Water-saving energy-saving utilizing system for improving septic tank

A septic tank and production system technology, applied in biochemical instruments, biochemical equipment and methods, waste fuel, etc., can solve problems such as septic tank and pipe network blockage, impact on city appearance and environmental sanitation, and discharge of nutrient-rich sewage. To achieve the effect of alleviating water shortage, promoting a virtuous circle, and reducing water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

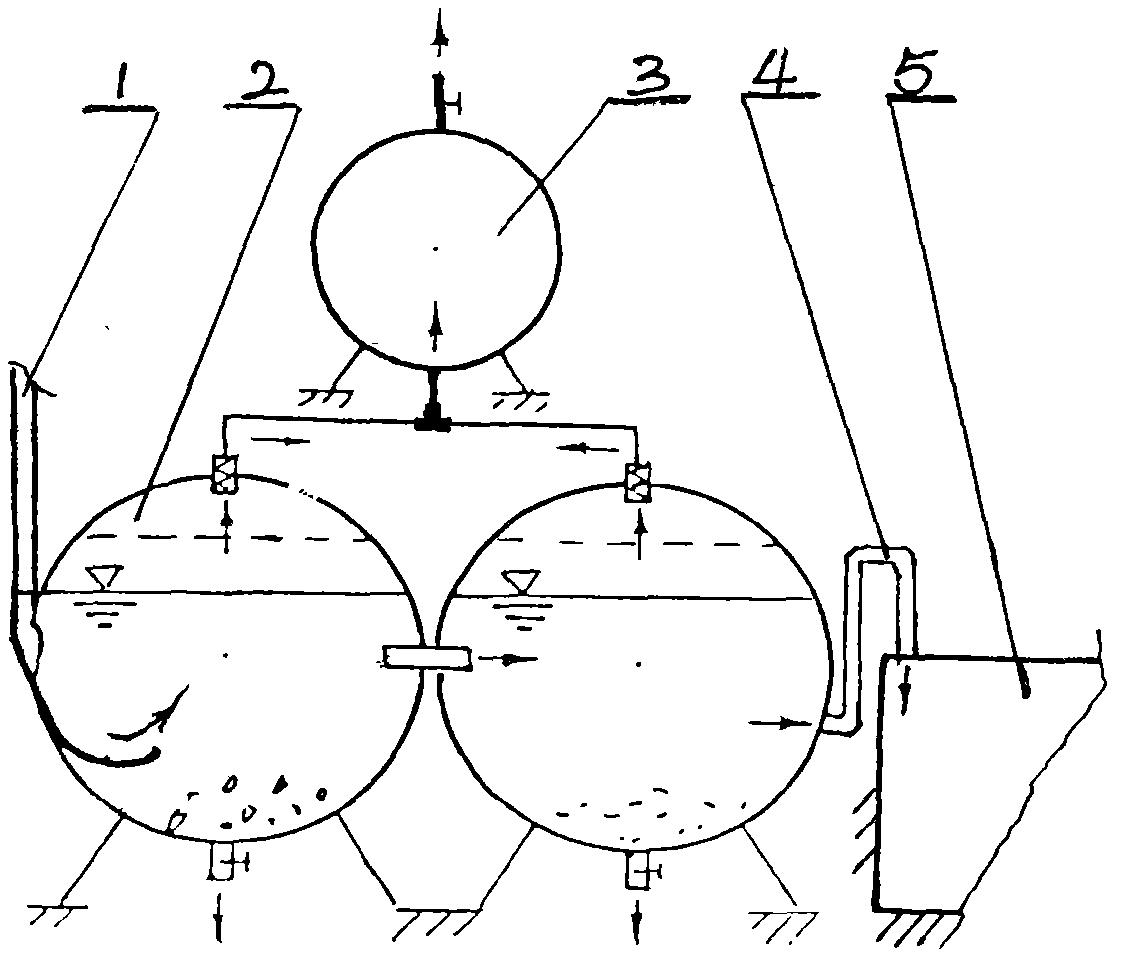

[0009] Such as figure 1 As shown, when the domestic sewage is flushed from the sewage pipe [1] into the fermentation tank in the sewage collection fermentation treatment biogas production system [2], a vortex is formed under the action of gravity acceleration to stir the sewage in the pay tank. Sewage flows into one or more payment tanks in turn through the connecting pipe, which is connected with the biogas tank in the biogas energy collection and utilization system [3] with a safety control valve pipeline, and the biogas produced by the action of anaerobic microorganisms rises to the fermentation tank. The pressure generated in the sewage surface space in the tank increases with the increase of the amount of biogas, forcing the fermented nutrient-rich biogas slurry sewage to flow into the biogas slurry sewage resource collection and utilization system through the hydraulic pressure limit pipe [4] The original septic tanks are used to collect water and store biogas slurry. Si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com