Water absorption coating, preparation method and coating method

A water absorption and coating technology, applied in polyester coatings, polyamide coatings, lignin coatings, etc., can solve the problems of affecting the air circulation on the surface of the heat exchanger, the frost suppression effect is not obvious, and the impact resistance is poor. The cream effect is obvious, the frost suppression effect is improved, and the filling amount is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 The making of polyacrylic acid water-absorbing resin

[0040] Add water, potassium hydroxide and sodium hydroxide to a reactor with a reflux condenser and a dropping funnel nitrogen conduit, and add acrylic acid and N,N'-methylenebisacrylamide under the condition of feeding nitrogen, while Hydroxypropyl methacrylate was added while stirring, keeping the temperature at 40°C. Add acrylamide, add ammonium persulfate initiator and sodium bisulfite in 4 times. It was heated to 60°C and left to stand for 6 hours to carry out a polymerization reaction. After the polymerization reaction, the mixture changes from a white turbid gel to a transparent gel, is cooled and vacuum dehydrated, and then vacuum dried, and the product is ground to obtain a polyacrylic acid water-absorbing resin with a particle size below 0.025 mm.

Embodiment 2

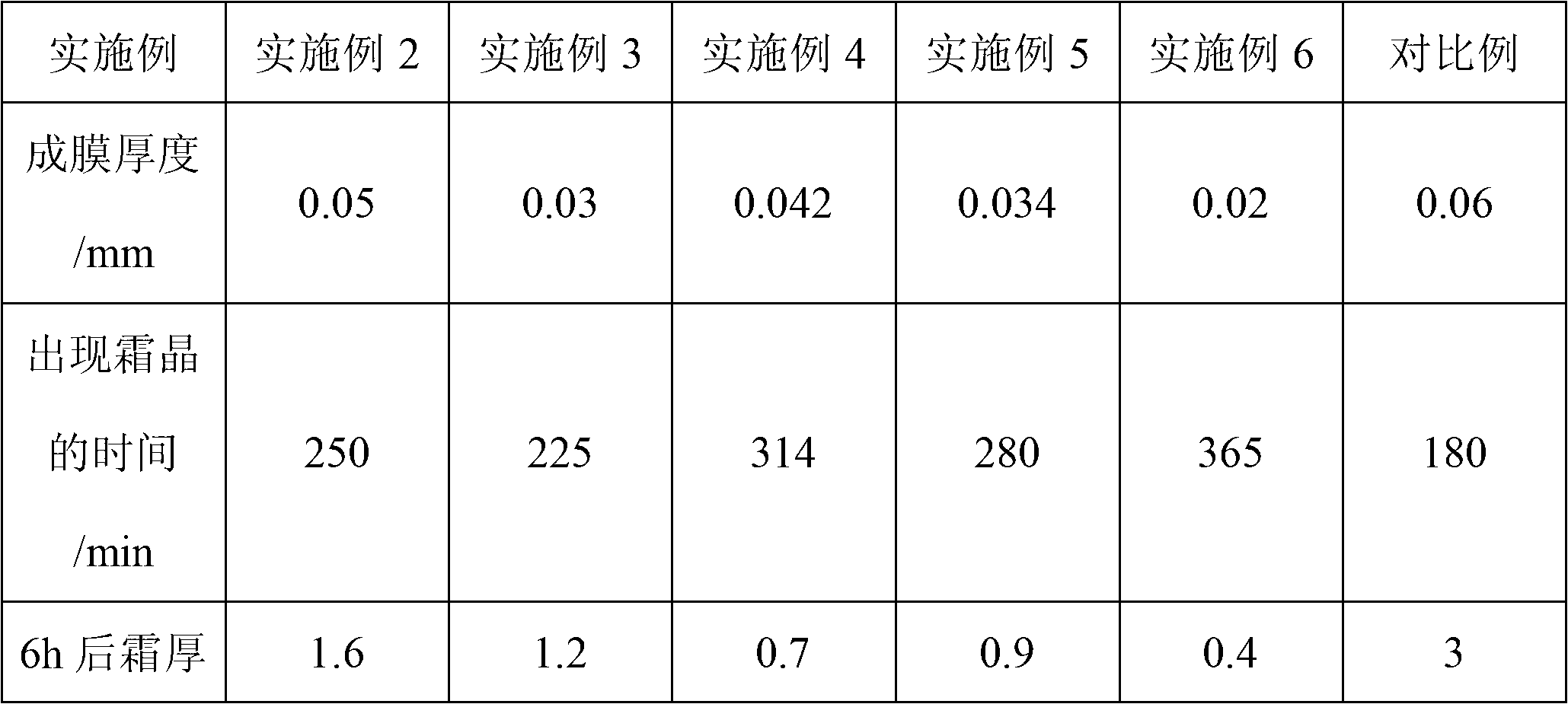

[0041] The preparation of embodiment 2 water-absorbent coatings

[0042] First prepare raw materials according to the following parts by weight: polyacrylic acid water-absorbing resin 8; acrylic resin 20; sodium chloride crystal particles 20; industrial hemp stalk core powder 22; viscosity regulator 5; Stir evenly; add polyacrylic acid water-absorbing resin, stir evenly; then add industrial hemp stalk core powder, stir evenly; then add acrylic resin, viscosity modifier, sodium chloride crystal particles, stir evenly, and filter with a 40-100 mesh screen ,Package.

[0043] The auxiliary agent is as follows: the dispersant is sodium hexametaphosphate, the defoamer is tributyl phosphate, the plasticizer is dibutyl phthalate, the retarder is citric acid, and the expansion The inhibitor is alum.

[0044] The solvent of the present embodiment is propylene glycol butyl ether.

Embodiment 3

[0045] The preparation of embodiment 3 water-absorbent coatings

[0046] First prepare raw materials according to the following parts by weight: polyacrylic acid water-absorbing resin and polyamide-6632; polyurethane 12; sodium chloride, potassium chloride crystal particles 24; industrial hemp stalk powder 15; viscosity regulator 18; After the conventional amount of additives, stir well; then add polyacrylic acid water-absorbing resin and polyamide-66, stir well; then add industrial hemp stalk powder, stir well; then add acrylic resin, viscosity modifier, sodium chloride, chlorine Potassium chloride crystal particles, stirred evenly, filtered with a 40-100 mesh screen, and packaged.

[0047] The auxiliary agent is as follows: the dispersant is sodium hexametaphosphate, the defoamer is tributyl phosphate, the plasticizer is dibutyl phthalate, the retarder is citric acid, and the expansion The inhibitor is alum.

[0048] The solvent of this embodiment is cyclohexanone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com