A kind of high temperature resistant wooden floor nano-adhesive and preparation method thereof

A wooden floor and high temperature resistant technology, which is applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of poor high temperature resistance of adhesives, achieve high temperature resistance, improve peel strength, and improve The effect of the sticky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

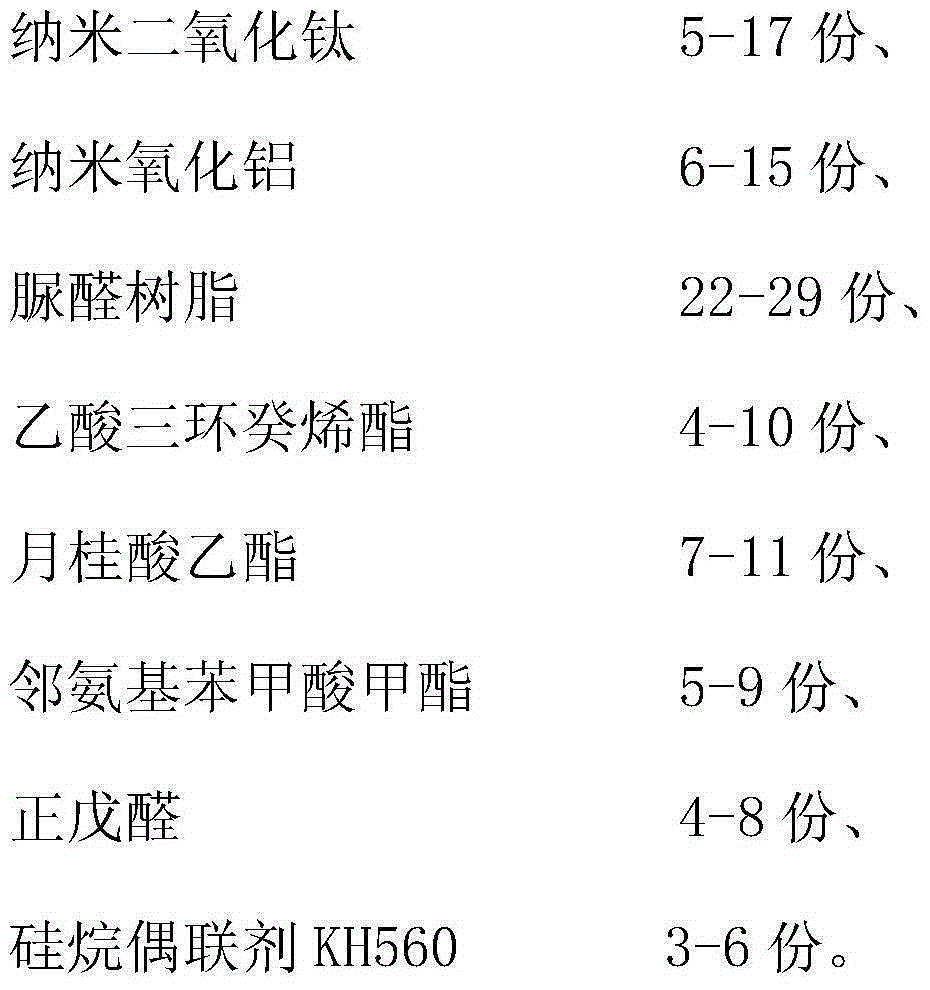

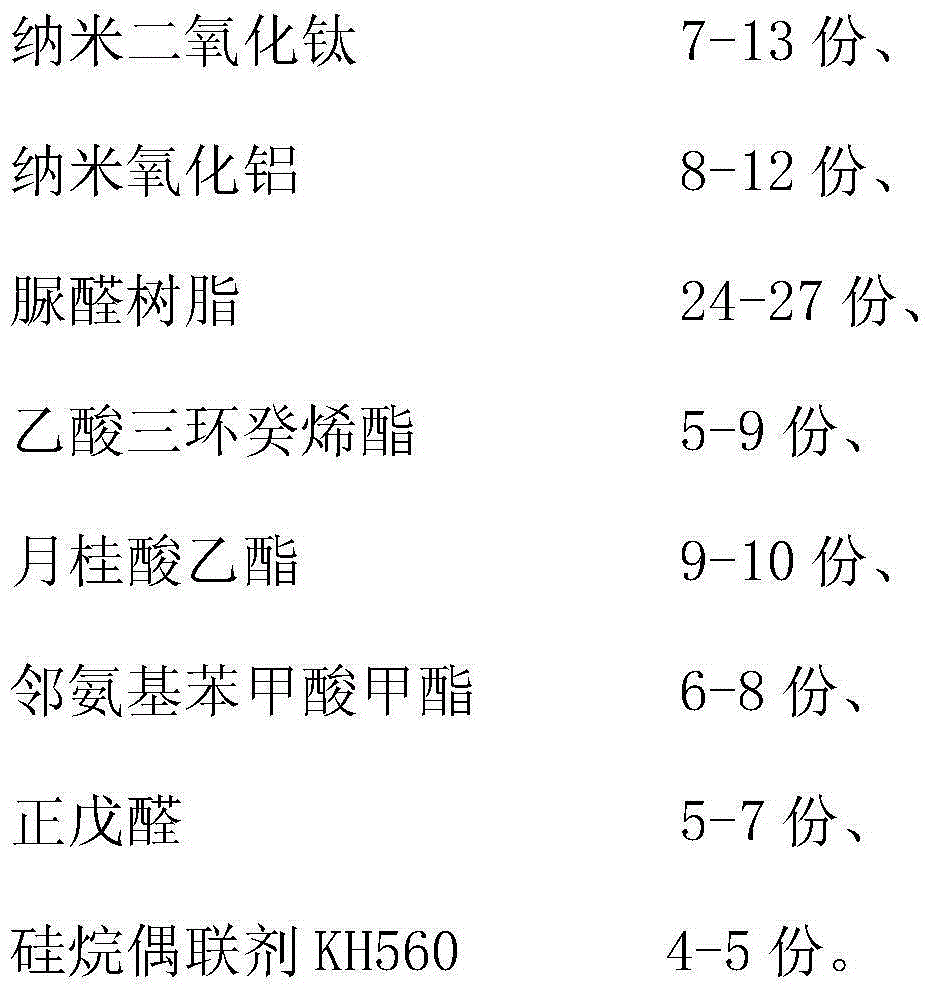

Method used

Image

Examples

Embodiment 1

[0018] (1) Take 7 parts by weight of nano-titanium dioxide and 12 parts of nano-alumina, and mix the above two nano-compounds uniformly to form A powder; (2) set the temperature to 84 ° C, add 24 parts of urea-formaldehyde resin, 9 parts of tricyclodecenyl acetate, 9 parts of ethyl laurate, and 8 parts of methyl anthranilate, while adding the above-mentioned ingredients, carry out mechanical stirring, the stirring speed is 160r / min, and the stirring time is 45min; ( 3) Raise the temperature of the mixture in step (2) to 95°C, then add 5 parts of n-valeraldehyde, 5 parts of silane coupling agent KH560, and A powder prepared in step (1), and then mix and stir until uniform For the preparation of high temperature resistant wooden floor nano-adhesive.

Embodiment 2

