Scanning galvanometer system

A scanning galvanometer system and scanning lens technology, applied in the field of scanning galvanometers, can solve the problems of very high professional requirements for assemblers and difficult installation of 45° lenses, and achieve the effect of improving the accuracy of optical path transmission and improving assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

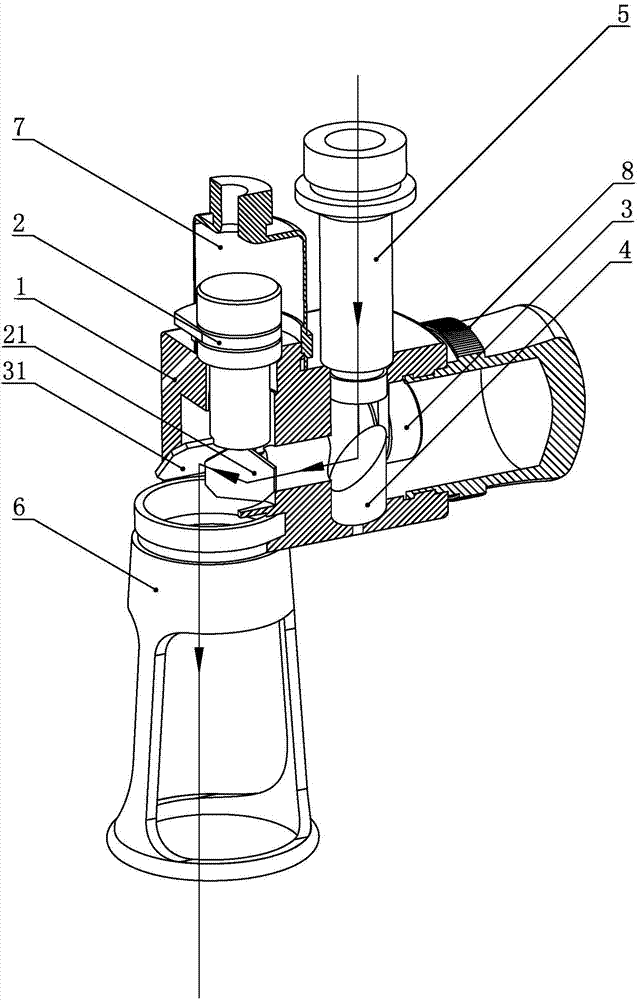

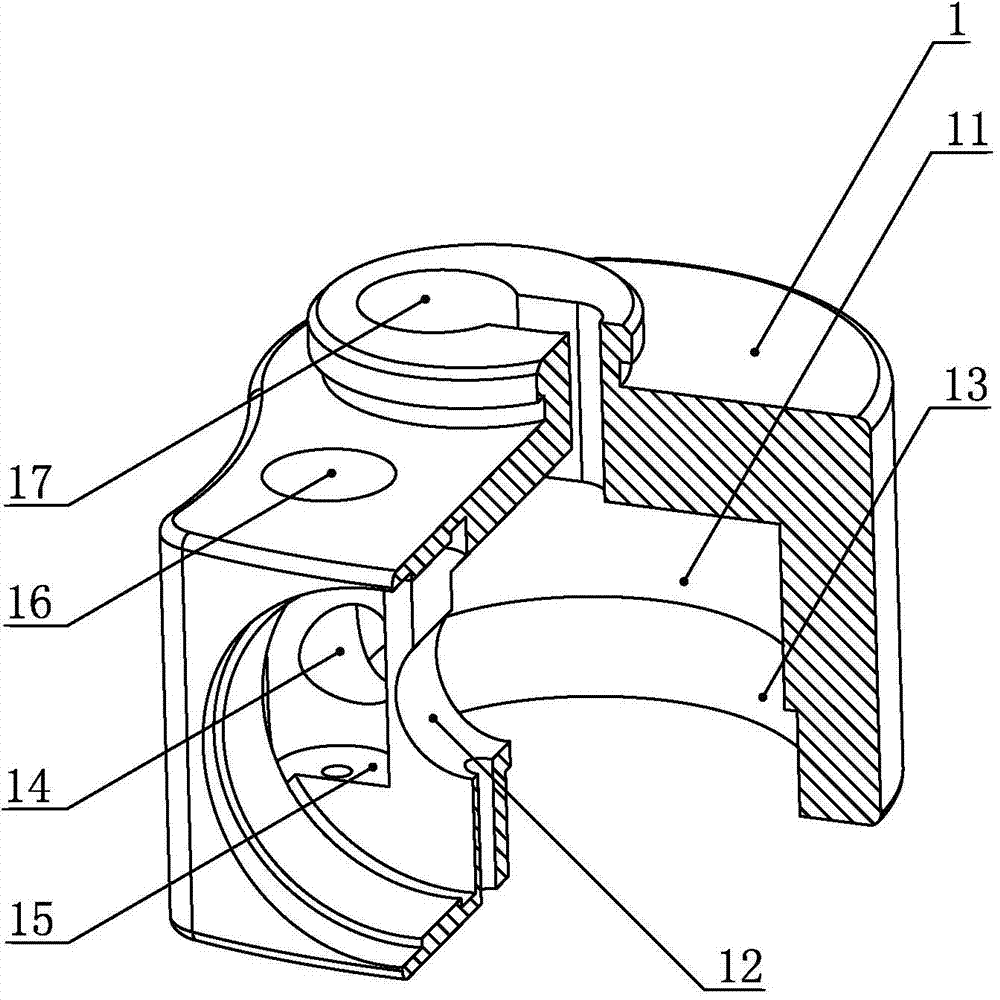

[0023] Such as figure 1 , figure 2 As shown, a scanning galvanometer system includes: a bracket 1, a fixed focus frame 6, an X scanning motor 2, a Y scanning motor 3, a 45° mirror 4, and a light incident sleeve 5;

[0024] The upper end of the bracket 1 is vertically provided with an X scanning motor hole 17 and a light incident sleeve hole 16, the right end is horizontally provided with a Y scanning motor hole 12, and the lower end is vertically provided with a fixed focus frame hole 13; the inside of the bracket 1 also includes an inner cavity 11, The X scanning motor hole 17, the Y scanning motor hole 12 and the fixed focus frame hole 13 penetrate inwardly to the frame inner cavity 11 respectively; an optical path hole is also included, and the axis of the optical path hole 14 intersects the axis of the optical sleeve hole 16 vertically and Parallel to the axis of the Y scanning motor hole 12;

