Connection of adjustment actuator with centre valve system for dry belt-type transmission element

A technology of actuators and camshaft adjusters, which is applied in the direction of engine components, machines/engines, valve devices, etc., can solve the problems of difficult stretching and adjustment of actuator connection damage, etc., to achieve direct connection, reduce component complexity, and high-efficiency movement The effect of decoupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

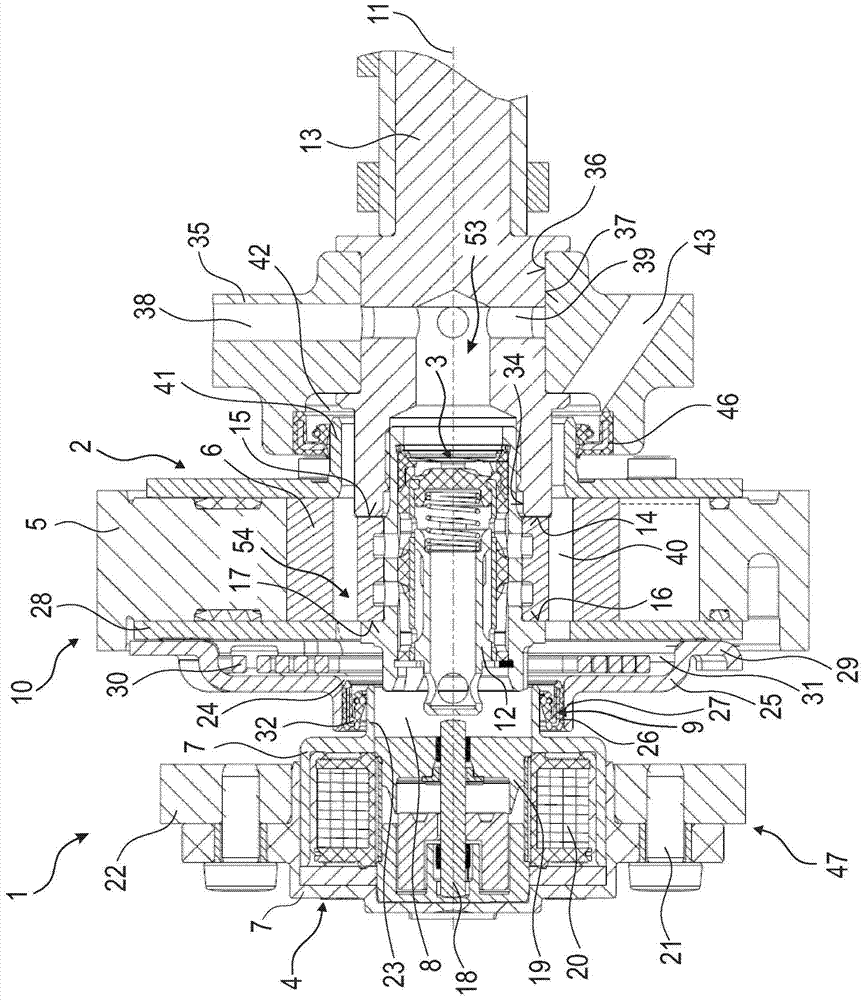

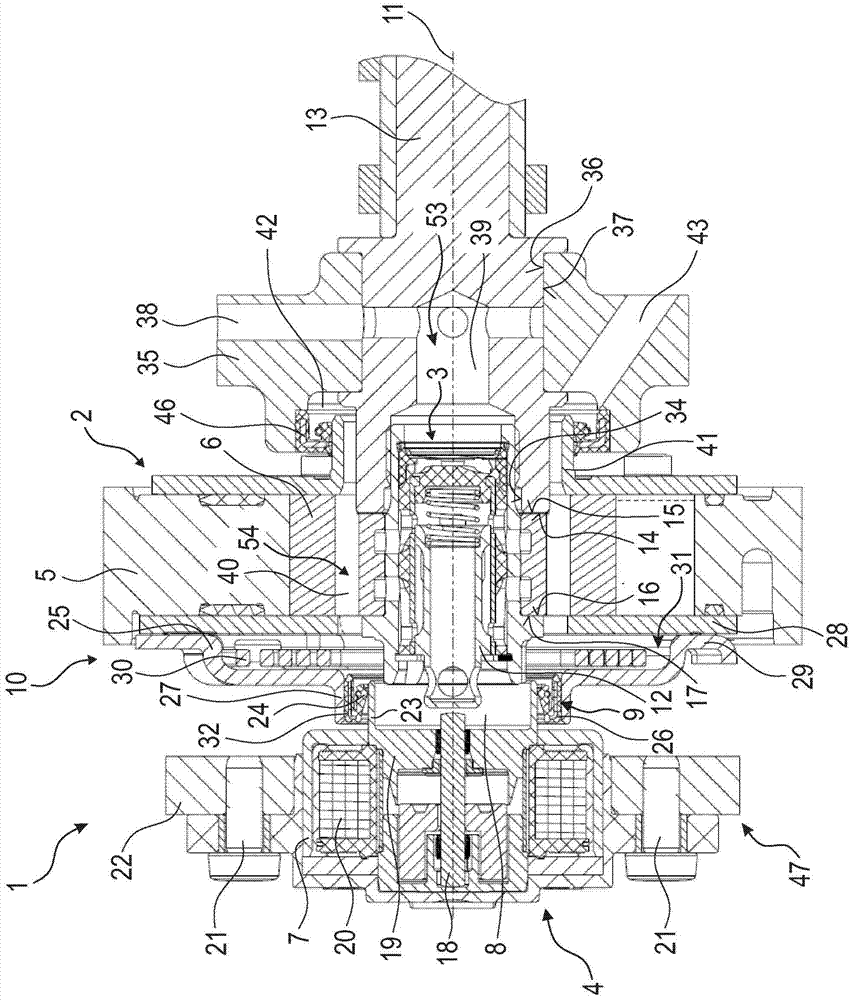

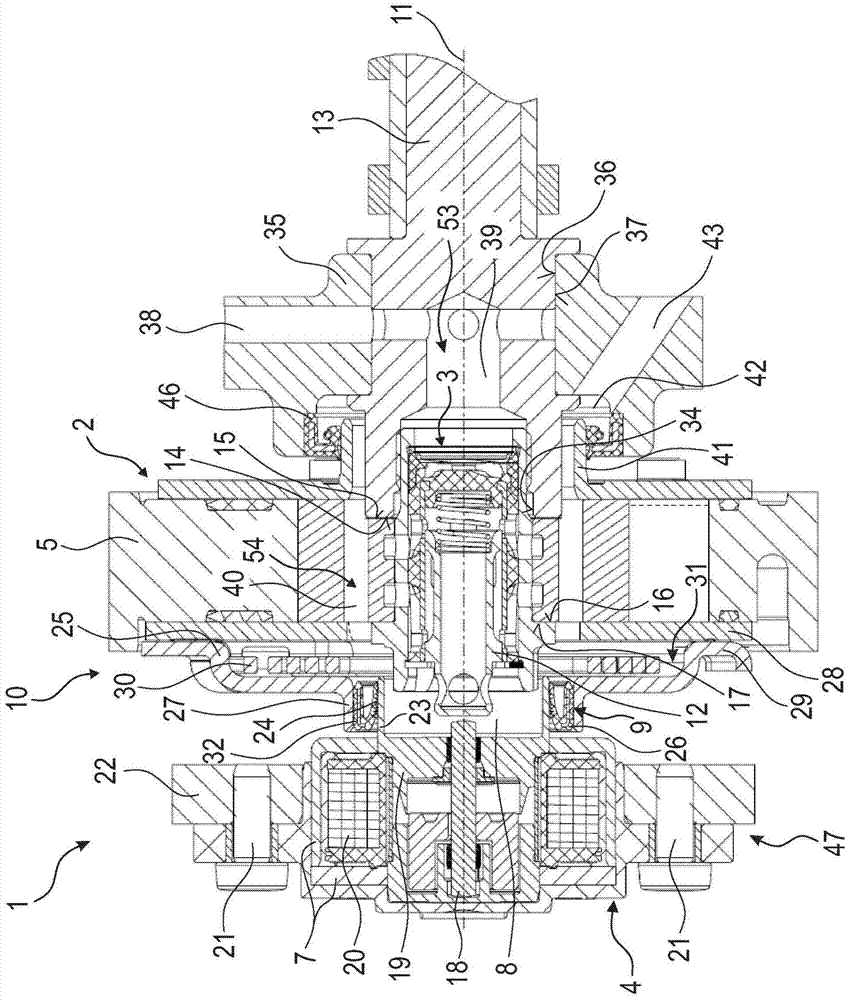

[0060] exist Figure 1 to Figure 16 There are different embodiments of the assembly 1 according to the invention, which can also be referred to as a camshaft adjustment assembly, a camshaft adjustment device or a camshaft adjustment system. In all these figures, the assembly 1 is shown in longitudinal section, wherein an axis of rotation 11 of the assembly lies in the cutting plane, about which the assembly rotates, at least in the operating state. The assembly 1 can be installed in the drive system of a motor vehicle (eg passenger car, van or bus) and can be connected to the camshaft 13 and the crankshaft of an internal combustion engine (eg gasoline or diesel engine). The assembly 1 comprises a camshaft adjuster 2 which is basically constructed and operated according to a camshaft adjuster / device (as it is known from WO 03 / 085238 A1) for varying the control timing of the gas exchange valves of an internal combustion engine . A camshaft adjuster 2 of the type according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com