[0020] (1) Take nano-titanium dioxide by weight as 13 parts, nano-alumina as 8 parts, mix the above two nano-compounds uniformly, be A powder; (2) set the temperature to 65 ° C, add urea-formaldehyde resin to 27 parts, There are 5 parts of tricyclodecenyl acetate, 10 parts of ethyl laurate, and 6 parts of methyl anthranilate. When adding the above ingredients, mechanical stirring is carried out, the stirring speed is 120r / min, and the stirring time is 90min; ( 3) Raise the temperature of the mixture in step (2) to 88°C, then add 7 parts of n-valeraldehyde, 4 parts of silane coupling agent KH560, and A powder prepared in step (1), and then mix and stir until uniform For the preparation of high temperature resistant wooden floor nano-adhesive.

Embodiment 3

[0022] (1) Take 5 parts of nano-titanium dioxide and 15 parts of nano-alumina by weight, and mix the above two nano-compounds evenly to form A powder; (2) Set the temperature to 65 ° C, add 29 parts of urea-formaldehyde resin, tricyclic acetic acid 10 parts of decenyl esters, 7 parts of ethyl laurate, 9 parts of methyl anthranilate, carry out mechanical stirring while adding above-mentioned composition, stirring speed is 120r / min, and stirring time is 90min; (3) step (2 ) to 88°C, then add 4 parts of n-valeraldehyde, 6 parts of silane coupling agent KH560, and A powder prepared in step (1), then mix and stir, and after stirring evenly, the prepared high temperature resistant Nano-adhesives for wooden floors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com