction of measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of no mobile rope vibration test device, no public report of experimental device, etc., and achieve simple structure and high integration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

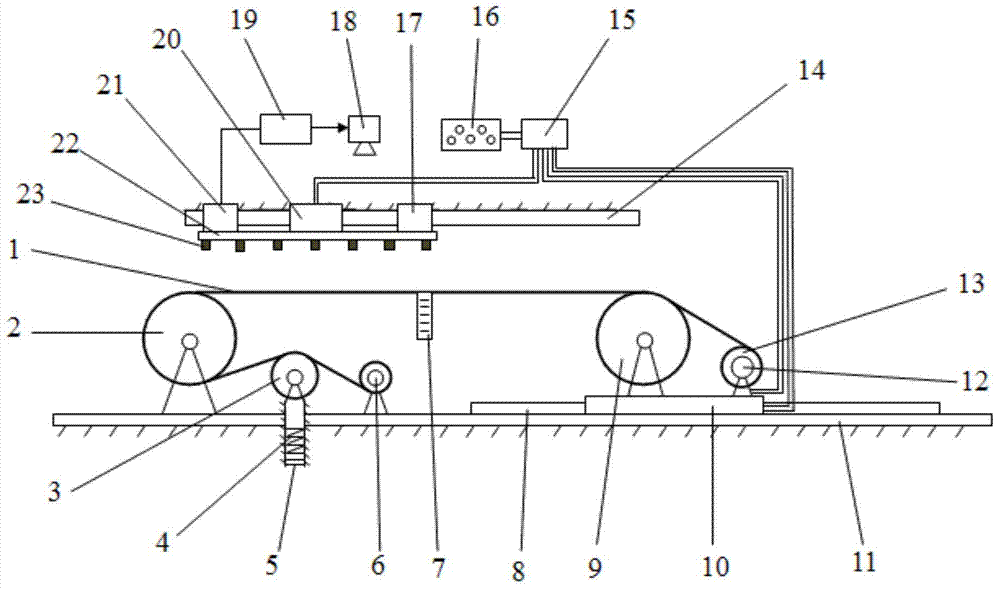

[0026] see figure 1 , the structural form of the axially moving rope lateral vibration measurement system in this embodiment is:

[0027] The wheel train is set, and the wire rope 1 is arranged on the gear train, and the gear train is successively set as the tension pulley 3, the left end guide wheel 2, the right end guide wheel 9 and the reel 13 according to the direction of the wire rope 1 from the end where the wire take-up device 6 is located. The two ends of the wire rope 1 are respectively connected to the wire take-up device 6 and the reel 13; the wire take-up device 6 provides the wire rope recovery force with a coil spring; Displacement scale 7 is set on the long central position; Displacement scale 7 is arranged at the central position of initial rope length, when the initial condition of wire rope lateral vibration is given wire rope center point displacement, the displacement size of this point can be measured, for Numeral Calculations.

[0028] The wire take-up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com