Precious metal-doped WO3 gas-sensitive coating and preparation method thereof

A precious metal and coating technology, which is applied in the direction of metal material coating process, coating, molten spraying, etc., can solve the problems of difficult delivery of solid nano powder, limitation of gas sensitivity characteristics, cumbersome process, etc., and reduce the spray granulation process , Improve the gas sensitivity, the effect of high sensitivity advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

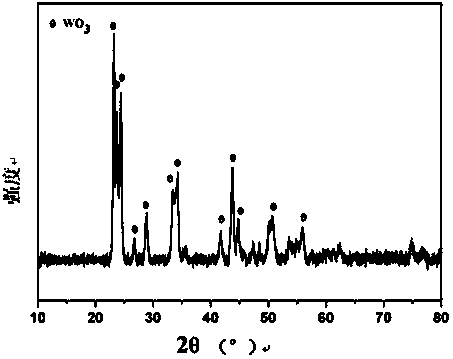

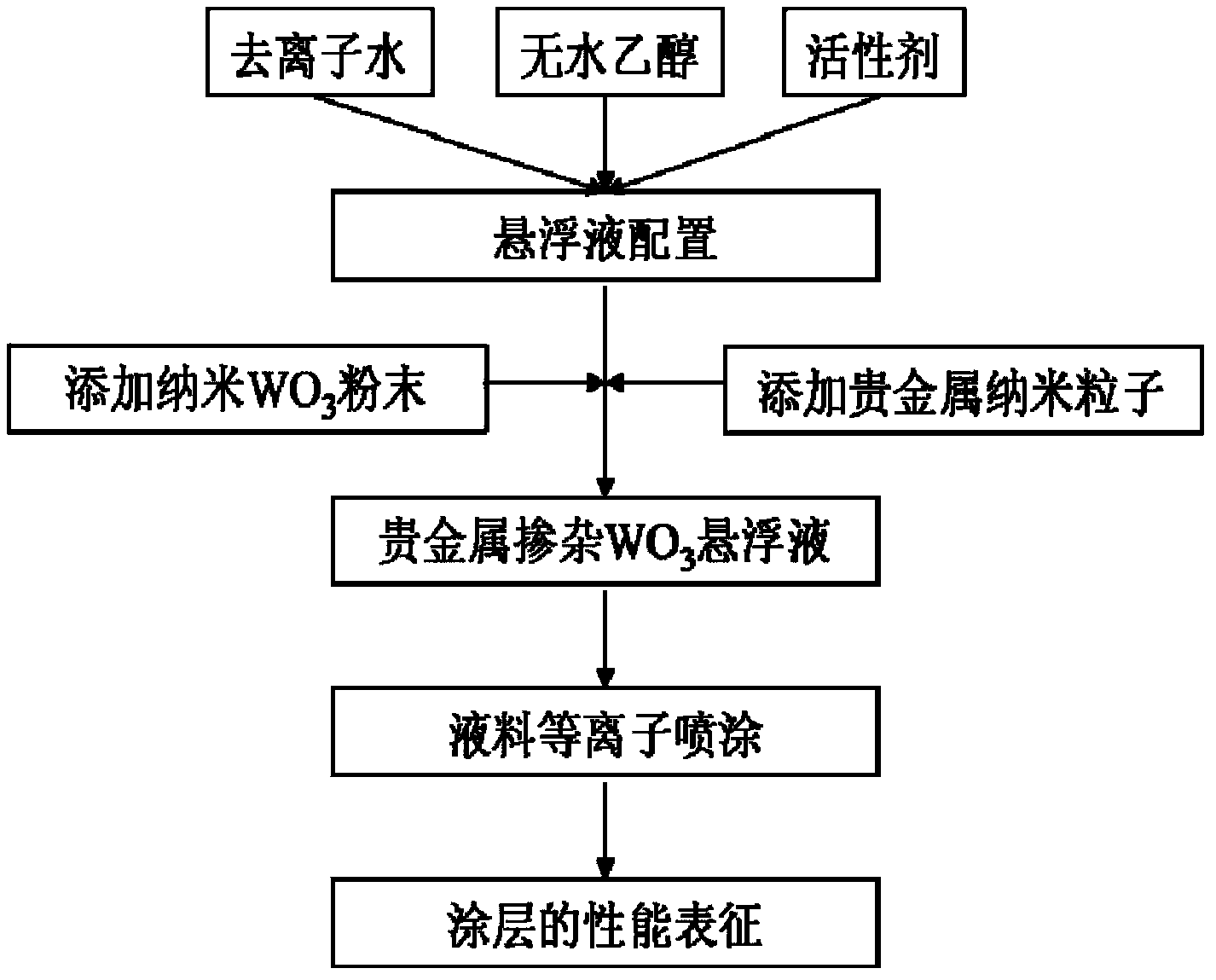

[0032] In this embodiment, the base material is selected as a stainless steel sheet with a thickness of about 2mm, and 0.06wt% nanometer Au is doped with WO on the base. 3 The thickness of the coating prepared by the liquid material is 5 μm, and the coating is submicron-sized WO 3 A porous surface made of stacked crystal grains, where WO 3 The grain size ranges from 50 to 150nm. The ultrathin porous submicron structured Au-doped WO 3 The coating preparation process is as follows figure 1 As shown, the specific preparation method is as follows:

[0033] 1. Mix deionized water and absolute ethanol at a volume ratio of 1:1 to make a solution, add 0.08wt% surfactant polyethylene glycol PEG20000, and commercially available pure WO 3 Nano-powder (particle size: 50nm) and Au nano-powder (particle size: 5-15nm) are added to the prepared solution above, and the WO 3 The solid content is 10wt%, and the Au doping amount is 0.06wt% spray liquid material;

[0034] 2. Clean the substr...

Embodiment 2

