Industrialized mushroom production method and industrialized mushroom production system

A production method and technology of a production system, applied in the fields of botany equipment and methods, mushroom cultivation, gardening, etc., can solve the problems that plague the research of shiitake mushrooms, affect the efficiency of shiitake mushroom production, and high production costs, so as to reduce the probability of infection with miscellaneous bacteria, Reduce one bagging operation and achieve the effect of continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

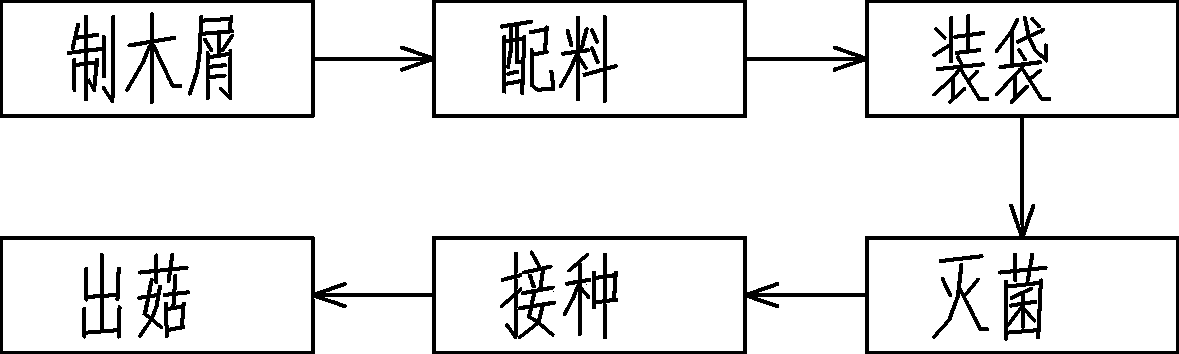

[0059] Such as figure 1 Among them, a kind of shiitake mushroom factory production method comprises the following steps:

[0060] 1. Making wood chips;

[0061] Make wood chips with particle size below 10mm;

[0062] 2. Ingredients;

[0063] Mix the sawdust with the ingredients evenly;

[0064] 3. Bagging:

