Polypropylene resin composition

A technology of polypropylene-based resin and composition, which is applied in the field of polypropylene-based resin composition, which can solve problems such as large temperature dimensional changes, poor installation performance, and poor gap quality, and achieve excellent mechanical properties and excellent injection moldability , excellent dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The preparation of the solid titanium catalyst component (I) can also be carried out in the presence of a known medium as needed. Specific examples of the medium include slightly polar aromatic hydrocarbons such as toluene, and known aliphatic or alicyclic hydrocarbon compounds such as heptane, octane, decane, and cyclohexane. Among them, aliphatic hydrocarbons are preferable.

[0056] As the electron donor component (1) used when forming a solid adduct and a liquid magnesium compound, a known compound capable of dissolving a magnesium compound at a temperature range from room temperature to about 300° C. is preferable, for example, alcohol, Aldehydes, amines, carboxylic acids and their mixtures, etc. Examples of these compounds include compounds described in JP-A-57-63310 and JP-A-5-170843.

[0057] Specific examples of alcohols capable of dissolving magnesium compounds include methanol, ethanol, propanol, butanol, isobutanol, ethylene glycol, 2-methylpentanol, 2-eth...

Embodiment

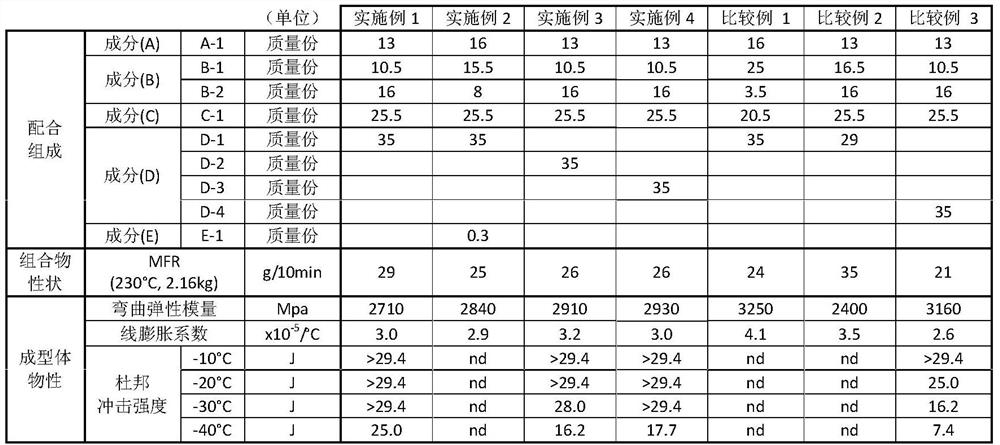

[0163] Hereinafter, the present invention will be described in more detail based on examples, but the present invention is not limited to these examples.

[0164] In Examples and Comparative Examples, measurement and evaluation of various physical properties were performed by the following methods.

[0165] [Melt Flow Rate (MFR) (g / 10min)]

[0166] According to ISO 1133, the measurement was carried out under the conditions of a test load of 2.16 kg and a test temperature of 230°C.

[0167] [intrinsic viscosity [η]]

[0168] About 20 mg of the sample was dissolved in 15 ml of decahydronaphthalene, and the specific viscosity η was measured in an oil bath at 135°C. sp . Add 5 ml of decahydronaphthalene solvent to this decahydronaphthalene solution to dilute it, and then perform the same operation to measure the specific viscosity η sp . Repeat this dilution operation twice again to obtain η when the concentration (C) is extrapolated to 0 sp / C value, as the intrinsic viscos...

manufacture example 1

[0188] [Production Example 1] Preparation of Propylene-Ethylene Block Copolymer (A-1)

[0189] (1) Preparation of solid titanium catalyst components

[0190] 95.2 g of anhydrous magnesium chloride, 442 mL of decane, and 390.6 g of 2-ethylhexanol were heated and reacted at 130°C for 2 hours to form a homogeneous solution, and 21.3 g of phthalic anhydride was added to the solution, and further carried out at 130°C. Stir to mix for 1 hour to dissolve the phthalic anhydride.

[0191] After cooling the homogeneous solution to room temperature, 75 mL of the homogeneous solution was added dropwise to 200 mL of titanium tetrachloride maintained at -20°C over 1 hour. After completion of charging, the temperature of the mixed liquid was raised to 110° C. over 4 hours, and after reaching 110° C., 5.22 g of diisobutyl phthalate (DIBP) was added, and the temperature was kept under stirring for 2 hours.

[0192] After completion of the 2-hour reaction, the solid portion was collected by h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com