Oil tube hydraulic lifting device and application method

A lifting device and tubing technology, which is applied in the direction of drill pipe, casing, earthwork drilling, etc., can solve the problems of low work efficiency, poor personnel safety, and high labor intensity of workers, so as to reduce labor intensity, ensure safe production, The effect of improving the status quo of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

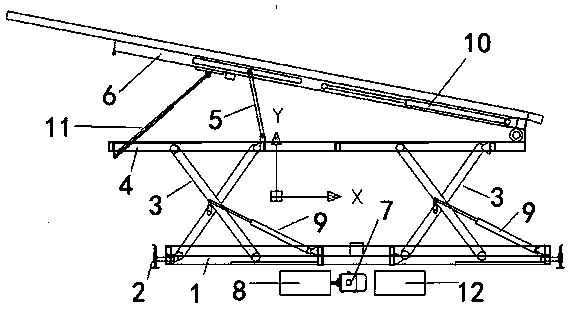

[0017] An oil pipe hydraulic lifting device mainly consists of three parts: a machine body, a hydraulic system and a control system.

[0018] The machine body includes five components including machine base 1, machine base legs 2, cross-shear support 3, lifting platform 4, diagonal brace 5, and telescopic slideway 6; the hydraulic system includes hydraulic pump station 7, control valve 8, and lifting cylinder 9. It is composed of telescopic oil cylinder 10 and inclined extension oil cylinder 11; the control system is composed of power control cabinet 12 and so on.

[0019] combined with figure 1 The structural schematic diagram of the oil pipe hydraulic lifting device further describes the present invention in detail.

[0020] It is mainly composed of three parts: body, hydraulic system and control system. The machine body includes five components including machine base 1, machine base legs 2, cross-shear support 3, lifting platform 4, diagonal brace 5, and telescopic slidew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com