(meth) acrylic resin composition

A technology of methyl methacrylate and acrylic acid, applied in the direction of coating, etc., can solve the problems of poor appearance, insufficient weather resistance, and inability to fully suppress thermal coloration of molded products, and achieve the effect of good appearance and excellent injection moldability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

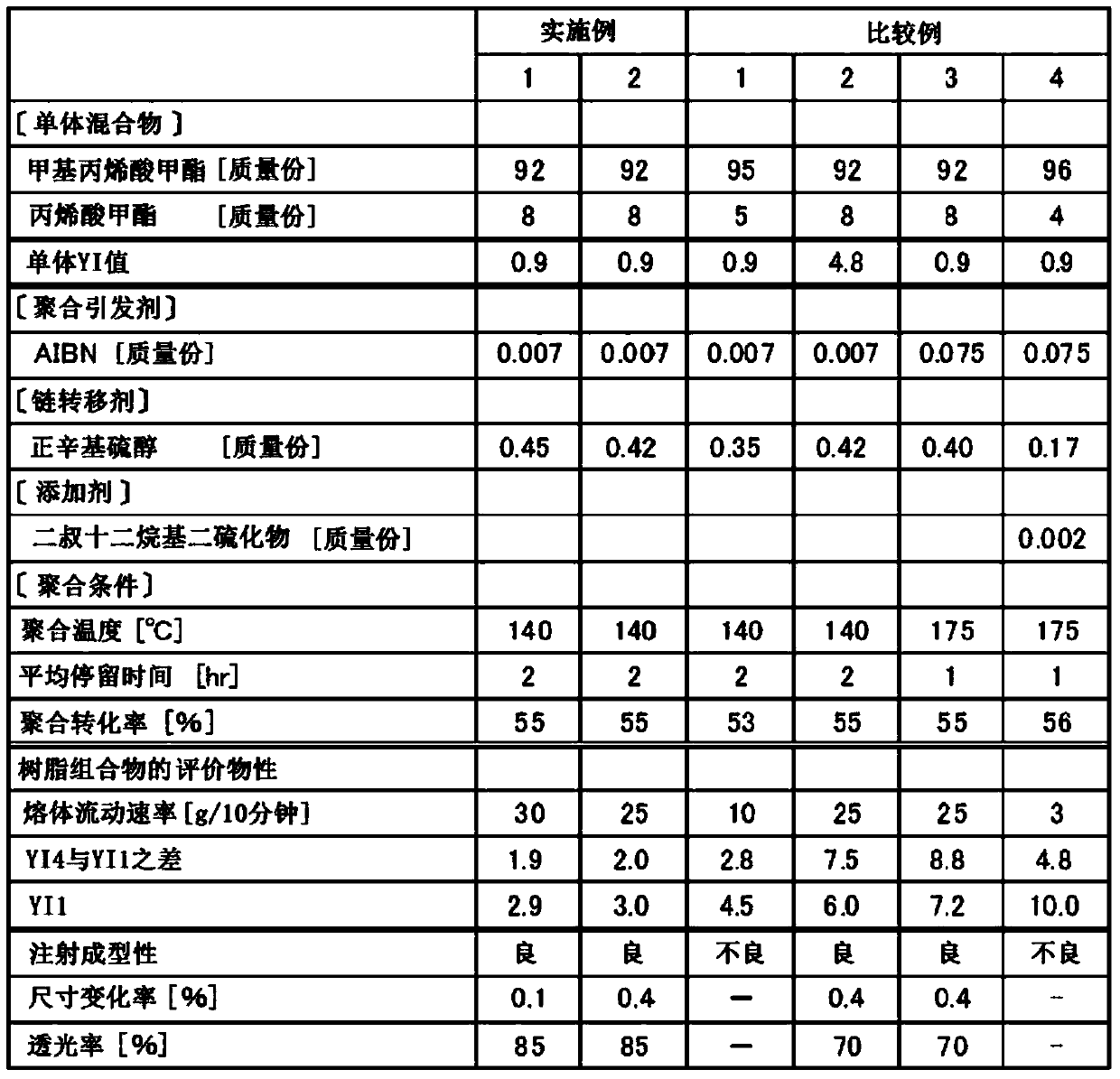

[0109] 92 parts by mass of purified methyl methacrylate and 8 parts by mass of methyl acrylate were added to an autoclave equipped with a stirrer and a sampling tube to prepare a monomer mixture. The yellowness index of the monomer mixture was 0.9. Add 0.007 parts by mass of a polymerization initiator (2,2'-azobis(2-methylpropionitrile (AIBN), dehydrogenation capacity: 1%, 1-hour half-life temperature: 83°C) to the monomer mixture and chain transfer Agent (n-octyl mercaptan) 0.45 mass parts, make it dissolve to obtain raw material liquid. Utilize nitrogen gas to get rid of the oxygen in the manufacturing device.

[0110] A certain amount of the raw material liquid was discharged from the autoclave, supplied at a constant flow rate to a continuous flow tank reactor controlled at a temperature of 140° C. so that the average residence time was 120 minutes, and bulk polymerization was performed. The reaction liquid was separated from the sampling tube of the reactor and measured ...

Embodiment 2

[0113] Except having changed the quantity of n-octyl mercaptan into 0.42 mass parts, the granular (meth)acrylic-type resin composition of this invention was obtained by the method similar to Example 1. Various physical properties of this granular (meth)acrylic resin composition were evaluated by the same method as Example 1. These results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com