[0025] The X scanning motor 2 includes an X mirror 21, and the X mirror 21 i...

Embodiment 2

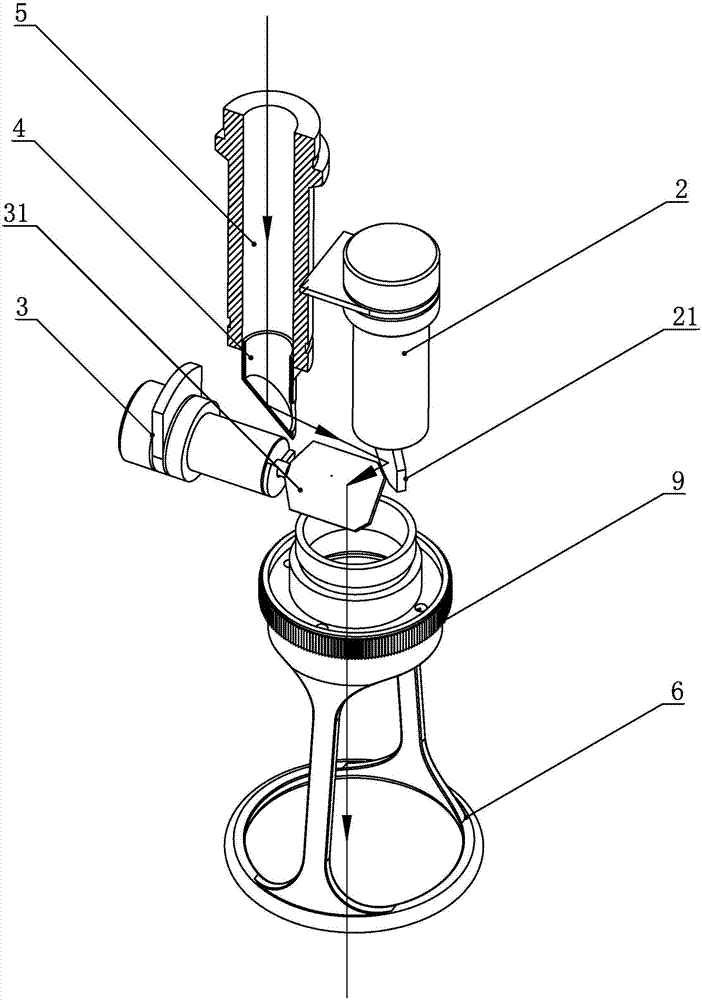

[0031] Such as image 3 , Figure 4 As shown, Embodiment 2 provides another scanning galvanometer system. There are two differences between the scanning galvanometer system provided in this embodiment and the scanning galvanometer system provided in Embodiment 1: First, in this embodiment, the 45° The reflector 4 is a hollow tube body, the 45° reflector 4 upper end is an opening, and the bottom end of the inner wall of the 45° reflector 4 is provided with a reflector that is 45° inclining to the horizontal plane, and the side wall of the 45° reflector 4 is provided with a through hole, and the through hole corresponds to the reflective lens, and the 45 ° reflective mirror 4 is fixedly connected to the bottom of the light incident sleeve 5. Its two, the scanning galvanometer system provided by the present embodiment also includes a scanning lens 9, the upper end of the scanning lens 9 is connected with the fixed-focus frame hole 13 at the lower end of the support 1, and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com