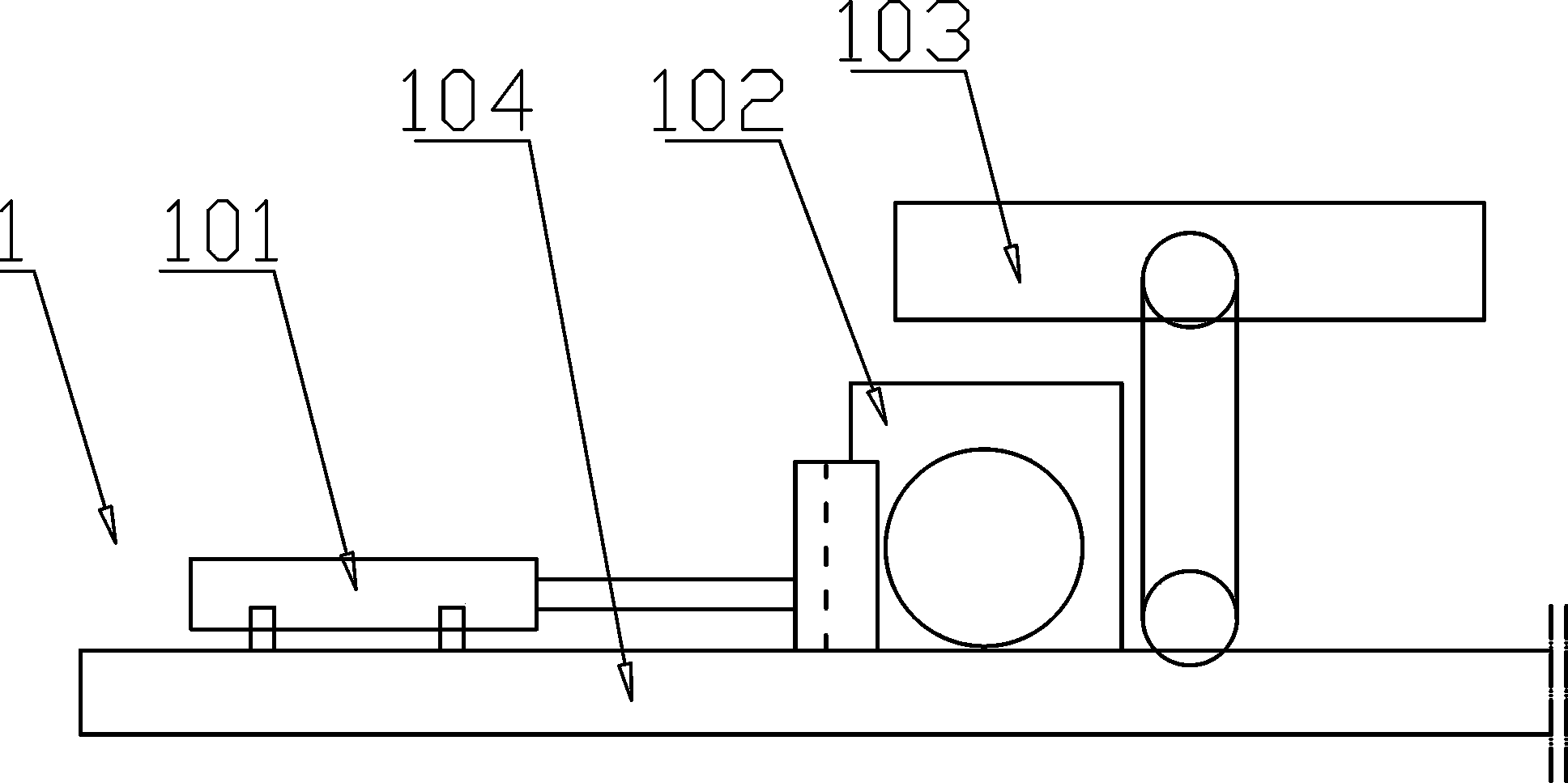

[0065] The mixed material is packed into a 20cm × 50cm polypropylene plastic bacteria cylinder by the bacteria cylinder bagging device 5 to make a bacteria cylinder, and sealed;

[0066] 4. Sterilization;

