A Dynamic Temperature Measuring Device in High Temperature Breaking Strength Tensile Test

A tensile test and breaking strength technology, applied in the field of dynamic temperature measurement devices, can solve problems such as temperature measurement error, and achieve the effect of solving temperature measurement failure, good reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings.

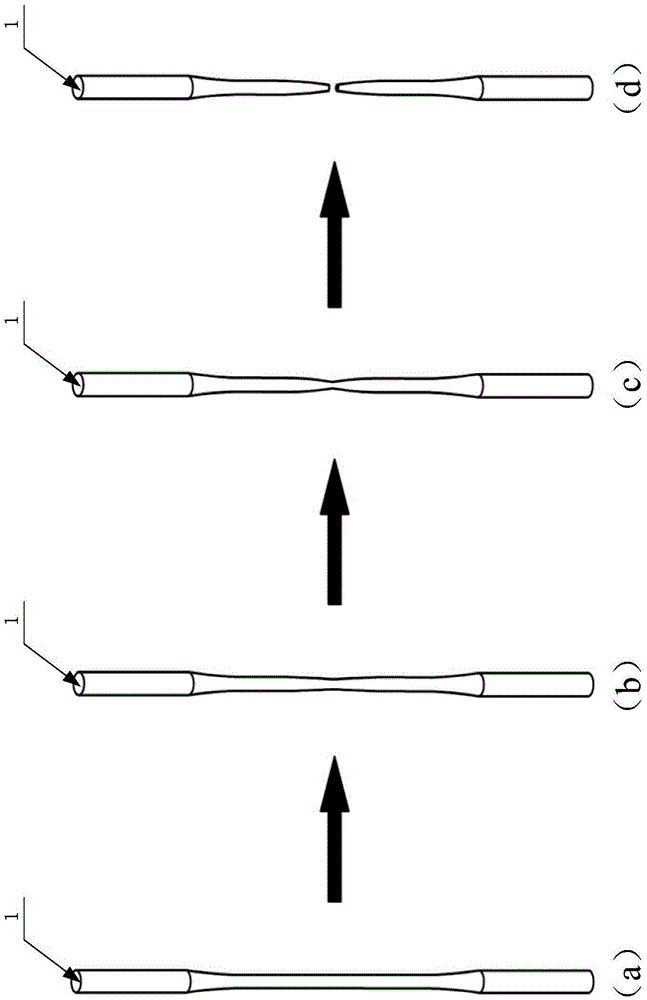

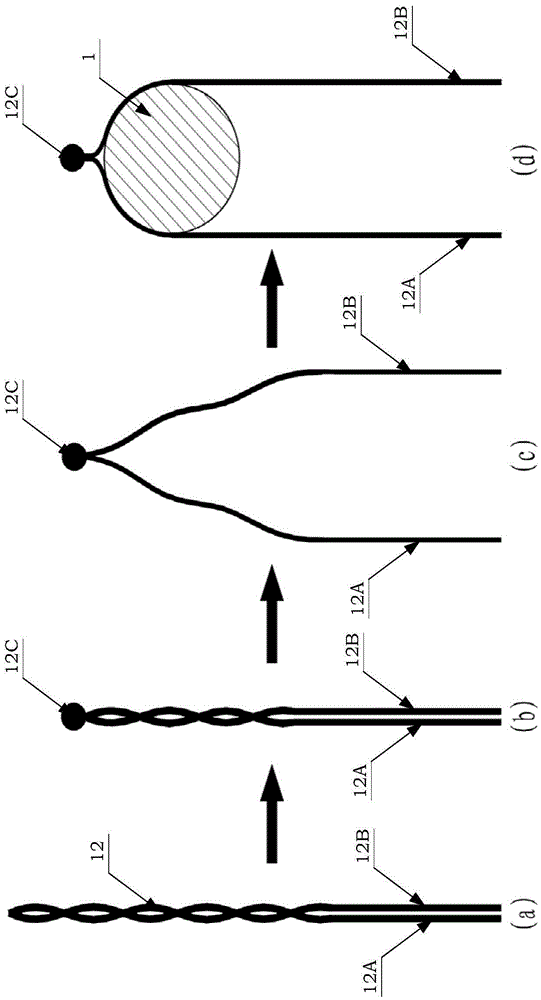

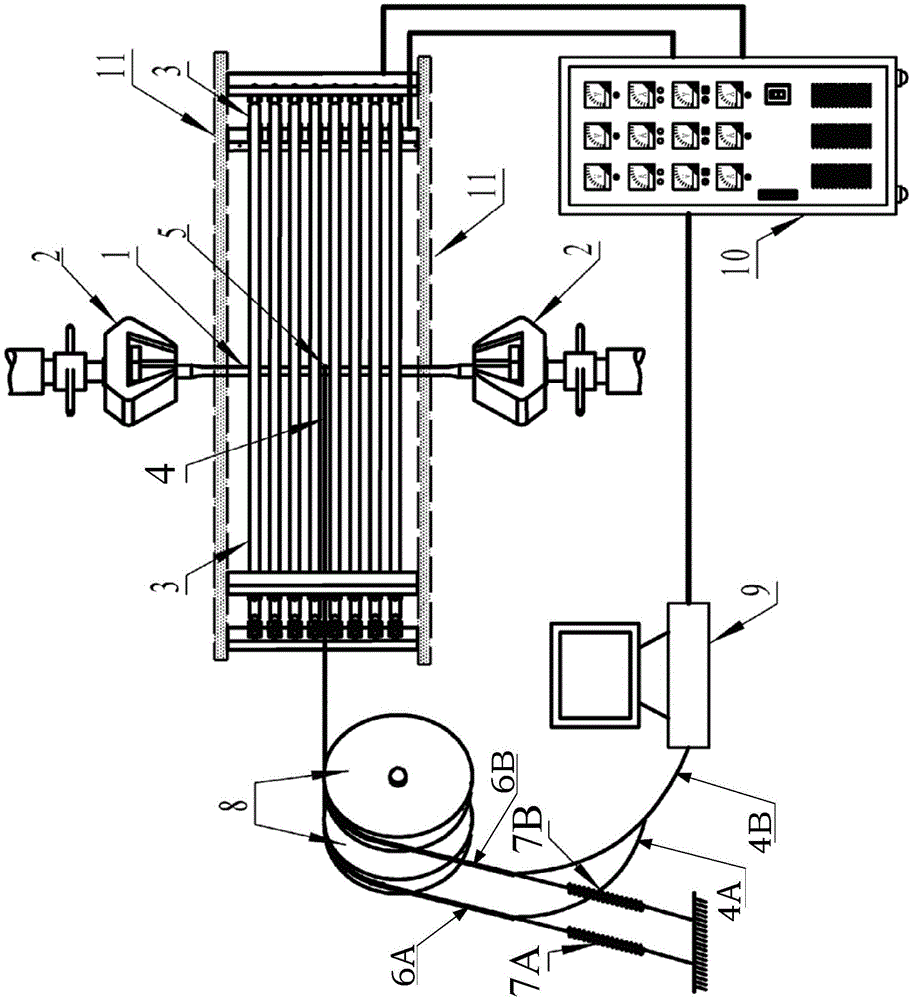

[0039] Such as image 3 As shown, a dynamic temperature measuring device in a high-temperature breaking strength tensile test designed by the present invention includes a cylindrical tensile test piece 1, a tensile testing machine chuck 2, an infrared radiation array 3, and an oblique section fitting thermoelectric Coupled temperature sensor 4, temperature measuring point 5, high temperature resistant insulating sleeve (6A, 6B), tension spring (7A, 7B), double groove fixed pulley 8, computer 9, high-power phase-shifting voltage controller 10 and light high temperature heat shield 11. Among them, the oblique section fits the thermocouple temperature sensor 4, A high temperature resistant insulating sleeve 6A, B high temperature resistant insulating sleeve 6B, double groove fixed pulley 8, A tension spring 7A and B tension spring 7B constitute the preload temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com