Flue gas waste heat full recovery heat pump system and method for producing high temperature hot water

A heat pump system, flue gas waste heat technology, applied in heat recovery systems, heat pumps, refrigerators, etc., can solve the problem that flue gas and spray water cannot fully contact heat exchange, reduce the heat exchange efficiency between flue gas and spray water, The problem of low efficiency of gas waste heat recovery, etc., can improve the use value, improve the quality, and solve the effect of corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

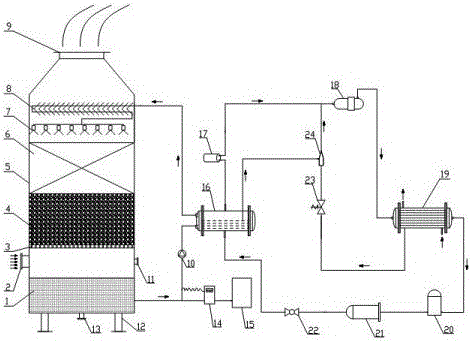

[0018] Such as figure 1 As shown, a flue gas waste heat full recovery heat pump system includes a waste heat recovery device and a water source heat pump device. The waste heat recovery device includes a spray type waste heat recovery device, a circulating water pump and a circulating water pipeline, wherein the spray type waste heat recovery device adopts a vertical cylinder body 5, and a flue gas outlet pipe 9, a multifunctional Finned mist catcher 8, spray atomizer 7, cavity heat absorption section 6, filler heat absorption section 4, filler support orifice plate 3, flue gas inlet pipe 2, spray water header 1, water replenishment inlet pipe 11 And sewage pipe 13. The lower end of the spray-type waste heat recovery device is provided with cylinder legs 12, and a circulating water pump 10 is provided on the circulating water pipe. The water source heat p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com