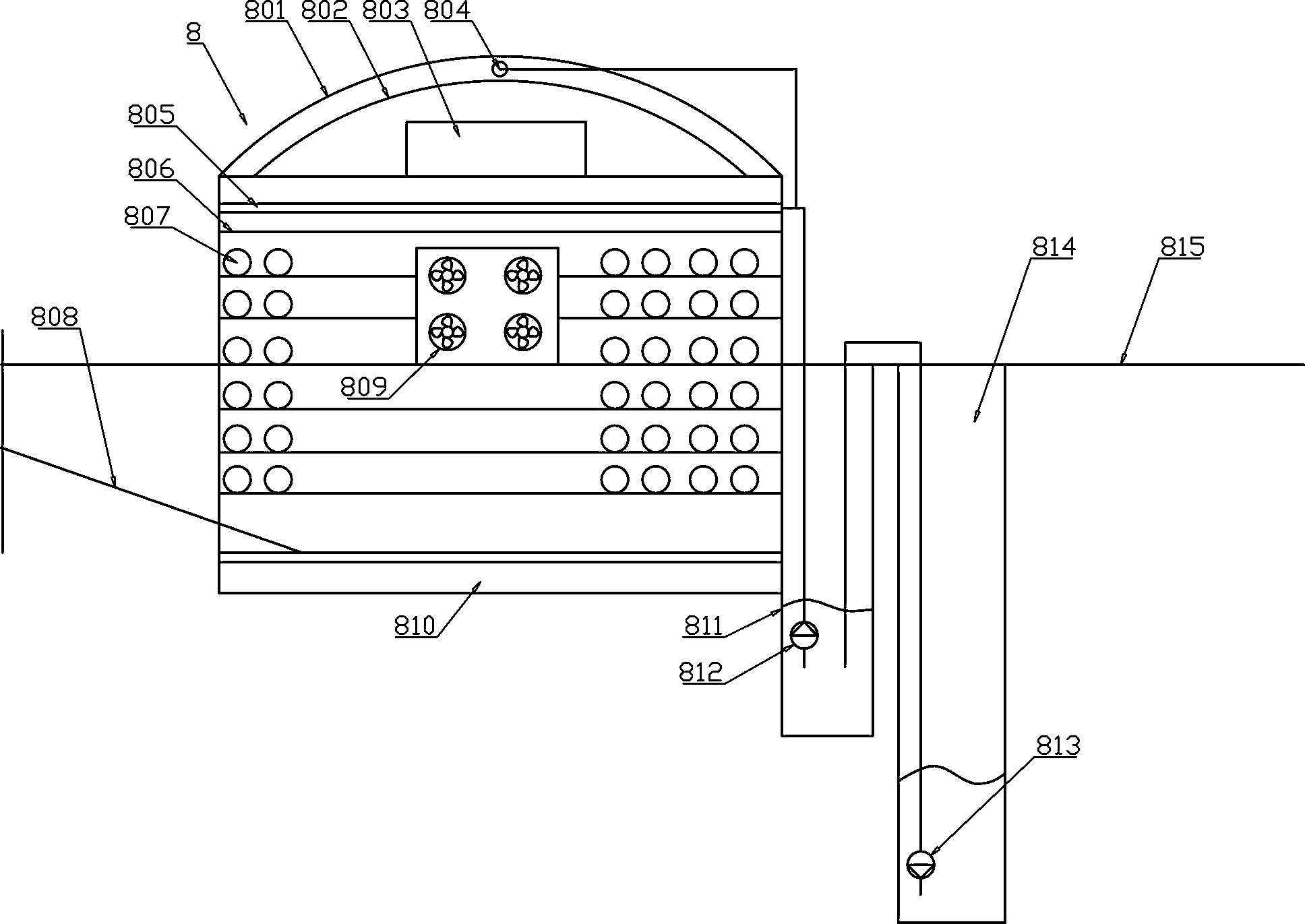

[0067] Such as Figure 9 As shown in the figure, the bacteria tube 807 is sent into the sterilization chamber 6 from the first airtight door 61 at one end of the sterilization chamber 6 to be sterilized by steam, and then sent directly from the second airtight door 62 at the other end of the sterilization chamber 6 Enter the inoculation workshop 7 and inoculate, and the top of the inoculation workshop 7 is provided with a shade layer 71, so that the bacteria tube...

Embodiment 2

[0075] Preferably on the basis of Example 1, in step 2, the materials for making the fungus cartridge 807 include the following raw materials in parts by weight: 30-80 parts of sawdust, 8-28 parts of fruit peel, pomace and / or plant straw, and water-absorbing agent 1-10 parts, 5-20 parts of bean cake powder and / or bran, 0.5-2 parts of gypsum, 0.5-2.0 parts of chitosan.

Embodiment 3

[0077] On the basis of Example 2, the further preferred technical scheme is as follows, the tested strains: the tested bacterial species: Qiuzai No. 7, which is suitable for the layered cultivation of mushrooms in autumn, and the variety shows that the mushroom body is medium and large, and the mushroom stalk is thin and short , the mushroom cover is round and thick, the fruiting temperature is 8-25 ℃, the bacterial age is 65-75 days, the fruiting is fast and the output is high.

[0078] Pretreatment of cultivation substrate: Mix 4-7mm coniferous sawdust and fruit sawdust at a ratio of 2:1, expose to the sun for 3 days, then soak in water for 24 hours, and then crush sesame straws to 80 mesh after 2-3 days of exposure, and soak in normal temperature water For 20 hours, citrus peels, grapefruit peels, and pomace are exposed to the sun and crushed to a size of 80 mesh, so that the sawdust and sesame straw are soft and fluffy, and easy to absorb water.

[0079] Mixing materials f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com