[0042] In this embodiment, the base material is selected as a 304 stainless steel sheet with a thickness of about 2mm, and 0.06wt% nanometer Au is doped with WO on the base. 3 The thickness of the coating prepared by the liquid material is 20 μm, and the coating is submicron-sized WO 3 A porous surface made of stacked crystal grains, where WO 3 The grain size ranges from 50 to 250nm. The ultrathin porous submicron structured Au-doped WO 3 The coating preparation process is as follows figure 1 As shown, the specific preparation method is as follows:

[0043] 1. Mix deionized water and absolute ethanol at a volume ratio of 1:2 to make a solution, add 0.10wt% surfactant polyethylene glycol PEG20000, and commercially available pure WO 3 Nano-powder (particle size: 50nm) and Au nano-powder (particle size: 5-15nm) are added to the prepared solution above, and the WO 3 The solid content is 15wt%, the Au doping amount is the spraying liquid material of 0.06wt%;

[0044] 2. Clean...

Embodiment 3

[0052] In this embodiment, the base material is selected to be Al with a thickness of about 2 mm. 2 o 3 Ceramic sheet, 0.012wt% nano-Pt doped WO on the substrate 3 The thickness of the coating prepared by the liquid material is 15 μm, and the coating is submicron-sized WO 3 A porous surface made of stacked crystal grains, where WO 3 The grain size ranges from 50 to 250nm. The ultrathin porous submicron-structured Pt-doped WO 3 The coating preparation process is as follows figure 1 As shown, the specific preparation method is as follows:

[0053] 1. Mix deionized water and absolute ethanol at a volume ratio of 1:4 to make a solution, add 0.08wt% surfactant polyammonium methacrylate, and commercially available pure WO 3 Nano-powder (particle size: 50nm) and Pt nano-powder (particle size: 5-10nm) are added to the prepared solution above, and the WO 3 Solid content is 10wt%, and the spraying liquid material that Pt doping amount is 0.012wt%;

[0054] 2. Clean the substrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com