A two-stage linkage vehicle exhaust temperature difference power generation system

A technology of thermoelectric power generation and automobile exhaust, applied in the direction of generators/motors, electrical components, engine components, etc., can solve the problems of low power generation and conversion efficiency, unstable voltage/current output, etc., and achieve the effect of improving the overall power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

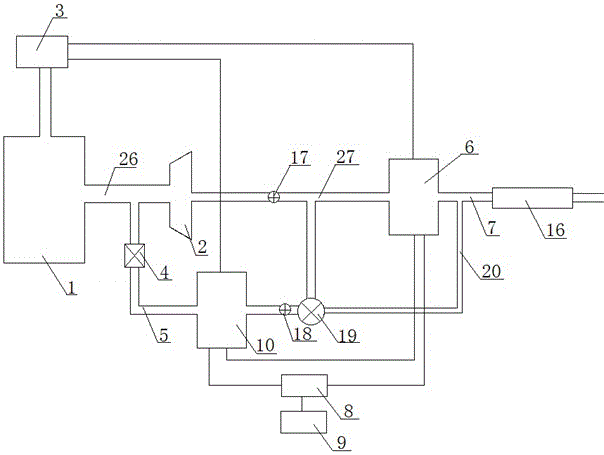

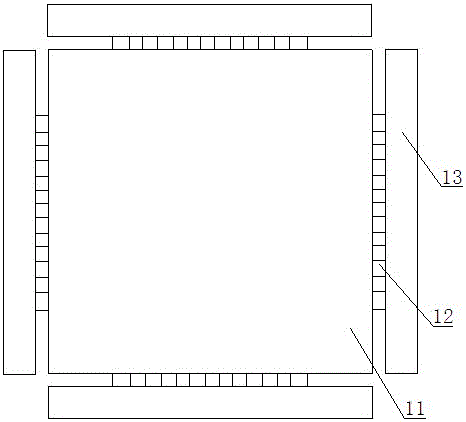

[0029] see figure 2 In this embodiment, the thermoelectric power generation device I6 or the thermoelectric power generation device II10, or the thermoelectric power generation device I6 and the thermoelectric power generation device II10 select the following thermoelectric power generation device at the same time, which includes a heat collecting gas tank 11, a power generation module 12 and a cooling water jacket 13, specifically Please refer to the content of the utility model patent "An Automobile Exhaust Temperature Difference Power Generation Device" filed by the applicant on the same day. The heat collecting end air box 11 is a masonry cylinder air box made of pure aluminum with a square cross section, the cooling end water jacket 13 is a flat cuboid made of pure aluminum, the hot end of the power generation module 12 and the heat collecting gas The outer surface of the box 1 is attached, and the cold end of the power generation module 2 is attached to the outer surfac...

Embodiment 2

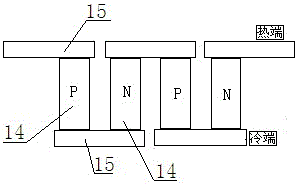

[0035] see Figure 4 , see figure 2 , in the present embodiment, the thermoelectric power generation device I6 or the thermoelectric power generation device II10, or the thermoelectric power generation device I6 and the thermoelectric power generation device II10 select the following thermoelectric power generation device simultaneously, which includes a heat collector 21, a thermoelectric power generation sheet 22 and a plurality of masonry prisms Body 23, for details, please refer to the content of the utility model patent "A Vehicle Exhaust Temperature Difference Power Generation Device" filed by the applicant on the same day. The heat collector 21 includes a hollow box body and air inlets and air outlets at both ends, and the air inlet and the air outlet of the heat collector 21 are used as the air inlet and the air outlet of the thermoelectric power generation device to collect the exhaust heat, so The plurality of masonry prisms 23 are arranged inside the box body of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com