Processing method of high-intensity explosion-proof glass

A technology of explosion-proof glass and processing method, which is applied in the processing field of glass, can solve the problems of user injury, insufficient safety performance, easy breakage, etc., and achieve the effects of improving mechanical resistance, avoiding explosion, and improving surface impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

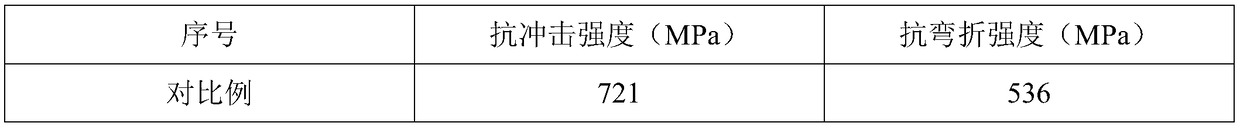

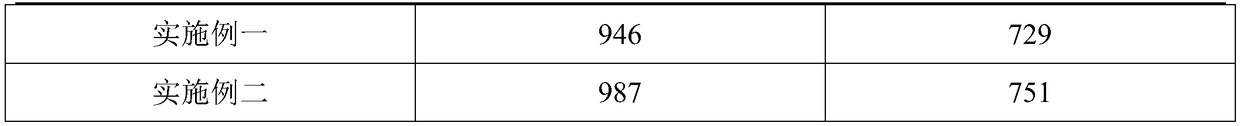

Examples

Embodiment 1

[0039] Embodiment one, comprises the following steps:

[0040] A, prepare two glass substrates, the thickness of the glass substrates is 2mm, each glass substrate is ultrasonically cleaned and heated and dried;

[0041] B. Evaporate graphene on both surfaces of each glass substrate to form reinforcement layers on both sides;

[0042] C. Sputtering titanium dioxide on one of the reinforcing layers of each glass substrate to form an anti-fouling and heat-insulating layer;

[0043] D. Put two glass substrates into the heating furnace, heat at 500°C for 1.5h, then raise the temperature to 650°C for 0.5h, then cool down to 35°C at 9°C / min;

[0044] E. Evenly print UV glue on the reinforcement layer on the side away from the anti-pollution heat insulation layer of each glass substrate, and then cure the UV glue through a UV curing lamp to form a number of unconnected buffer bumps;

[0045] F. Place two glass substrates in parallel, set the buffer bumps of the two glass substrates ...

Embodiment 2

[0048] Embodiment two, comprises the following steps:

[0049] A, prepare two glass substrates, the thickness of the glass substrates is 2mm, each glass substrate is ultrasonically cleaned and heated and dried;

[0050] B. Evaporate graphene on both surfaces of each glass substrate to form reinforcement layers on both sides;

[0051] C. Sputtering titanium dioxide and indium tin oxide on one of the reinforcement layers of each glass substrate to form an anti-pollution and heat insulation layer, the mass ratio of carbon dioxide to indium tin oxide is 1:1;

[0052]D. Put two glass substrates into the heating furnace, heat at 520°C for 1.8h, then raise the temperature to 670°C for 0.8h, then cool down to 40°C at 8°C / min;

[0053] E. Evenly print UV glue on the reinforcement layer on the side away from the anti-pollution heat insulation layer of each glass substrate, and then cure the UV glue through a UV curing lamp to form a number of disconnected buffer bumps;

[0054] F. Pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com