Blast-furnace gas boiler economizer boiling degree on-line monitoring device and method

A blast furnace gas and monitoring device technology, applied in measuring devices, instruments, electrical program control and other directions, can solve problems such as completely accurate judgment results, uneven levels, and hidden dangers in the safe operation of economizers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0074] Embodiment 1 Online monitoring device:

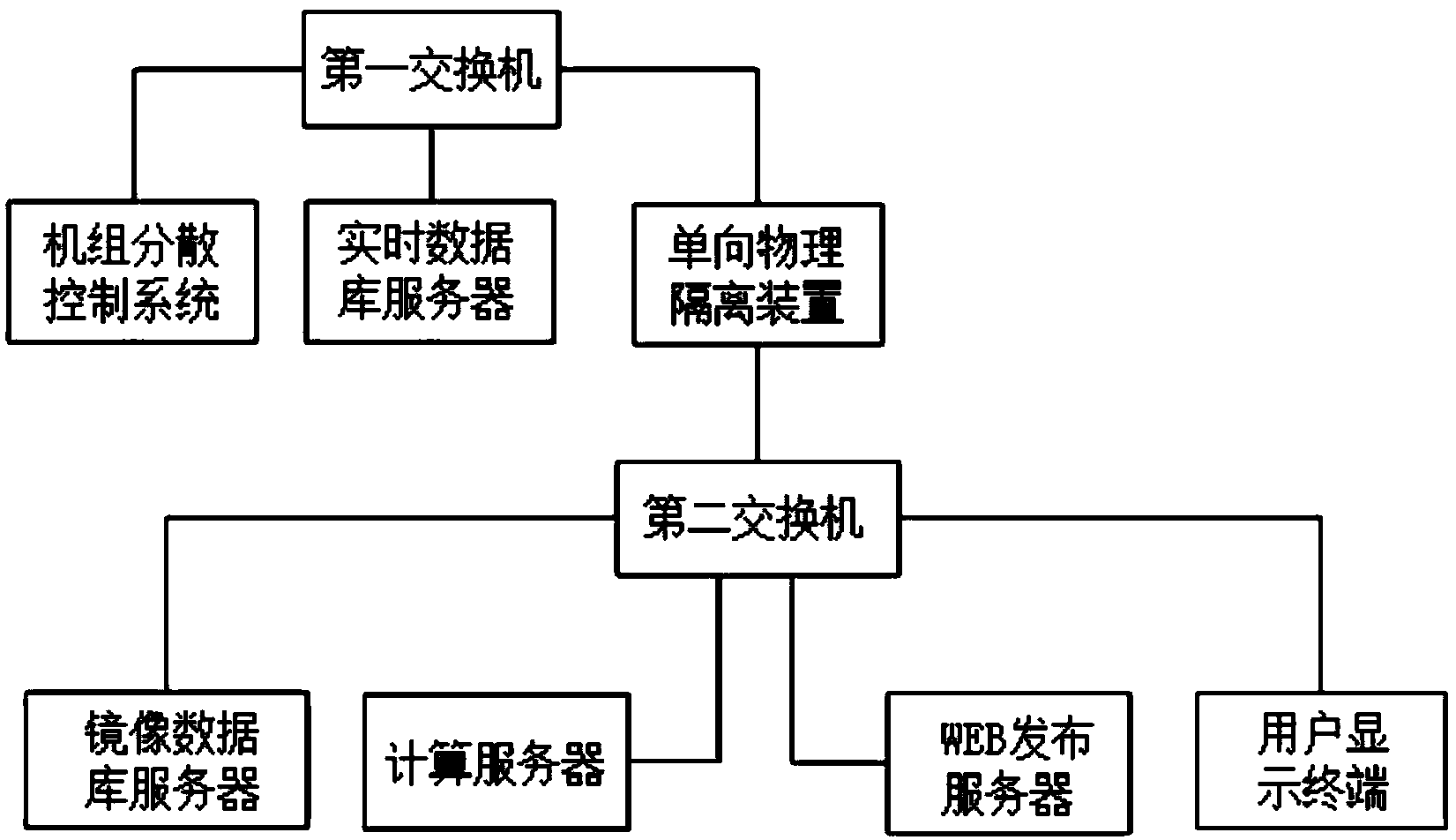

[0075] Such as figure 1 As shown, an on-line monitoring device for boiling degree of a blast furnace gas boiler economizer of the present invention includes a data acquisition unit, a one-way physical isolation device and a data processing unit, and the data acquisition unit and the data processing unit are separated by one-way physical isolation device to connect.

[0076] Wherein, the data acquisition unit includes a unit distributed control system, a real-time database server and a first switch, and the first switch is respectively connected to the unit distributed control system and the real-time database server. The unit distributed control system collects the operation data of the blast furnace gas boiler, and stores the collected operation data in the real-time database server. The operating data collected by the distributed control system of the unit includes the inlet temperature of the flue gas side of the economizer ...

Embodiment approach 2

[0078] Embodiment 2 online monitoring method:

[0079] The invention provides an online monitoring method for the boiling degree of an economizer of a blast furnace gas boiler, and the key points of its design include the following steps:

[0080] Step 1: The unit distributed control system of the data acquisition unit collects the operation data of the blast furnace gas boiler, and stores the operation data in the real-time database server, and the real-time database server sends the received and stored operation data to the mirror database server for storage .

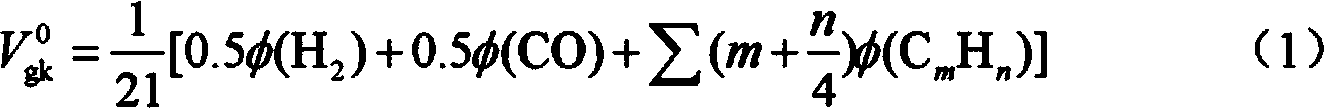

[0081] Step 2: The calculation server of the data processing unit reads the operating data of the blast furnace gas boiler from the mirror database server through the KKS code point number of the measuring point. The read operating data collected by the distributed control system of the unit includes the inlet temperature of the flue gas side of the economizer θ y,in , economizer flue gas side outlet temperature θ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com