High-temperature-resistant wood floor nano adhesive and preparation method thereof

A wood floor, high temperature resistance technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc. The effect of improving peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

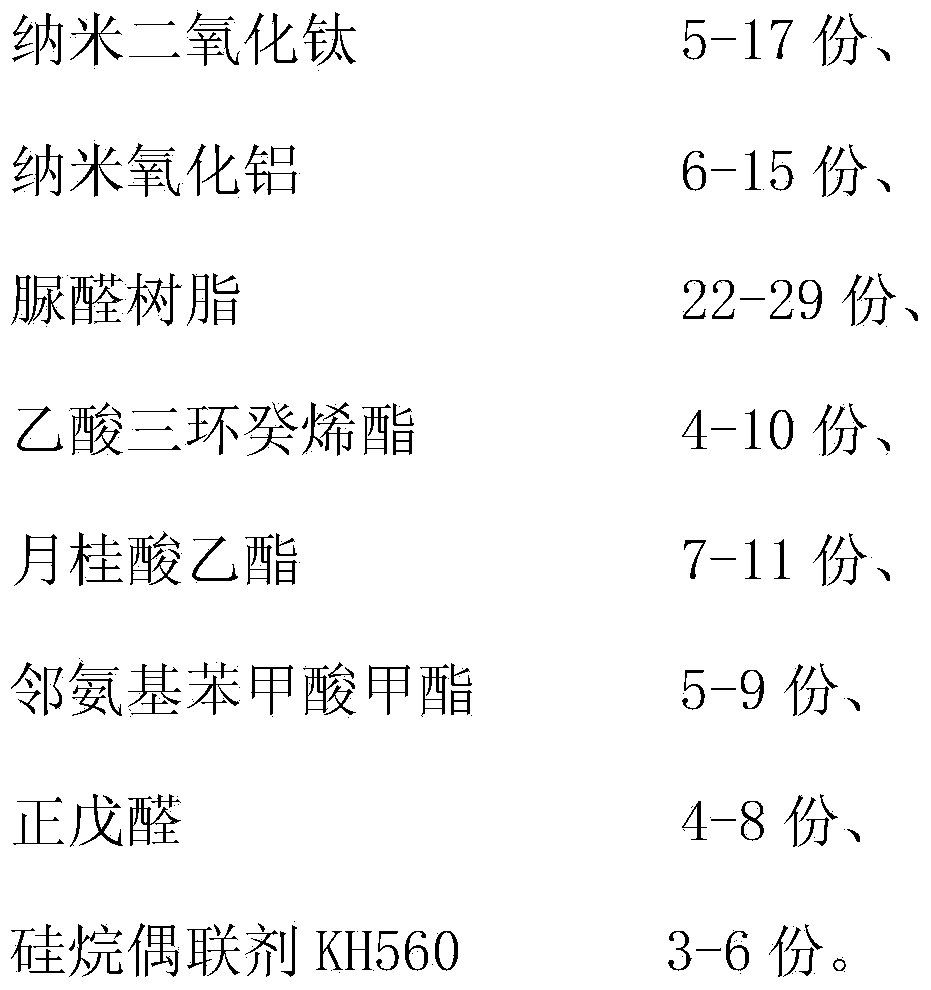

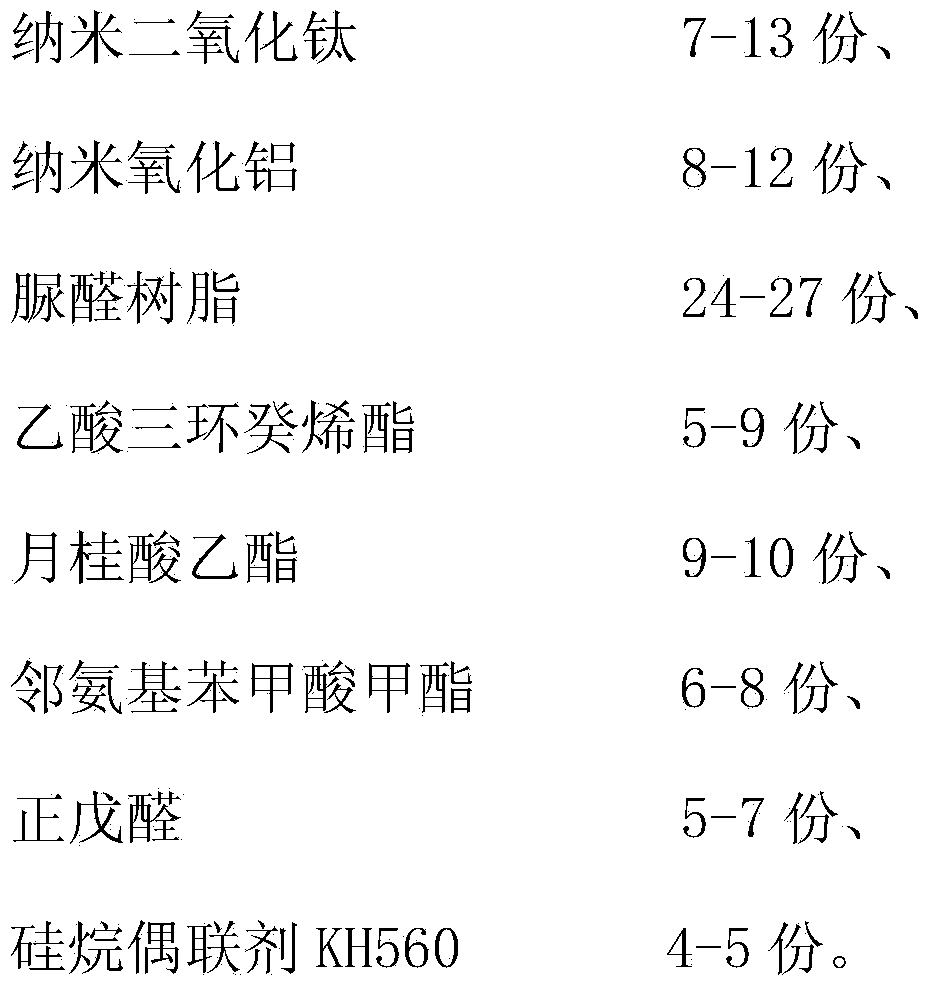

Method used

Image

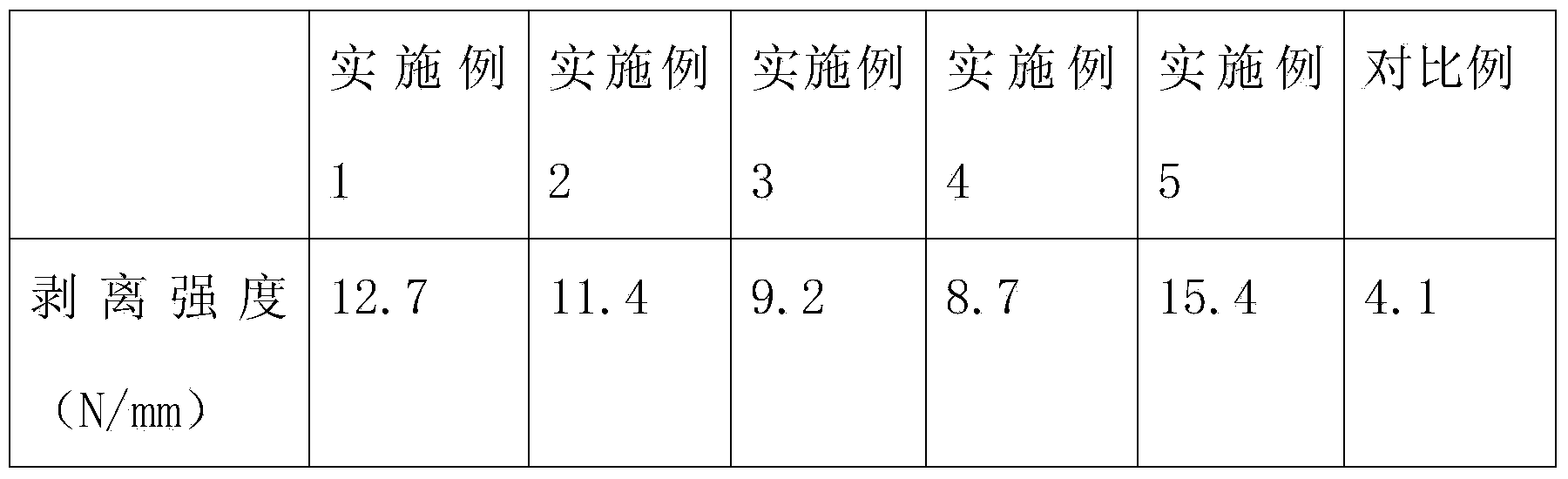

Examples

Embodiment 1

[0018] (1) Take 7 parts by weight of nano-titanium dioxide and 12 parts of nano-alumina, and mix the above two nano-compounds uniformly to form A powder; (2) set the temperature to 84 ° C, add 24 parts of urea-formaldehyde resin, 9 parts of tricyclodecenyl acetate, 9 parts of ethyl laurate, and 8 parts of methyl anthranilate, while adding the above-mentioned ingredients, carry out mechanical stirring, the stirring speed is 160r / min, and the stirring time is 45min; ( 3) Raise the temperature of the mixture in step (2) to 95°C, then add 5 parts of n-valeraldehyde, 5 parts of silane coupling agent KH560, and A powder prepared in step (1), and then mix and stir until uniform For the preparation of high temperature resistant wooden floor nano-adhesive.

Embodiment 2

[0020] (1) Take nano-titanium dioxide by weight as 13 parts, nano-alumina as 8 parts, mix the above two nano-compounds uniformly, be A powder; (2) set the temperature to 65 ° C, add urea-formaldehyde resin to 27 parts, There are 5 parts of tricyclodecenyl acetate, 10 parts of ethyl laurate, and 6 parts of methyl anthranilate. When adding the above ingredients, mechanical stirring is carried out, the stirring speed is 120r / min, and the stirring time is 90min; ( 3) Raise the temperature of the mixture in step (2) to 88°C, then add 7 parts of n-valeraldehyde, 4 parts of silane coupling agent KH560, and A powder prepared in step (1), and then mix and stir until uniform For the preparation of high temperature resistant wooden floor nano-adhesive.

Embodiment 3

[0022] (1) Take 5 parts of nano-titanium dioxide and 15 parts of nano-alumina by weight, and mix the above two nano-compounds evenly to form A powder; (2) Set the temperature to 65 ° C, add 29 parts of urea-formaldehyde resin, tricyclic acetic acid 10 parts of decenyl esters, 7 parts of ethyl laurate, 9 parts of methyl anthranilate, carry out mechanical stirring while adding above-mentioned composition, stirring speed is 120r / min, and stirring time is 90min; (3) step (2 ) to 88°C, then add 4 parts of n-valeraldehyde, 6 parts of silane coupling agent KH560, and A powder prepared in step (1), then mix and stir, and after stirring evenly, the prepared high temperature resistant Nano-adhesives for wooden floors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com